Process for preparing lithium bis (trimethyldisilyl) amide

A technology of bistrimethyldisilazylamino and hexamethyldisilazane, which is applied in the field of preparing bistrimethyldisilazide lithium, can solve the problems of crystal precipitation, low solubility, difficult recovery, etc., and improve the Utilization rate, equipment investment savings, and the effect of improving competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018]A lot of specific details are set forth in the following description to fully understand the present invention, but the present invention may also employ other different embodiments thereof, and therefore, the present invention is not limited to the specific embodiments disclosed below. limit.

[0019]After the process conditions, after the start of the raw material preparation, the reactor system cooling system is installed, the inert gas pipeline is installed, and the equipment is cleaned dry, and the basic preparation of personnel training is completed.

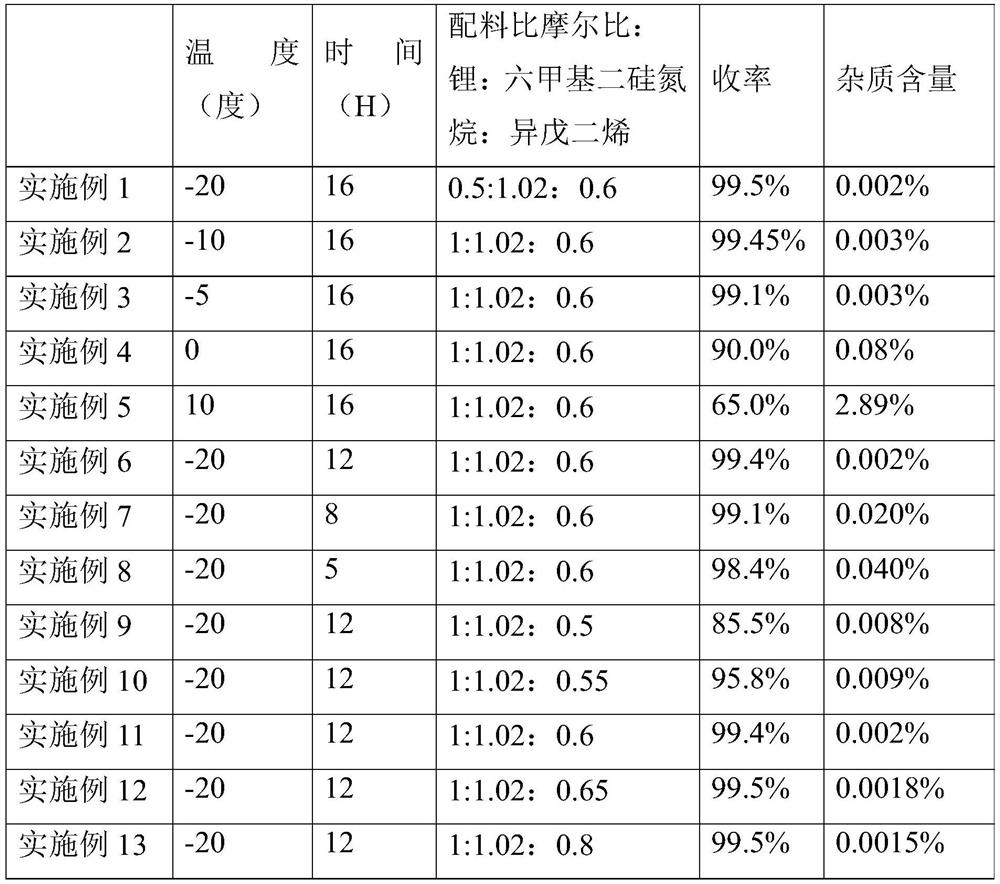

[0020]The present invention is obtained by one-step synthesis of reaction with lithium, isoprene, hexamethyldisodisiline, tetrahydrofuran as a raw material, and the finished product is obtained. The specific parameters in each embodiment are as follows:

[0021]

[0022]By comparing the above embodiment, the final selection process condition is between the temperature -20 to -10, the reaction time is 12-16 hours, the ingredient ratio ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap