Rock structural surface cyclic shearing device and test method of opposite-vertex clamping structure

A technology of clamping structure and shearing device, which is applied in the direction of testing material strength by applying stable shear force, measuring device, and testing material strength by applying repetitive force/pulsation force, which can solve the problem of affecting test accuracy, shaking, etc. problem, to improve test accuracy and avoid shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

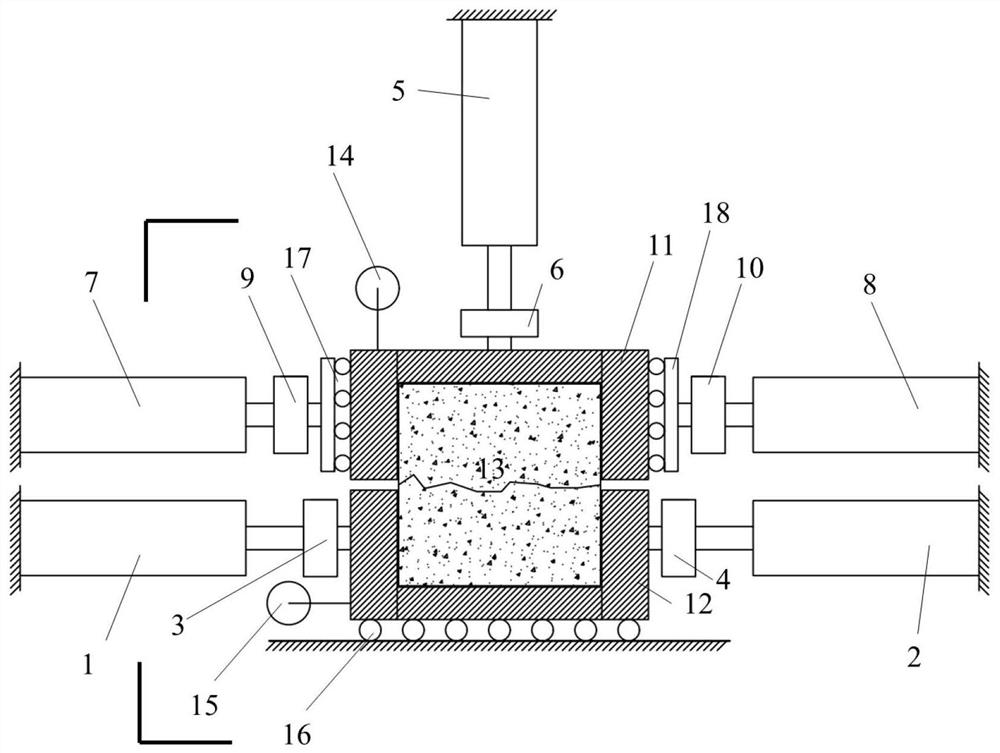

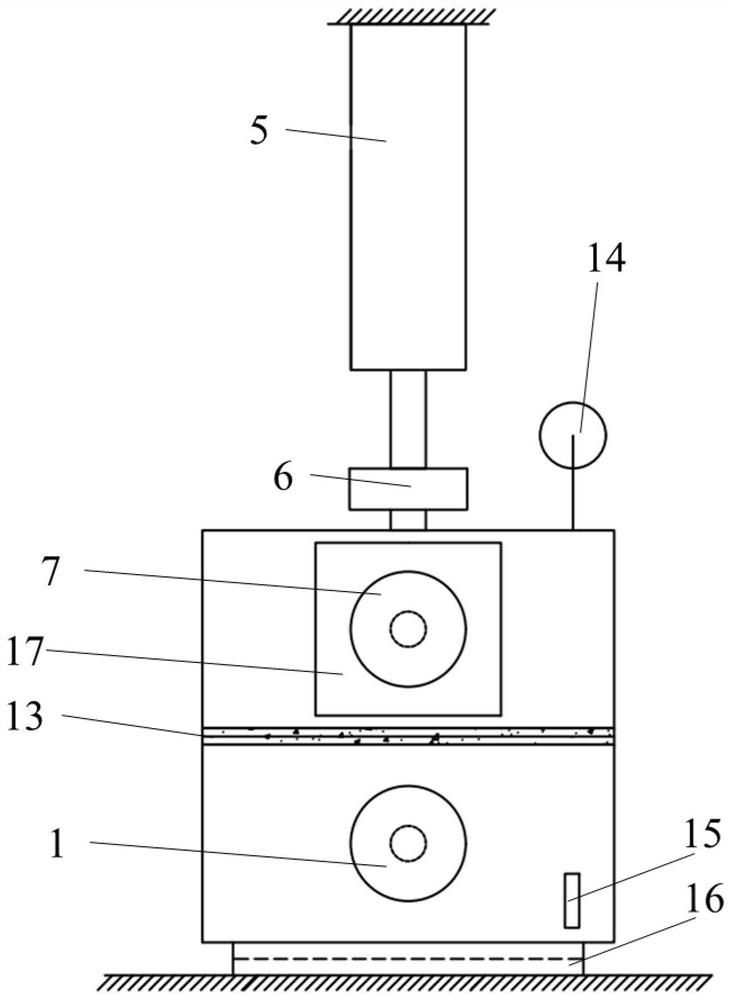

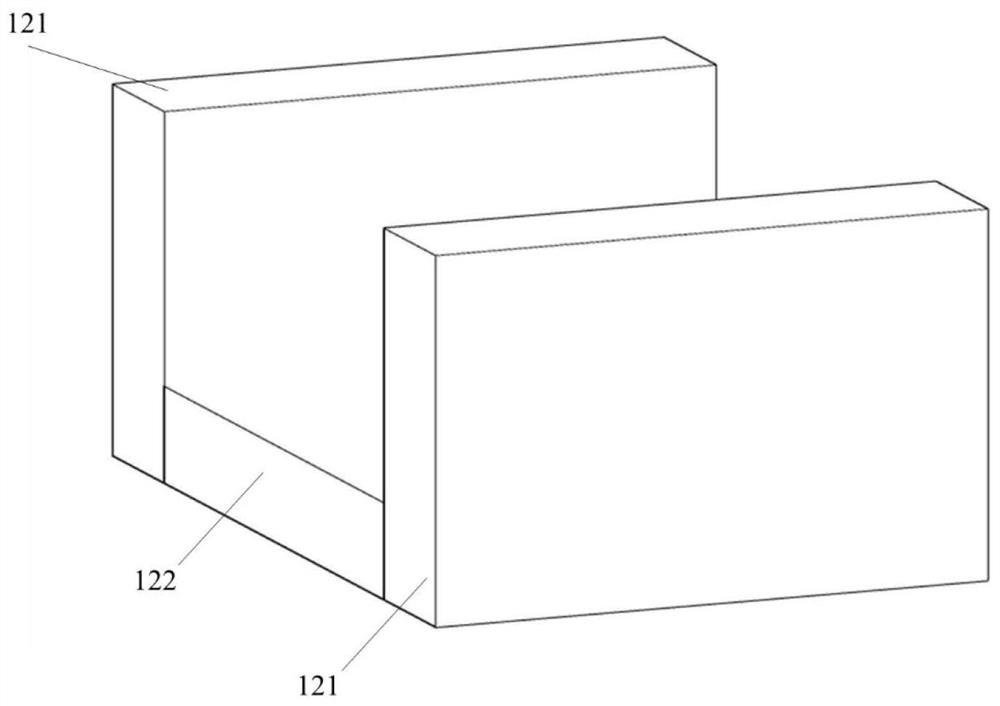

[0034] A cyclic shearing device for a rock structural surface with a top clamping structure, including an upper shear box 11 and a lower shear box 12, and an upper positive shear loading jack 7 symmetrically arranged on both sides of the upper shear box 11 And the upper negative shear loading jack 8, also includes the lower positive shear loading jack 1 and the lower negative shear loading jack 2 symmetrically arranged on both sides of the lower shear box 12,

[0035] The telescoping end of the upper positive shear loading jack 7 is provided with an upper forward shear force sensor 9 and is connected to the connecting portion of the first upper roller support 17, and the roller portion of the first upper roller support 17 is connected to the upper shear load. One side of the box 11 is offset; the telescopic end of the upper negative shear load jack 8 is provided with an upper negative shear force sensor 10 and is connected with the connecting portion of the second upper roller ...

Embodiment 2

[0048] A method for cyclic shearing test of a rock structural surface with a clamping structure against the top, utilizing the cyclic shearing device for a structural surface of rock with a clamping structure against the top described in Example 1, comprising the following steps:

