Pipe-communicating three-sleeve water storage secondary heating heat exchanger

A technology of secondary heating and three casings, which is applied in the field of HVAC, can solve the problems of slow heating, low thermal efficiency, and short flow of pipes connected with large pipes and small pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

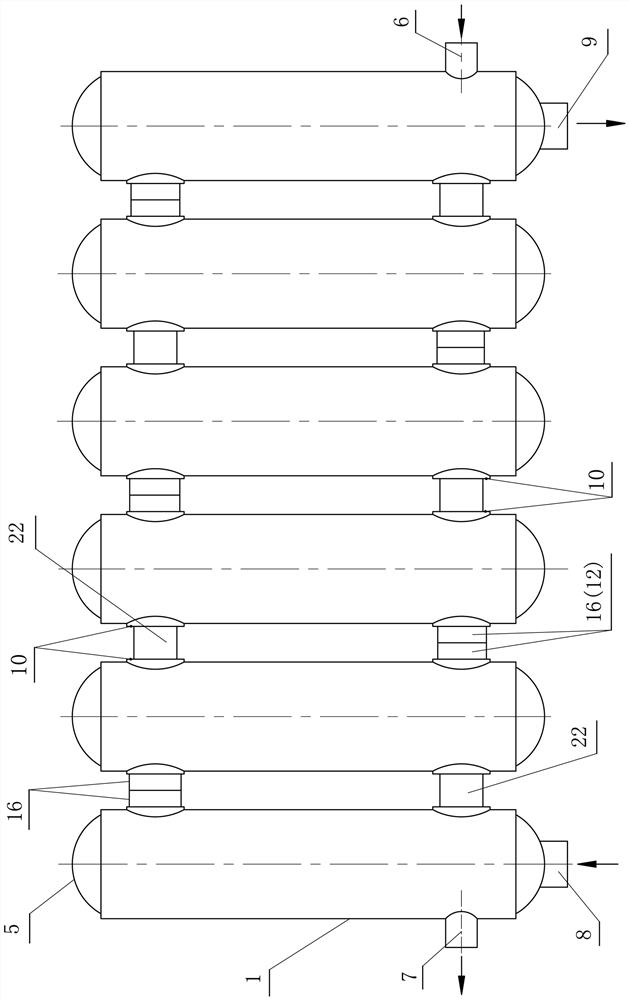

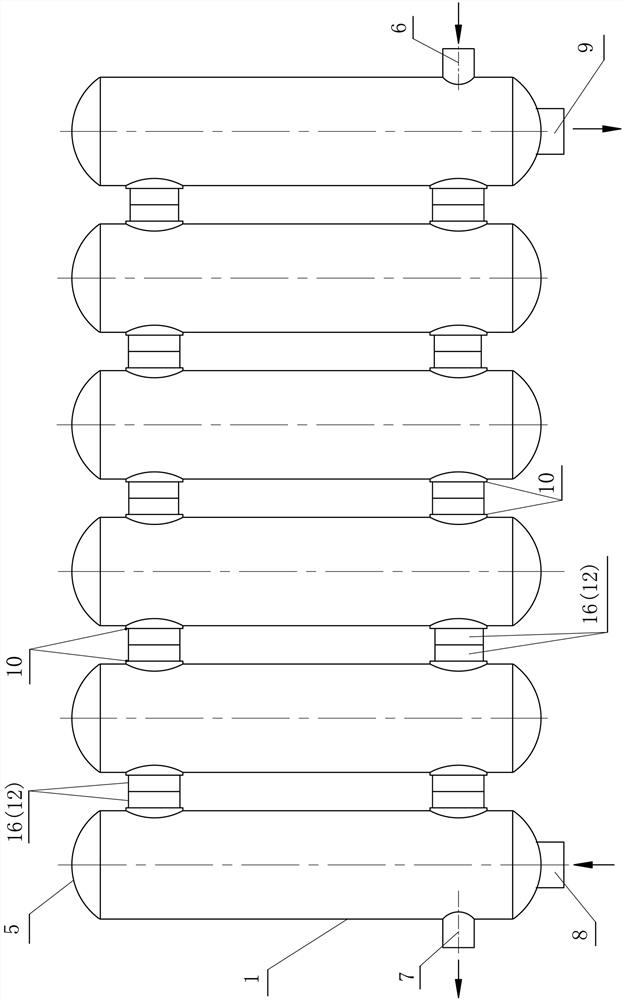

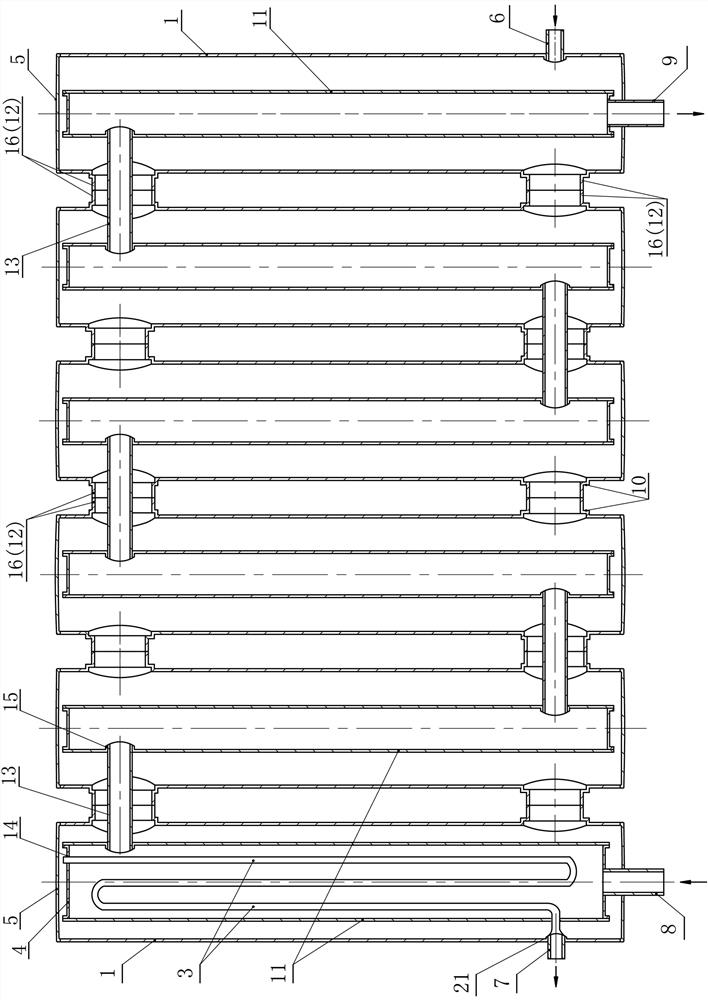

[0037] 1. In the present invention, the tube is connected to the three-tube water storage secondary heating heat exchanger, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 15 , Figure 16 As shown, the two ends of the plurality of cold water pipes 1 press the pipe wall on the arc surface to form a plane platform 10, and then set and press the shell tube flange hole 12 on the plane platform 10 successively; the shell tube flange hole 12 faces on the flat plate The outer flanging opening is a straight wall and a flat opening, which is the shell tube valgus hole 16; the shell tube valgus hole 16 is connected to the mouth of the adjacent cold water pipe 1 shell tube valgus hole 16, and the hole is directly welded to connect multiple branches The cold water pipe 1 is an integral cold medium channel, which is combined into a counterflow or mixed flow structure of cold fluid. The cold water pipes 1 that do not need openings at one end of t...

Embodiment 2

[0048] Such as image 3 , Figure 10 As shown, the heating pipe 11 arranged in the lumen of the cold water pipe 1 side is a thick pipe, and the diameter is selected to be 51-63 mm, and the straight diameter of the other heating pipes is 32-38 mm. The straight diameter of the pipe 23 is 19-25mm; the