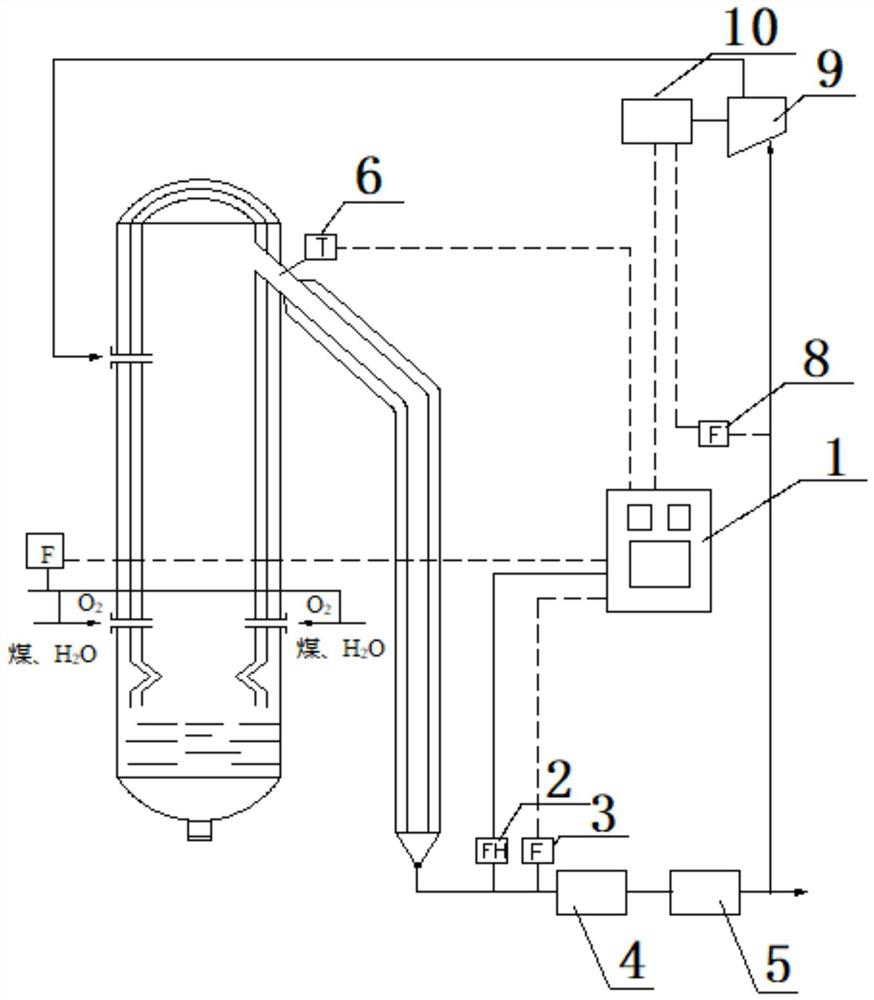

Gasification furnace load adjusting and efficiency improving system and working method thereof

A technology of gasification furnace and load, which is applied in the field of gasification furnace load adjustment and efficiency improvement system, which can solve the problems that gasification efficiency cannot be further improved, energy consumption is large, and fly ash residual carbon cannot be accurately controlled.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] The detailed parameters of a one-stage gasifier are as follows:

[0066] 1920t / d dry pulverized coal pressurized gasifier, dry basis coal carbon content 70%, fly ash output, synthesis gas flow detection device 3 measured fly ash output is 7000kg / h, fly ash residual carbon online detection device 2 The carbon residue in the fly ash was measured to be 5%.

[0067] Set 4 burners, each burner feeds 20000kg / h; each burner feeds oxygen 15200kg / h; each burner feeds steam 1638kg / h; synthesis gas specific heat λ=1.444KJ / Nm 3 ℃

[0068] After the gasification furnace load adjustment and efficiency improvement system of the present invention is started, the amount of oxygen fed to each burner increases by 93kg / h through this system, the residual carbon of fly ash drops to 1%, and the amount of chilling air increases: △M 4 =847.3Nm 3 / h, the effective gas volume increases by 470Nm 3 / h.

Embodiment 2

[0070] 1920t / d dry pulverized coal pressurized gasifier, the carbon content of dry coal is 70%, set 4 burners, each burner feeds 20000kg / h; each burner feeds oxygen 15200kg / h; each burner Mouth plus steam 1638kg / h; synthesis gas specific heat λ=1.444KJ / Nm 3 ℃. Now adjust the gasifier to 80% working condition. Turn on the gasification furnace load adjustment and efficiency improvement system of the present invention, through this system, the amount of oxygen fed to each burner is reduced by 3690kg / h, the residual carbon of fly ash is reduced to 1%, and the amount of chilling air is reduced: △ m 4 =45294Nm 3 / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com