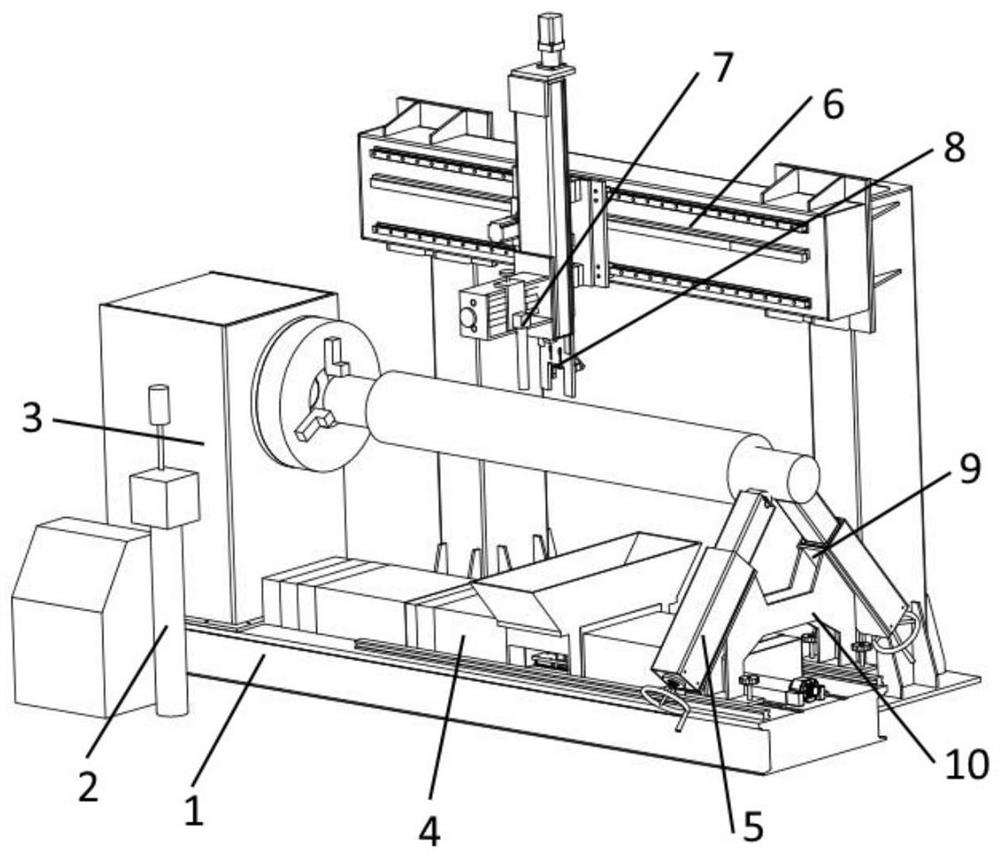

Automatic submerged arc surfacing welding equipment for roller and welding method thereof

A submerged arc surfacing and submerged arc welding technology, which is applied in the field of submerged arc welding, can solve problems such as workers falling down, pollution in the construction area, manual cleaning speed not being able to adapt to the welding speed of the device, etc., so as to avoid falling down and ensure clean and tidy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] After the applicant's research and analysis, the reason for this problem (the lumpy flux will pollute the construction area, and the lumpy flux will cause the workers to fall, thereby damaging the life and health of the workers) is that the existing buried After the arc welding device receives the welding, the flux will form lumps and be located in the welding area, and then it needs to be cleaned, but the submerged arc welding device of the transmission does not have such a function, so it can only be cleaned manually, and With the increase of the welding speed of the submerged arc welding device, the manual cleaning speed cannot adapt to the welding speed of the device, which will lead to the inability of manual cleaning to complete the cleaning work well, and then the lump flux attached to the rollers will be lost when the operator carries it. During the process, it will fall to the construction area, which will cause pollution to the construction area. In order to co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com