[0049] Step 1. Assemble the cyclic shearing device for the rock structural surface of the top-to-top clamping structure;

[0050] Step 2, ensure that the telescopic ends of the lower positive shear loading jack 1, the lower negative shear loading jack 2, the upper positive shear loading jack 7, and the upper negative shear loading jack 8 are retracted;

[0051] Step 3, install the rock mass structural surface sample 13 between the upper shear box 11 and the lower shear box 12, and set the upper shear box 11, the rock mass structural surface sample 13 and the lower shear box 12 in a horizontal On the roller support 16;

[0052] Step 4, manually aligning the upper shear box 11 and the lower shear box...

Embodiment 3

[0059] A method for cyclic shearing test of a rock structural surface with a clamping structure against the top, utilizing the cyclic shearing device for a structural surface of rock with a clamping structure against the top described in Example 1, comprising the following steps:

[0060] Step 1. Assemble the cyclic shearing device for the rock structural surface of the top-to-top clamping structure;

[0061] Step 2, ensure that the telescopic ends of the lower positive shear loading jack 1, the lower negative shear loading jack 2, the upper positive shear loading jack 7, and the upper negative shear loading jack 8 are retracted;

[0062] Step 3, install the rock mass structural surface sample 13 between the upper shear box 11 and the lower shear box 12, and set the upper shear box 11, the rock mass structural surface sample 13 and the lower shear box 12 in a horizontal On the roller support 16;

[0063] Step 4, manually aligning the upper shear box 11 and the lower shear box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com