Vacuum suction and discharge machine and method of use thereof

A vacuum suction and vacuum technology, which is applied to the removal of liquid/gas/vapor by suction, textiles and papermaking, etc. It can solve the problems of stiff hand feeling, difficulty in restoring thickness, and increased production costs, so as to avoid stiff hand feel and thickness loss, avoiding the effect of rigid extrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

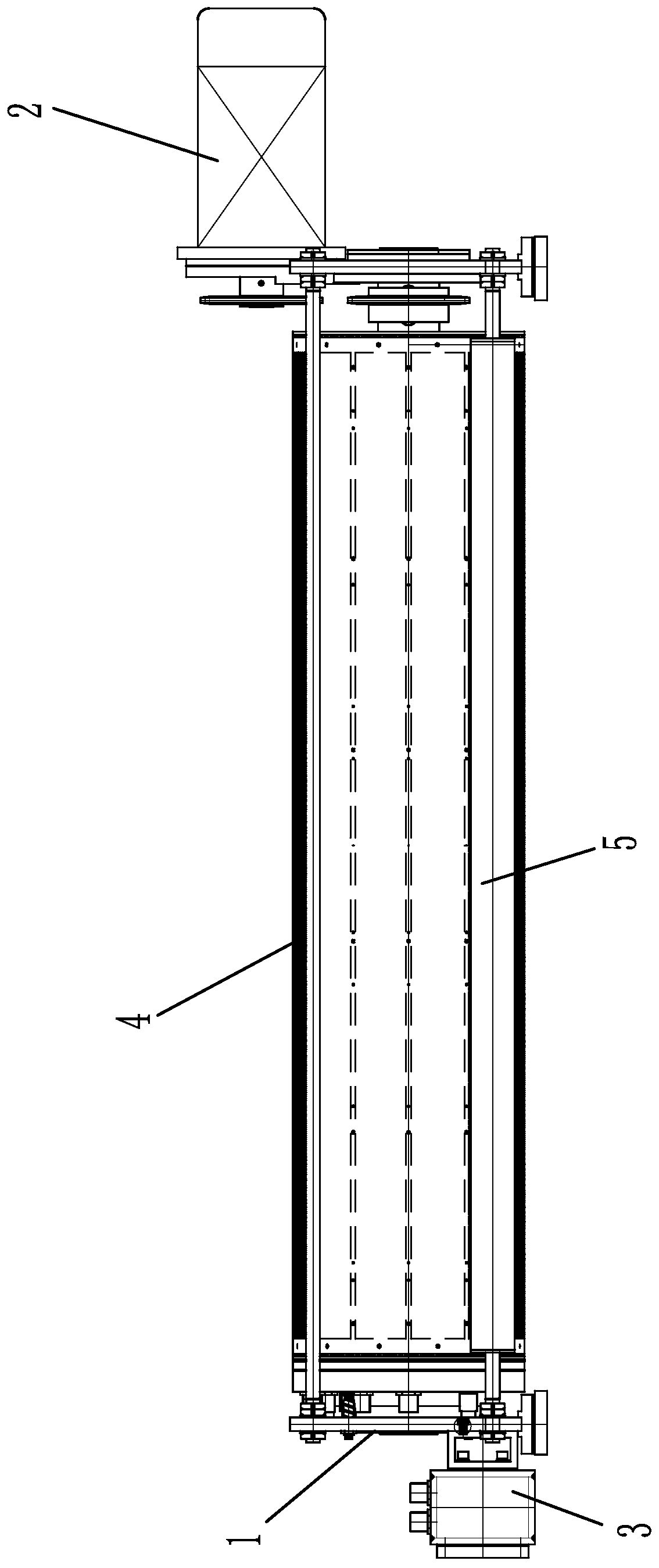

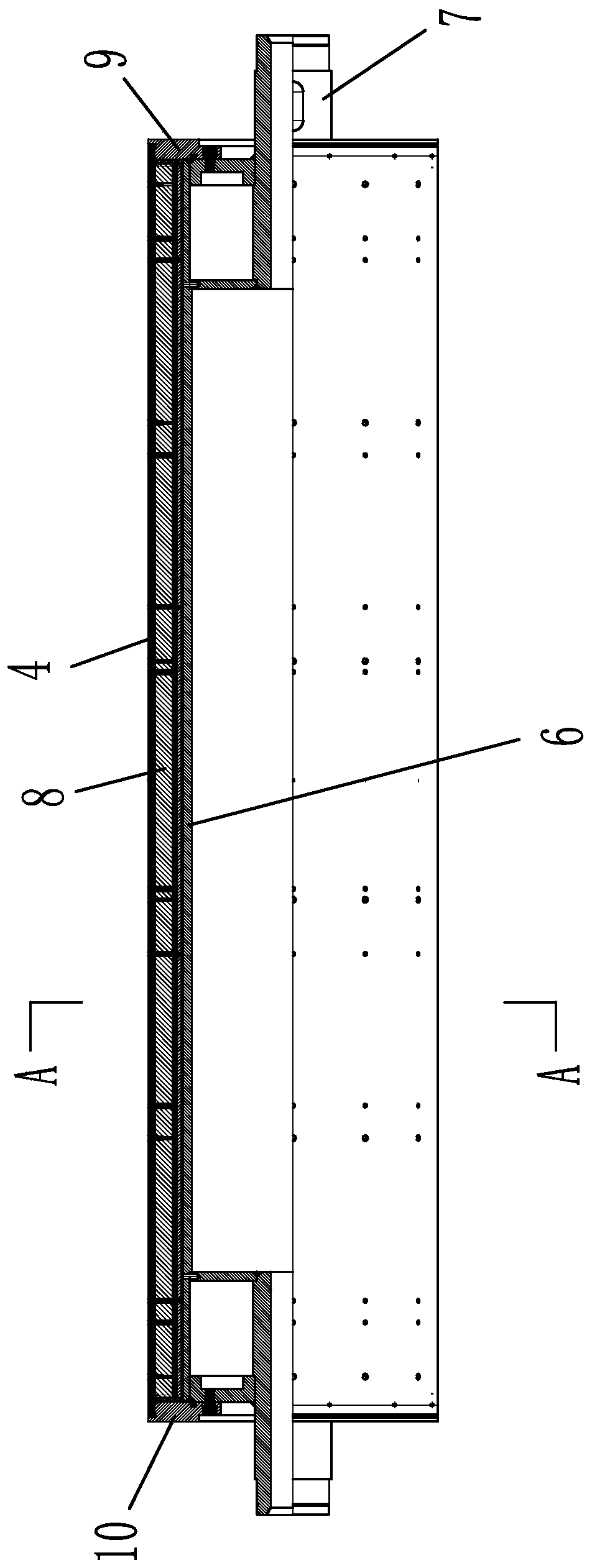

