Planetary gearbox for hydraulic and pneumatic power tong

A gearbox and planetary technology, applied to components with teeth, transmission parts, belts/chains/gears, etc., can solve the problems of fast wear of pneumatic tire clutches, frequent replacement, large gearbox volume, etc., and achieve good damping The effect of shock absorption capacity and high load-carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

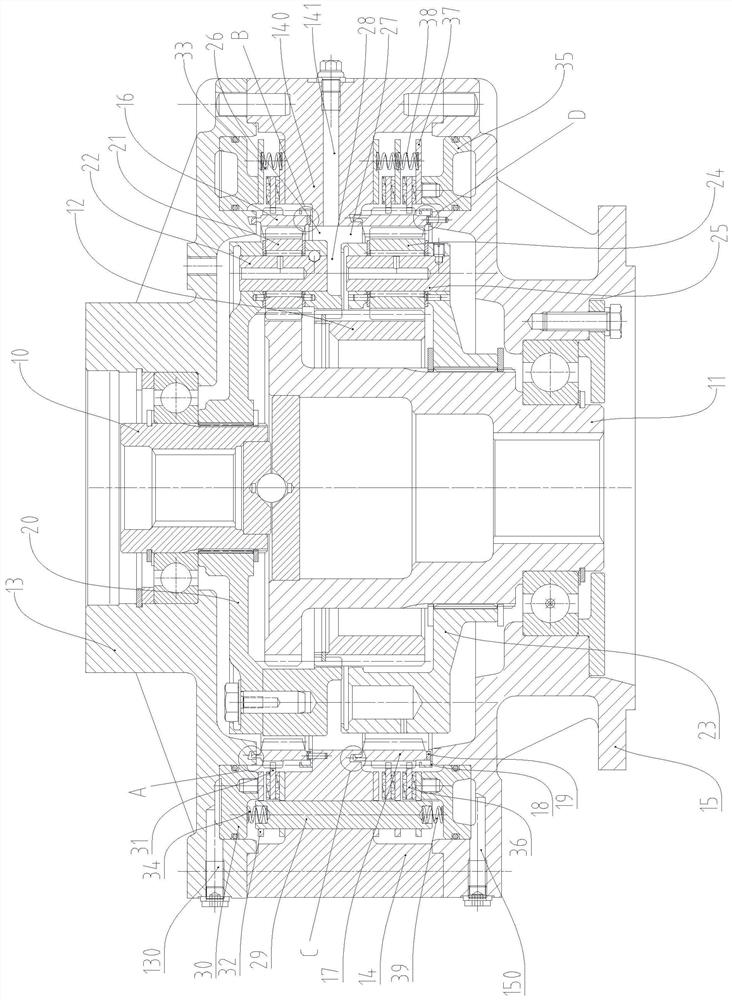

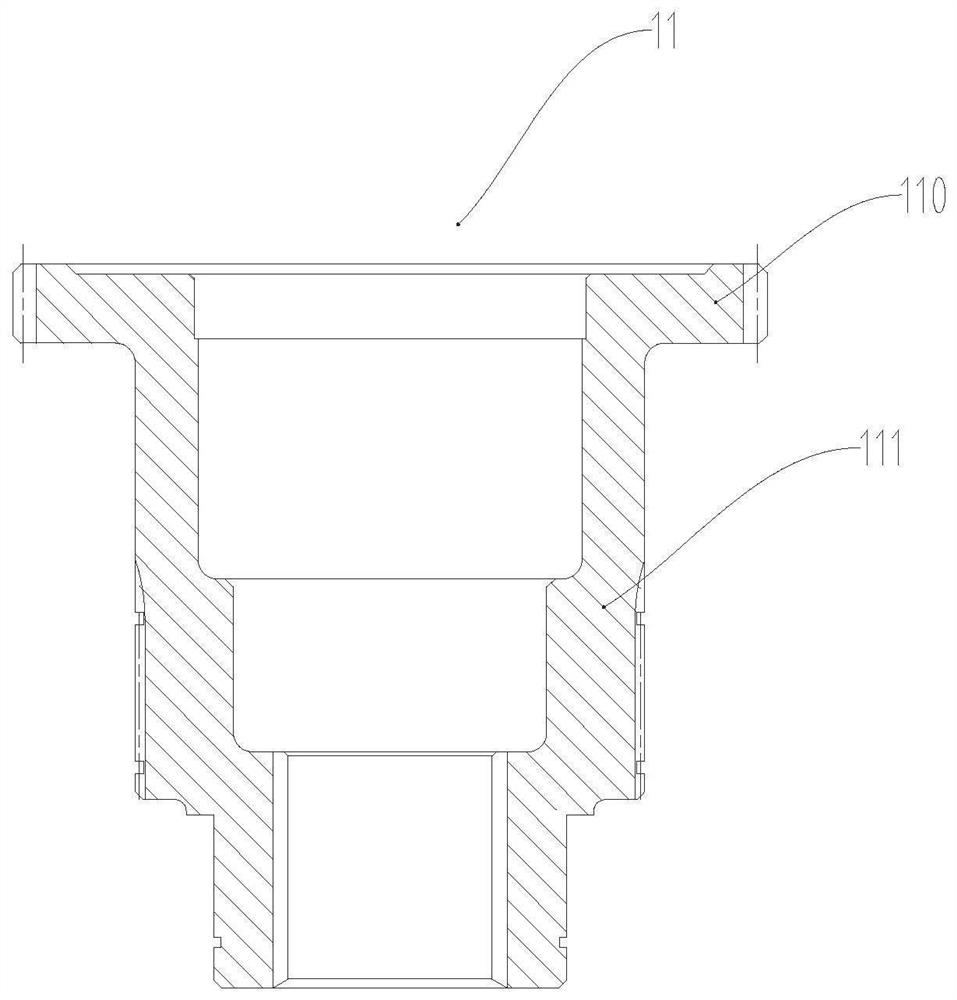

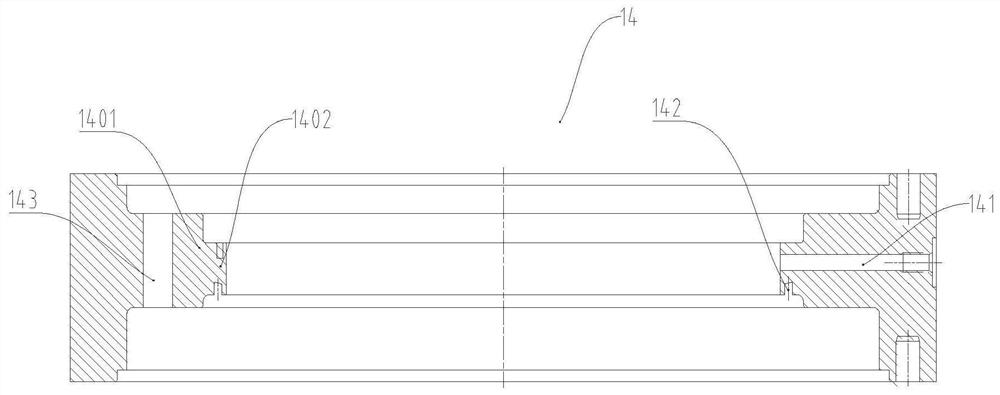

[0046] Such as figure 1 A planetary gearbox for hydraulic tongs is shown, including a box assembly and an input shaft 10, an output shaft 11, a first planetary gear 21 series, and a second planetary gear 24 series installed on the box body assembly. , connecting frame 12, low-speed gear clutch and high-speed gear clutch, described low-speed gear clutch and high-speed gear clutch all adopt dry-type pneumatic friction clutch, and described box assembly includes upper end cover 13, main box body 14 and lower end cover fixedly connected 15: The input shaft 10 is installed on the upper end cover 13, the output shaft 11 is installed on the main box body 14 and the lower end cover 15, the input shaft 10 and the output shaft 11 are coaxially distributed, and the connecting frame 12 is empty Sleeved on the output shaft 11, the first planetary gear 21 and the second planetary gear 24 are respectively located on the upper part and the lower half of the main box 14, and the first planetar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com