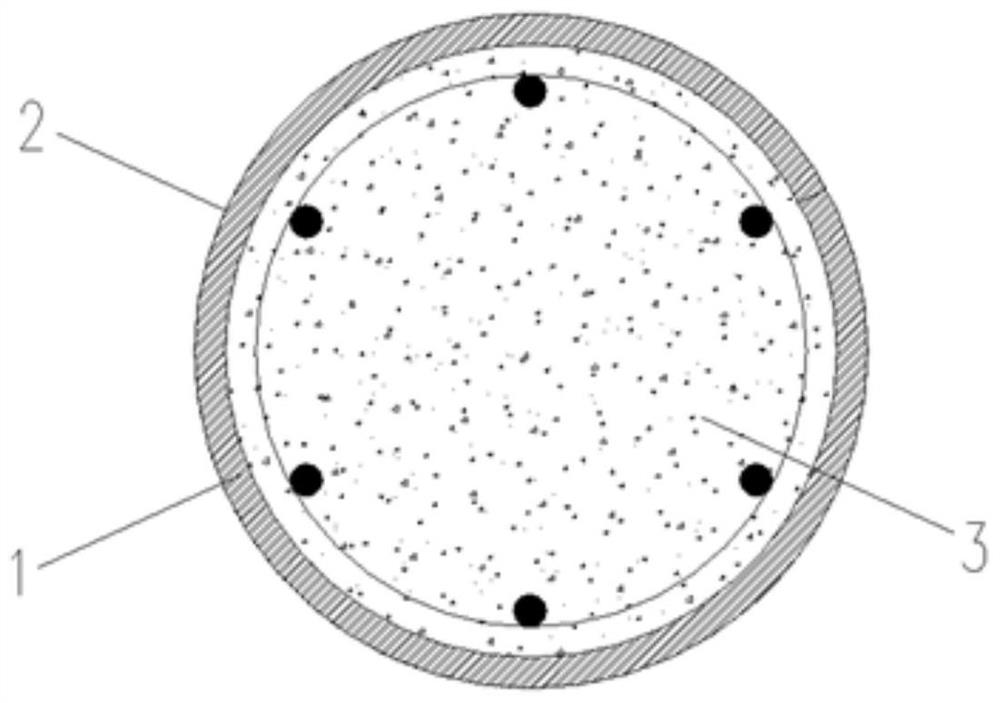

Fiber reinforced plastic and ultra-high performance concrete pipe filled common concrete combined column and production method thereof

A fiber-reinforced material, ordinary concrete technology, applied in the direction of columns, piers, pillars, etc., can solve the problems of interface bonding failure between steel pipes and concrete, low bearing capacity, poor corrosion resistance and fire resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Quartz sand is continuously assembled from 6 mesh to 150 mesh, of which, 6 mesh to 10 mesh, 80 mesh to 150 mesh account for 5% respectively, 10 mesh to 18 mesh, 18 mesh to 35 mesh, and 35 mesh to 80 mesh account for 5%. 30% respectively;

[0039] The steel fiber is a hook-shaped copper-plated microwire with a length of 13mm, a diameter of 0.22mm, a tensile strength greater than 2000MPa, and a steel fiber volume content of 2.0%;

[0040] The number of layers of carbon fiber cloth is 1 layer, covered with strips, the length is 600mm, the overlapping length is 130mm, the width of the strips is 20mm, and the spacing is 30mm.

