Aluminum electrolysis cell lining waste cathode carbon block crushing device

A waste cathode carbon block and crushing device technology, which is applied in the direction of grain processing, etc., can solve the problems of uneven carbon block size, unsatisfactory crushing effect, and low work efficiency, and achieve simple structure, improved crushing effect, and improved work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

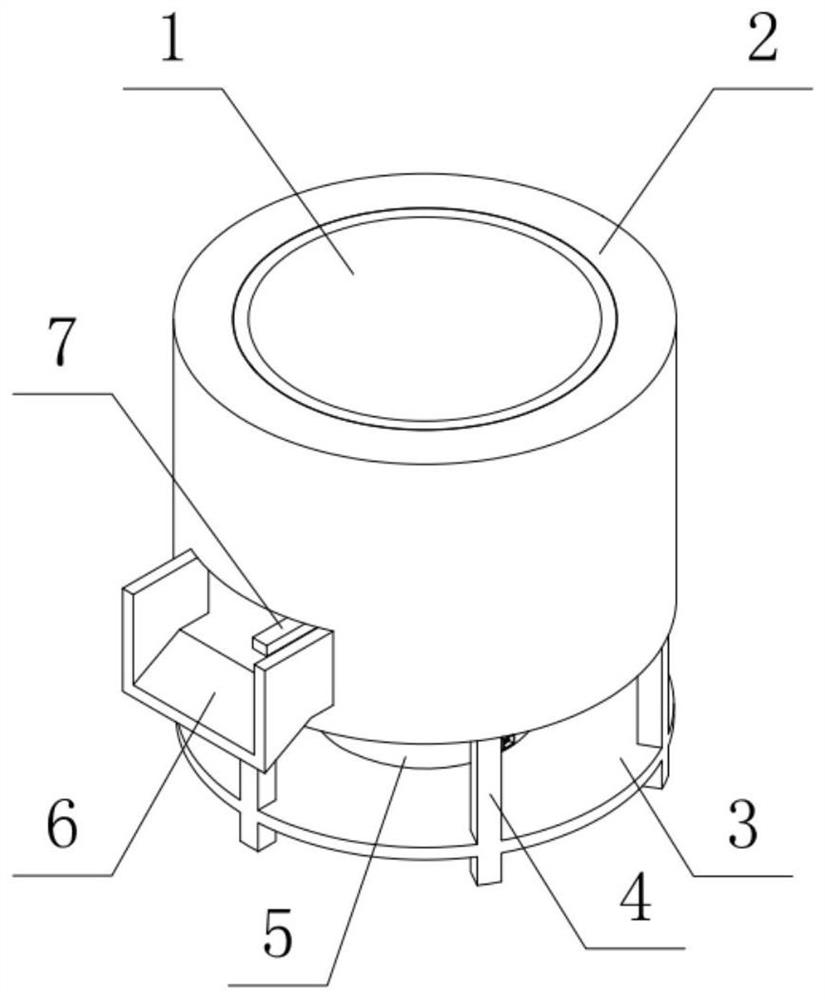

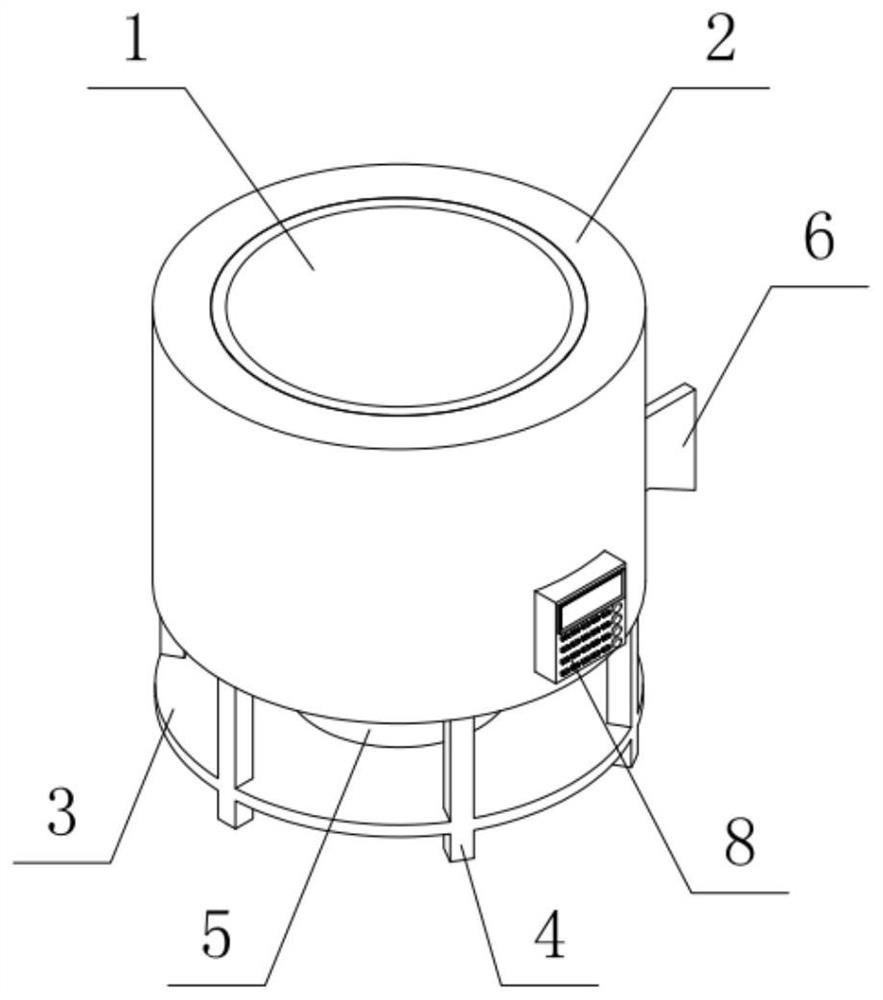

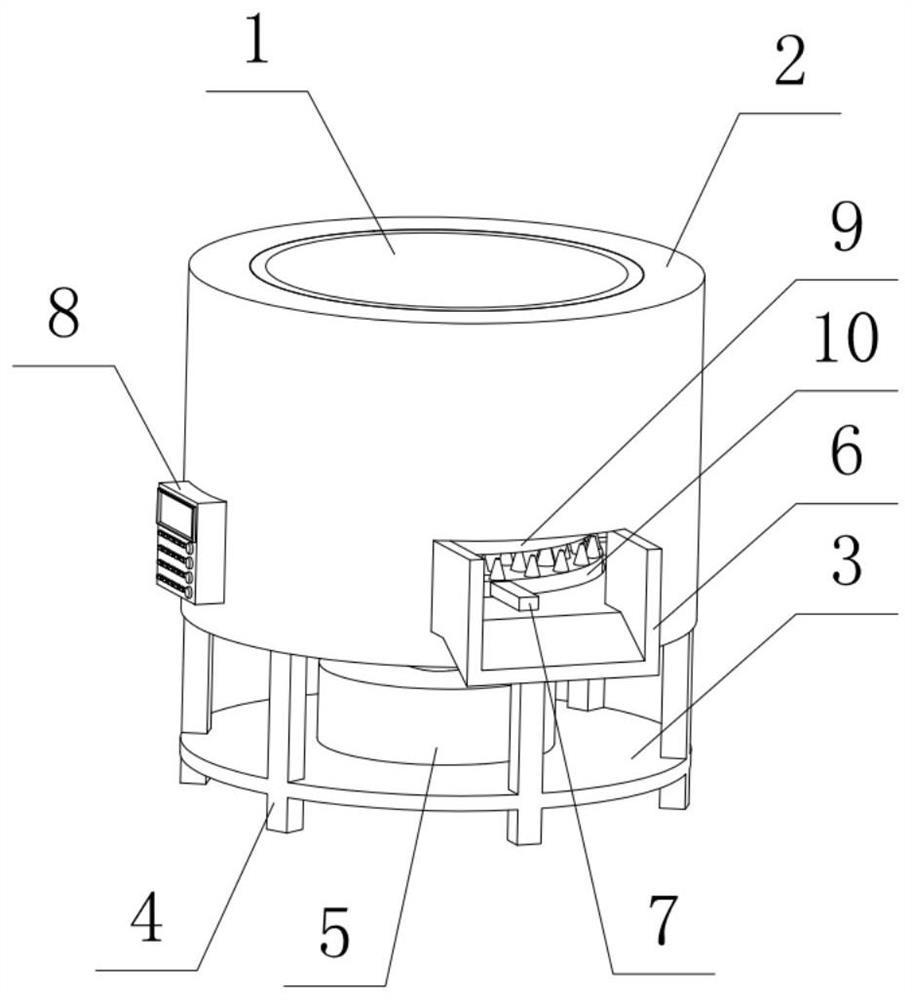

[0035] Such as Figure 1-4 As shown, an aluminum electrolytic cell lining waste cathode carbon block crushing device according to the present invention includes a support frame 2, a crushing assembly is arranged at the inner bottom of the support frame 2, and a hopper 1 is fixedly arranged on the upper part of the crushing assembly, and the hopper 1 Connected with the feeding device, the feeding device adopts the prior art, and the waste cathode carbon block can be transported to the hopper 1 through the feeding device, and the bottom side of the crushing assembly corresponds to the position of the discharge port 6, and the outlet The feed port 6 is fixedly arranged on the bottom side of the support frame 2, and the discharge port 6 is connected with the feeding device. The feeding device is a conveyor belt in the prior art, and the crushed waste cathode carbon blocks can be transported to the In the harmless treatment device for waste cathode carbon blocks, the crushing assem...

Embodiment 2

[0044] Such as Figure 9-10 As shown, on the basis of Embodiment 1, the difference between Embodiment 2 and Embodiment 1 is that: the feed inlet 903 is located near the edge of the upper mount 904, and the drop area is located on the lower mount On the upper surface of the seat 1002 close to the edge, the feed inlet 903 and the blanking area are located on the edge, which can better realize the crushing operation of the spent cathode carbon block, and help to improve the crushing effect and work efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com