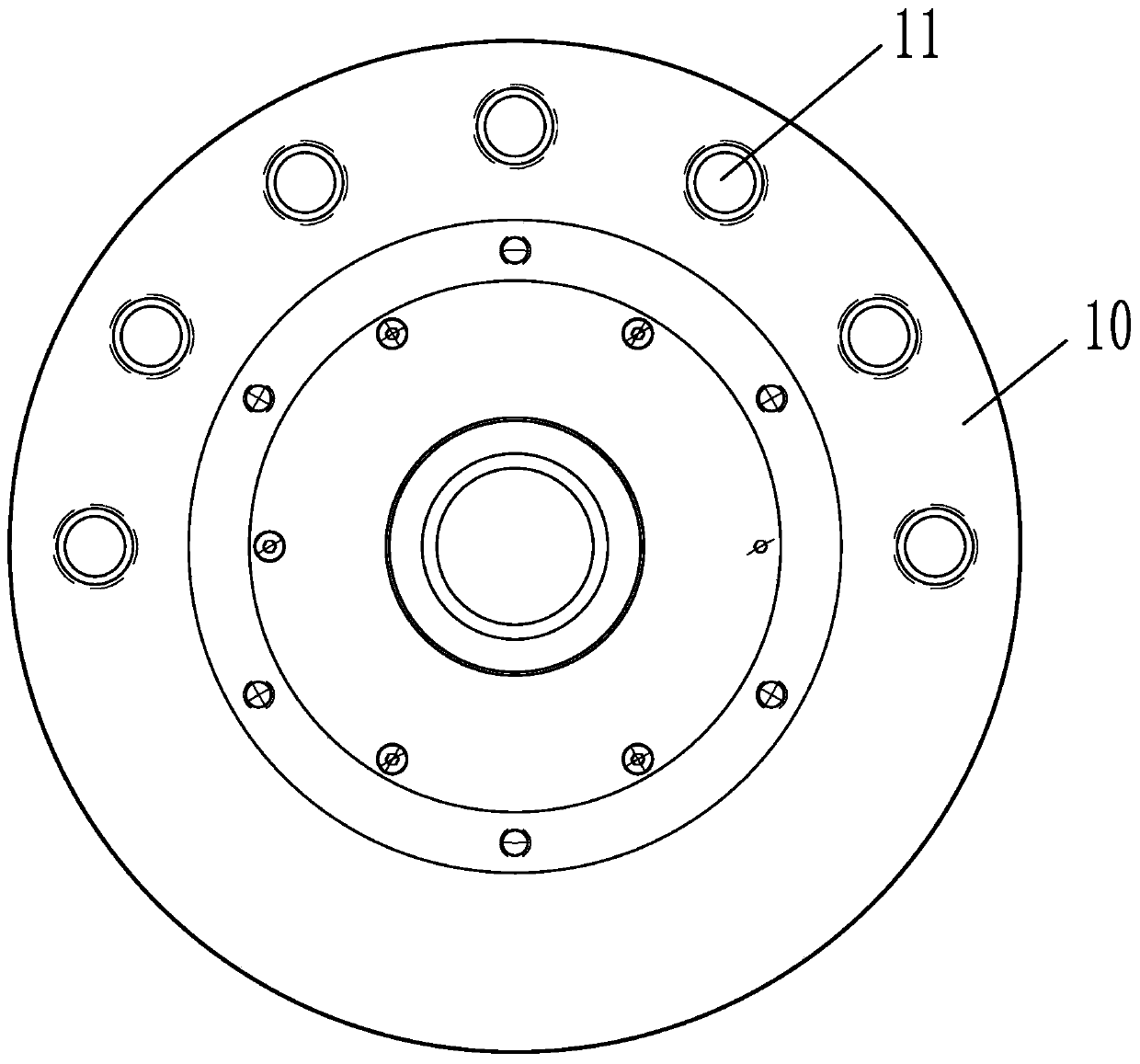

[0024] Embodiment 1: as figure 1 , 2 , 3, 4, and 5, a vacuum suction and discharge machine includes a frame 1, a drive motor 2 and a vacuum pump 3, and a positioning cylinder 6 is arranged horizontally on the upper level. The outside of the positioning cylinder is connected with a vacuum cylinder 4 through a vacuum connection assembly, and the positioning One end of the cylinder is provided with a sealing plate 9 connected with the vacuum connection assembly and one end of the vacuum cylinder, and the other end of the positioning cylinder is provided with a vacuum positioning disk 10 connected with the vacuum connection assembly, and the positioning cylinder is connected to the vacuum through the vacuum connection plate. The assembly is connected to the other end of the vacuum cylinder, and the axis of both ends of the positioning cylinder is provided with a mandrel 7, the mandrel at one end penetrates the sealing disc and connects with the drive motor, and the mandrel at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com