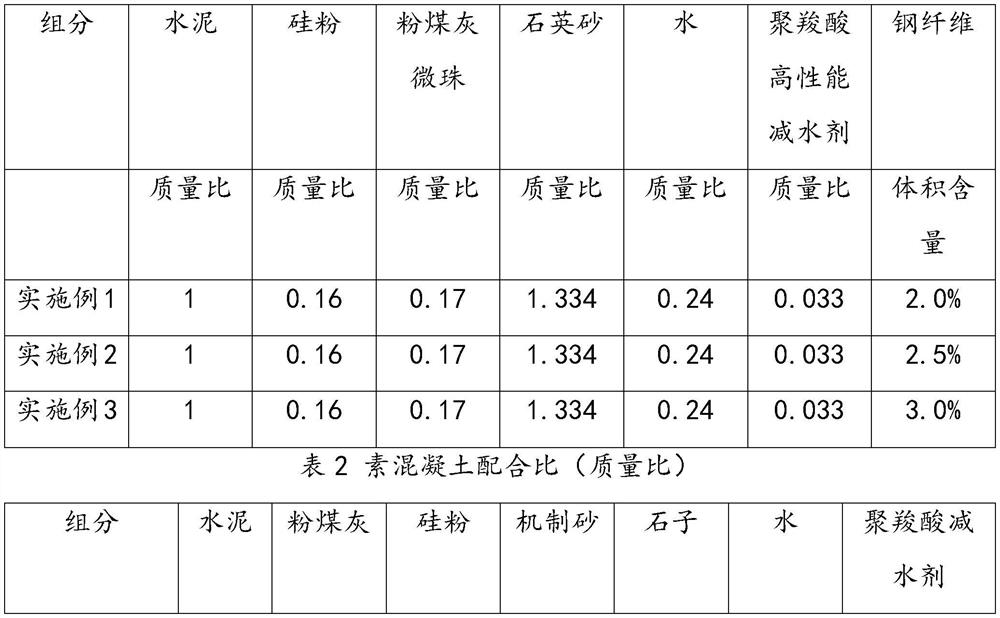

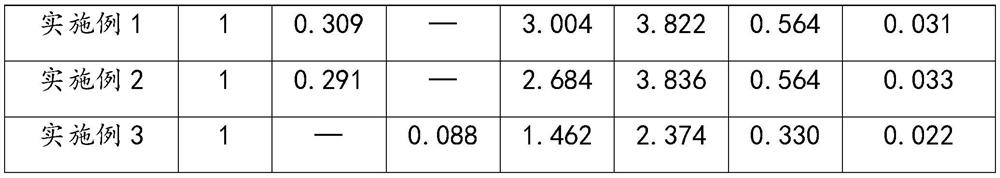

[0041] The ratio of raw material components for ultra-high performance concrete pipes is shown in Table 1; the design strength grade of core cast-in-place concrete is C30, and the ratio of raw material components is shown in Table 2.

Embodiment 2

[0043] Quartz sand is continuously assembled from 6 mesh to 150 mesh, of which, 6 mesh to 10 mesh, 80 mesh to 150 mesh account for 5% respectively, 10 mesh to 18 mesh, 18 mesh to 35 mesh, and 35 mesh to 80 mesh account for 5%. 30% respectively;

[0044] The steel fiber is a hook-shaped copper-plated microwire with a length of 13mm, a diameter of 0.22mm, a tensile strength greater than 2000MPa, and a steel fiber volume content of 2.5%;

[0045] The number of layers of carbon fiber cloth is 2 layers, wrapped in strips, the length is 600mm, the overlapping length is 130mm, the width of the strips is 20mm, and the spacing is 30mm.

[0046] Table 1 shows the ratio of raw material components for ultra-high performance concrete pipes; the design strength grade of core cast-in-place concrete is C50, and the ratio of raw material components is shown in Table 2.

Embodiment 3

[0048]Quartz sand is continuously assembled from 6 mesh to 150 mesh, of which, 6 mesh to 10 mesh, 80 mesh to 150 mesh account for 5% respectively, 10 mesh to 18 mesh, 18 mesh to 35 mesh, and 35 mesh to 80 mesh account for 5%. 30% respectively;

[0049] The steel fiber is a hook-shaped copper-plated microwire with a length of 13mm, a diameter of 0.22mm, a tensile strength greater than 2000MPa, and a steel fiber volume content of 3.0%;

[0050] The number of layers of carbon fiber cloth is 1 layer, fully covered, the length is 600mm, and the lap length is 130mm.

[0051] Table 1 shows the ratio of raw material components for ultra-high performance concrete pipes; the design strength grade of core cast-in-place concrete is C80, and the ratio of raw material components is shown in Table 2.

[0052] Table 1 Mixing ratio of raw materials for ultra-high performance concrete pipes

[0053]

[0054]

[0055] A method for producing a composite column filled with fiber-reinforced...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com