Polytetrafluoroethylene film pulling winding device

A polytetrafluoroethylene, coiling device technology, applied in the direction of coiling strips, thin material handling, transportation and packaging, etc., can solve the problems of film loosening, film overlapping, quality problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

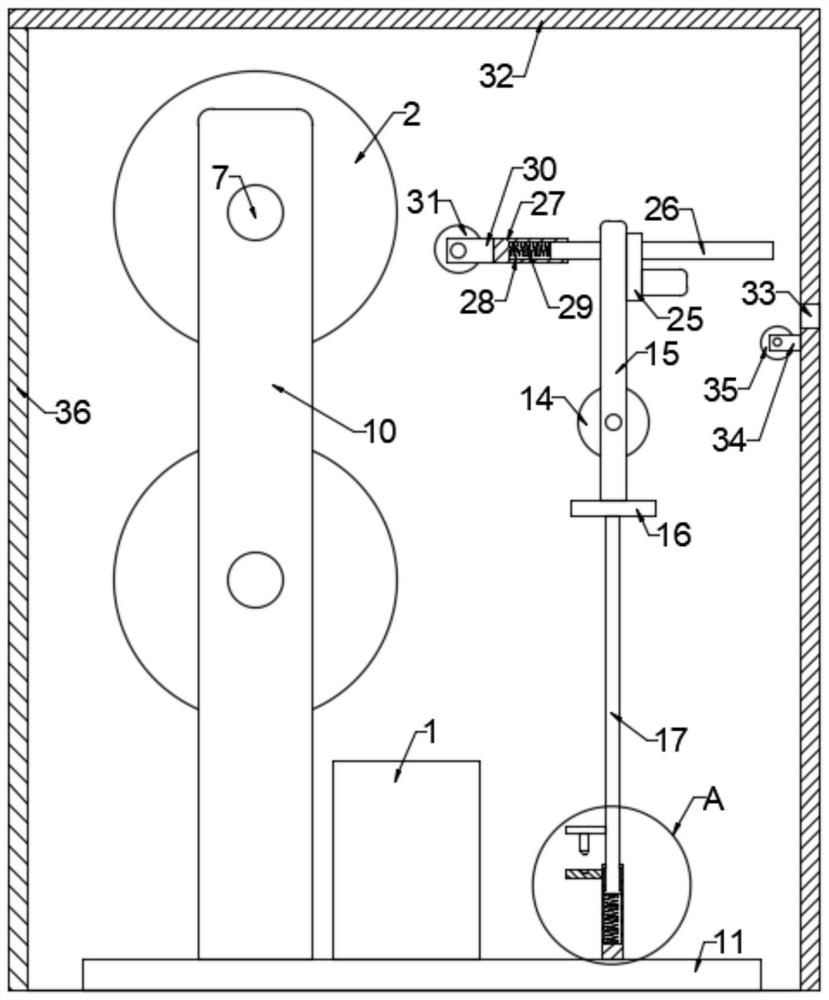

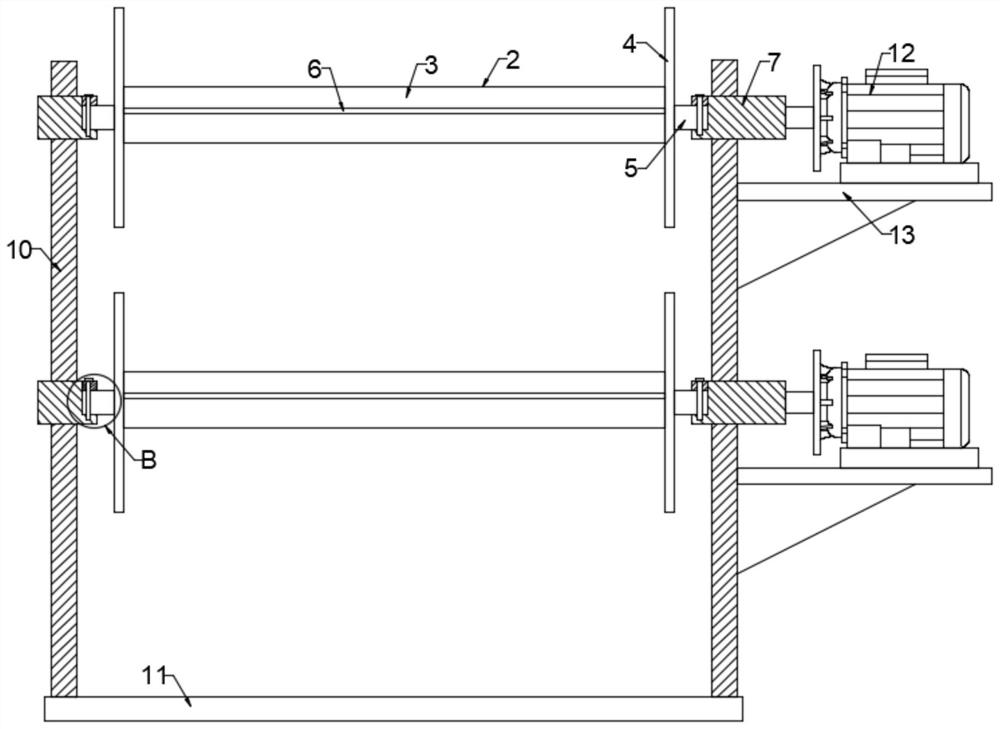

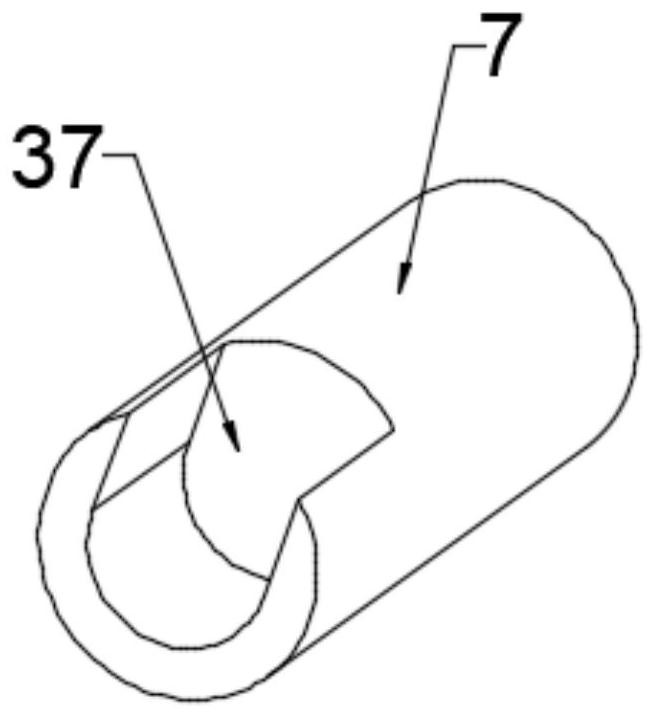

[0027] see Figure 1-5 , a polytetrafluoroethylene film traction and winding device, including a base plate 11, a support plate 10 arranged on the base plate 11, and a take-up roller 2 installed on the support plate 10, the front side of the take-up roller 2 is provided with a guide Assemblies, the guide assembly is fixedly connected with a first slide bar 17, the first slide bar 17 is slidably connected with a first slide sleeve 18 fixedly connected with the bottom plate 11, the first slide sleeve 18 is provided with a The first chute 20, the first elastic member 19 is arranged between the bottom wall of the first chute 20 and the first slide bar 17, the first elastic member 19 is a spring, and the first slide bar 17 is fixedly connected with a first A fixed plate 21, the first fixed plate 21 is fixedly connected with the nesting rod 22, the head of the nesting rod 22 is conical and is fixedly connected with the first electromagnetic block 38, the first electromagnetic block ...

Embodiment 2

[0034] This embodiment is expanded on the basis of Embodiment 1. The outer side of the bottom plate 11 is covered with a protective shell 32. The protective shell 32 is provided with a through groove 33 for the film to enter and exit. The protective shell 32 is located on the rear side of the take-up roller 2. The opening and closing door 36 that can be opened and closed can avoid the disturbance of dust during the film winding process by setting the protective shell 32, and keep it clean and hygienic. By opening the opening and closing door 36, the coiled film can be manually removed. Roller 2, described protective case 32 is fixedly connected with the 3rd support 34 that is positioned at the lower end of channel 33, and the 3rd support 34 is installed with the 2nd guide roller 35, further guides film by the 2nd guide roller 35, avoids and passes through The sharp edges of the groove 33 are in contact, affecting the film quality.

[0035] Working principle of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com