Black and white film shading curtain and preparation process thereof

A preparation process and technology of black and white film, applied in the field of black and white film shading curtains and their preparation, can solve the problems of unsatisfactory shading effect of shading curtains, unsatisfactory quality and appearance of curtains, and unsatisfactory appearance quality, etc., and achieve product style. Rich, simple structure, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

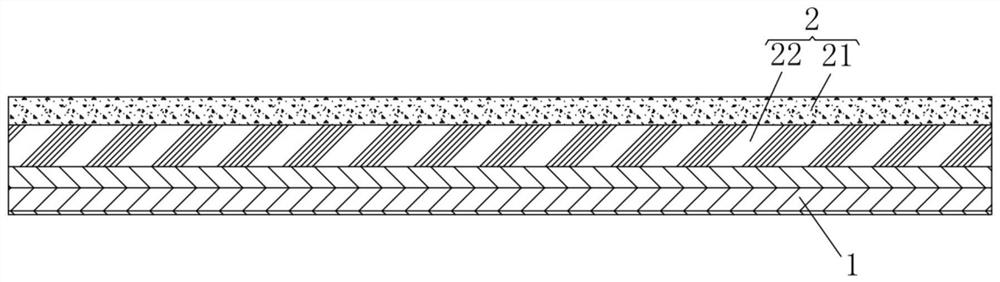

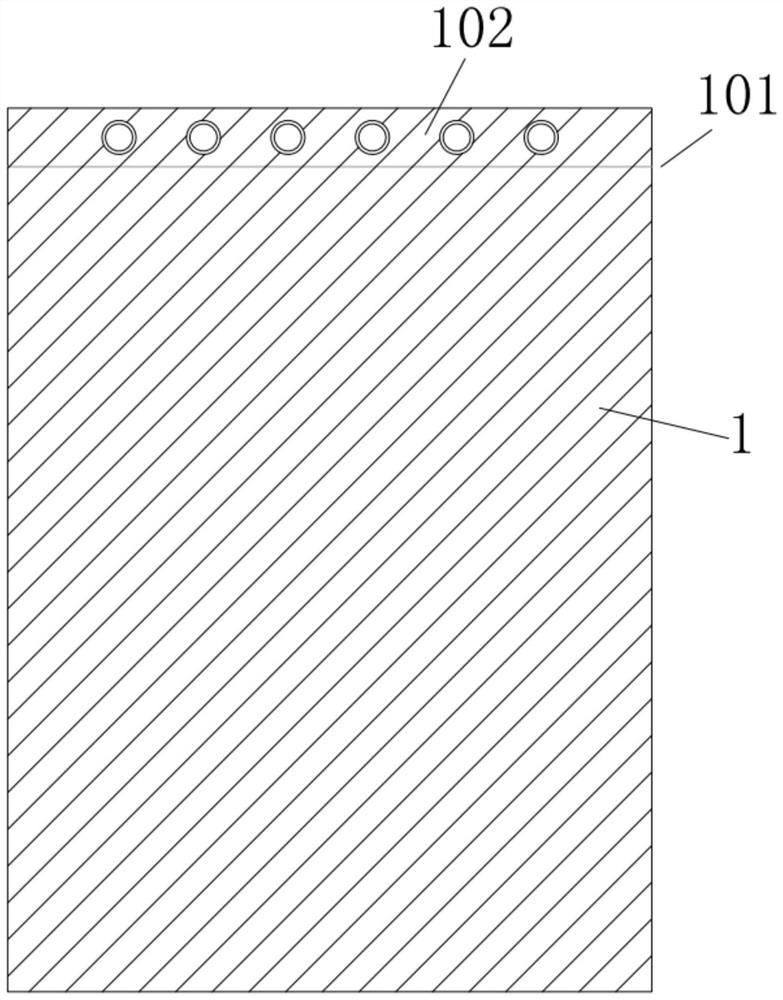

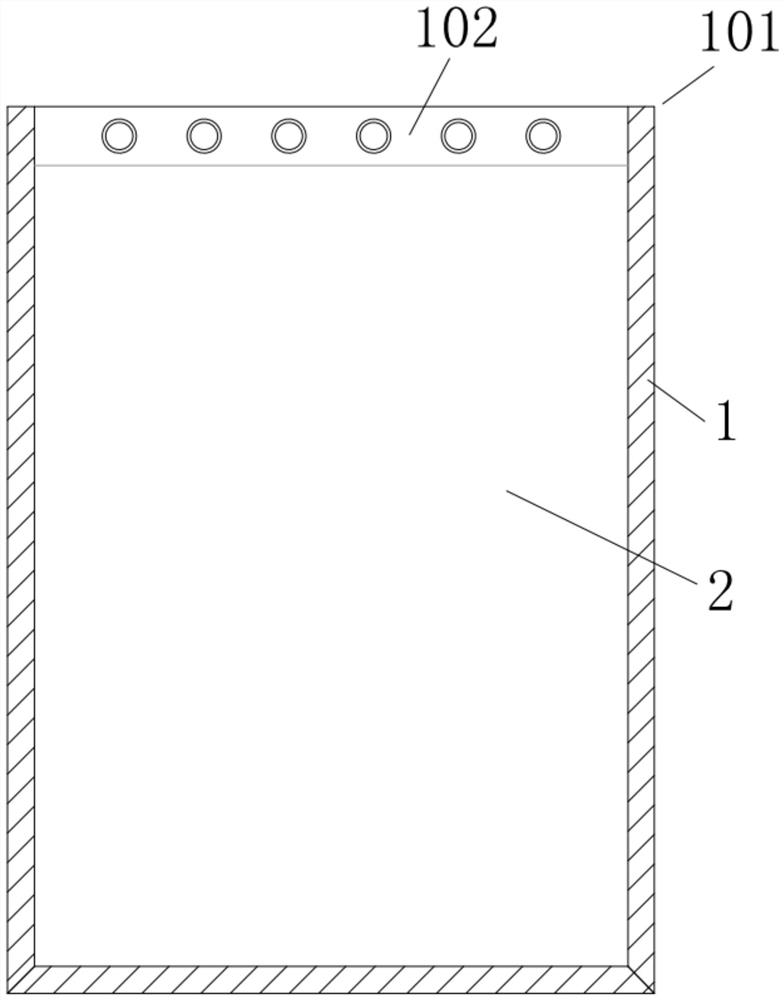

[0030] A black and white film blackout curtain, such as Figure 1 to Figure 3 and Figure 5 As shown, comprise curtain body 101, the upper end of described curtain body 101 is fixedly provided with curtain head 102, and curtain head 102 is the curtain webbing 3 that is located at curtain body 101 top or is the perforated metal ring that is evenly fixed on curtain body 101 top The curtain body 101 comprises a curtain surface 1 and a curtain lining 2; the curtain surface 1 is mainly woven or blended from one or more of cotton, hemp, polyester, and silk; the curtain lining 2. It is mainly composed of at least one layer of white base cloth 21 and at least one layer of TPU film 22 through hot melt adhesive; the TPU film 22 is a black or white waterproof and moisture-permeable film. The curtain lining 2 is compounded by hot melt adhesive (TPU). Since the hot melt adhesive and the TPU film belong to the same type of material, after compounding, the adhesiveness is high, it is not ea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com