Dish-washing machine and control method thereof

A control method and technology for dishwashers, applied to tableware washing machines/rinsing machines, tableware washing machines/rinsing and rinsing machine parts, cleaning equipment, etc., can solve the problem of easily accumulating scale and affecting the steam sterilization effect of dishwashers To achieve the effect of improving the sterilization and disinfection effect, improving the steam generation efficiency and sterilization and disinfection effect, and improving the service life and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

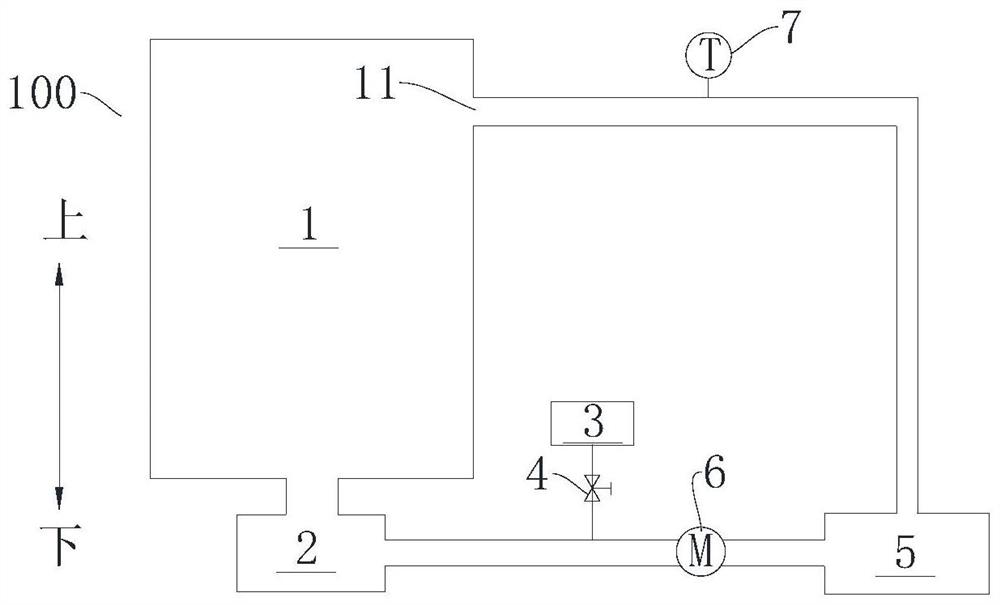

[0052] Specifically, such as figure 1 As shown, the dishwasher 100 of this embodiment includes: an inner container 1, a steam sterilizing device 5, a descaling device 3 and a control device.

[0053] Wherein, the peripheral wall of the inner tank 1 is formed with a steam injection port 11, the bottom of the inner tank 1 is provided with a water cup 2, the steam sterilizing device 5 has a steam generating chamber, the steam generating chamber communicates with the water cup 2, and the steam generator includes: a plurality of heating Tube.

[0054] The descaling device 3 may include: a housing box and a control valve 4, the housing box defines a housing chamber, the housing chamber accommodates descaling agents such as citric acid and other descaling agents, the housing chamber has an insertion port, and the insertion port communicates with the steam generation chamber, The control valve 4 is arranged at the delivery port to control the on-off of the delivery port.

[0055] Th...

Embodiment 2

[0057] The dishwasher 100 of this embodiment includes: an inner container 1 , a steam sterilizing device 5 , a descaling device 3 and a control device.

[0058] Wherein, the top wall of the inner tank 1 is formed with a steam injection port 11, the bottom of the inner tank 1 is provided with a water cup 2, the steam generating device is arranged on the top of the inner tank, and the steam sterilizing device 5 has a steam generating chamber, and the steam generating chamber and the water cup 2 communication, the steam generator includes: multiple heating tubes.

[0059] The descaling device 3 may include: a housing box and a control valve 4, the housing box defines a housing chamber, the housing chamber accommodates descaling agents such as citric acid and other descaling agents, the housing chamber has an insertion port, and the insertion port communicates with the steam generation chamber, The control valve 4 is arranged at the delivery port to control the on-off of the deliv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com