thick heating pipe 11 in the inner cavity of the cold water pipe 1 is combined with the straight pipe of the heating communication pipe or the elbow pipe of the heating communication pipe. The heating pipe is convenient to directly pass through the 8mm thin tube and the 6m long cold water heat-absorbing pipe 3 is convenient to insert and connect; when the heat exchanger is installed vertically, the thick heating pipe has a large air capacity, and the gas entering the heat exchanger from the pipe network is not easy to block the hot fluid channel , does not affect the heating fluid circulation or the advantages of convenient exhaust through the exhaust valve; in the prior art, the v...

Embodiment 3

[0053] Such as Figure 5 , Figure 6 , Figure 10 As shown, one port of the cold water heat-absorbing pipe 3 is welded and fixedly connected with the cold water pipe connecting hole 14 on one end wall of the heating pipe 11 to communicate with the lumen of the cold water pipe 1, and the other end is airtightly welded and fixedly connected to the other end wall of the heating pipe to connect the cold water outlet pipe The joint is airtightly connected with the wall of the cold water pipe 1 to form a cold medium flow channel; or the cold water pipe welding hole 14 is punched on the heating pipe blocking plate 4, and the cold water on the two ports of the cold water heat-absorbing pipe 3 and the heating pipe blocking plate 4 The pipe welding hole is welded and fixedly connected. One port communicates with the inner cavity of the cold water pipe 1, and the other port communicates with the cold water outlet pipe joint 7, the pipe wall of the cold water pipe 1 or the shell pipe hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com