Superheated steam steaming and baking equipment and processing control method thereof

A technology of superheated steam and steaming, which is applied to heating devices, roasters/barbecue grids, cooking utensils, etc., and can solve problems such as adjustment, loss of color, and inability to control the humidity and temperature of the steamer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

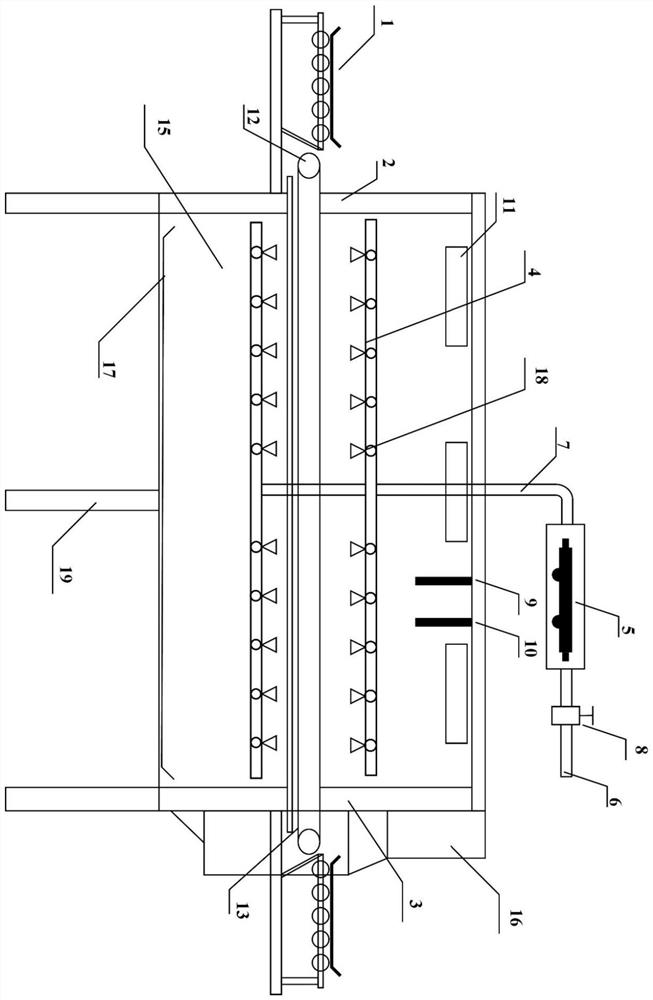

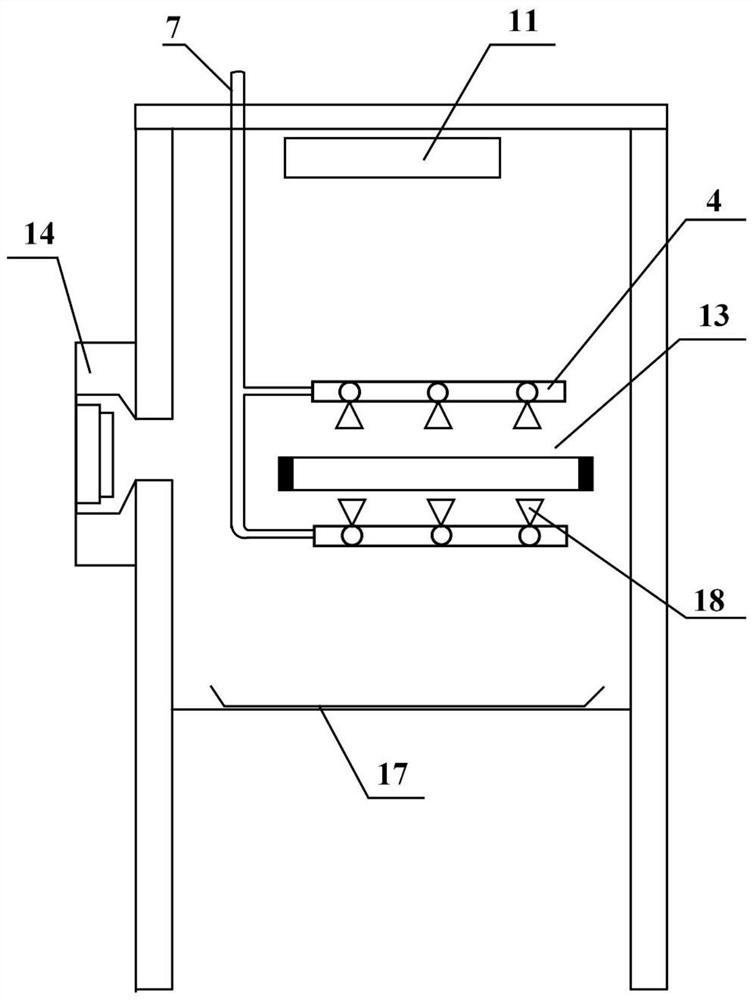

[0036] like Figure 1-2 As shown, a superheated steam steaming equipment includes a superheated steam generator 5, a superheated steam release pipe 4, a steam control valve 8, a temperature detector 9, a humidity detector 10, a cooling device 11, a transmission motor 12, and a transmission chain 13 , hot air generating device 14, steam oven body 15, controller 16 and frame 19; wherein, said controller 16 includes a start-up module, a parameter setting module, a mode selection module and a valve control module; said mode selection module includes a steamer Cook selection module and roast selection module.

[0037] The steam oven body 15 is installed on the frame 19, and the steam oven body 15 is provided with a baking pan outlet 2 and a baking pan inlet 3; The other end is located at the outlet 2 of the baking tray; the output shaft of the transmission motor 12 is connected to the transmission wheel at one end of the transmission chain 13 for driving the transmission chain 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com