Leveling supporting leg

A leveling and nut technology, applied in the direction of controlling mechanical energy, electrical components, electromechanical devices, etc., can solve the problems of reducing the impact force of the leveling legs, and the locking of the rear legs, so as to reduce the starting torque and avoid the screw lock. Dead, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

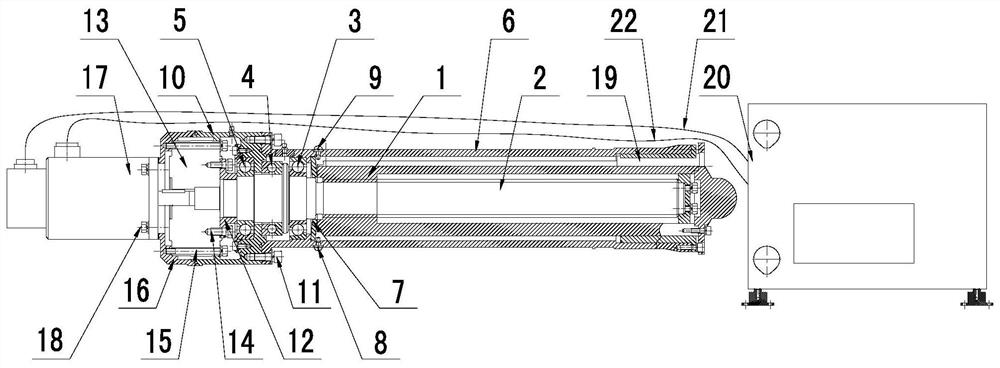

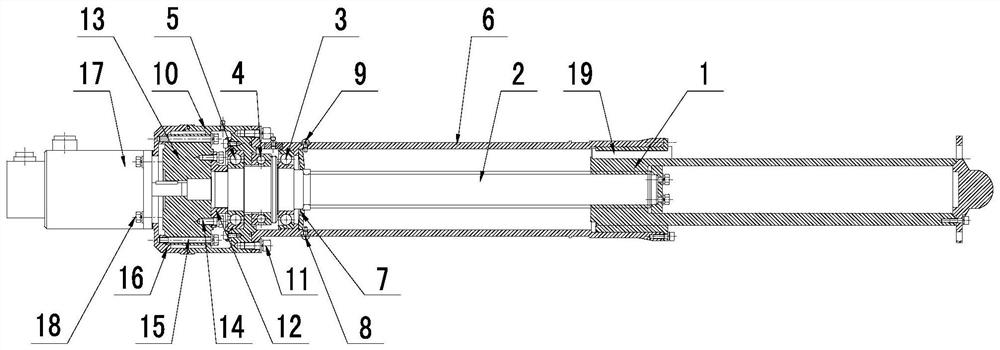

[0019] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0020] like Figure 1 to Figure 4 As shown, a leveling support leg of the present invention includes a strut nut 1, a housing 6, a butterfly spring 7, a screw rod 2, a fixing screw, and a key 19, wherein the strut nut 1 is installed on the outside of the screw rod 2, and the housing Body 6 afterbody and strut nut 1 are provided with groove, and key 19 is installed in the groove, and key 19 can prevent strut nut 1 from rotating, and strut nut 1 can only reciprocate axially. The butterfly spring 7 is fixedly installed on the housing 6 by fixing screws, so that the strut nut 1 slides backward and gradually squeezes the butterfly spring 7 when the stroke end of the leg is leveled. The butterfly spring 7 is subjected to axial load Compression deformation occurs, and as the amount of compression deformation increases, the axial load it bears is gre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com