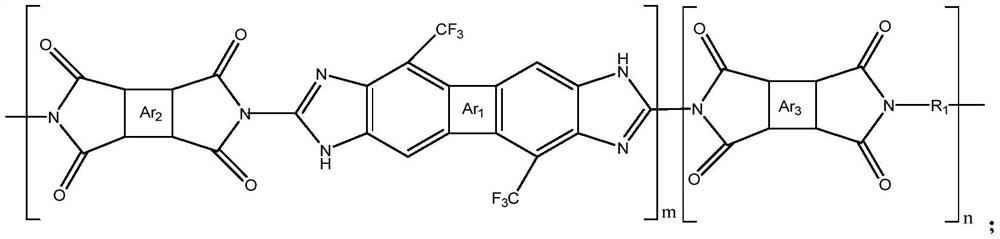

Highly transparent and low-expansion polyimide film containing benzimidazole structure and preparation method thereof

A technology of polyimide film and benzimidazole, which is applied in the field of high-transparency and low-expansion polyimide film and its preparation, can solve the problems of unresearched light transmittance, thermoplastic low thermal expansion coefficient, etc., and promote localization Development, low heat resistance, low thermal expansion coefficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

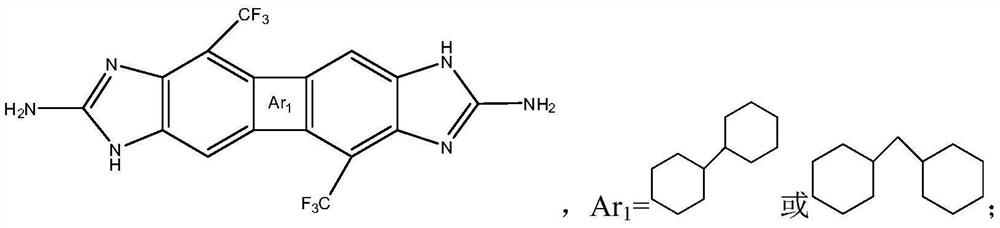

Method used

Image

Examples

Embodiment 1

[0038] Prepare high transparency and low expansion polyimide film according to the following method:

[0039](1) Under the protection of nitrogen, add 4.84g of benzimidazole diamine monomer HBP-BI and 42.49g of DMAc into a four-necked flask. After completely dissolving, add 4.4868g of dianhydride monomer 6FDA in batches. Stirring at 35° C. for 8 hours to obtain a polyamic acid solution through polycondensation reaction;

[0040] (2) Add catalyst triethylamine 4.5536g and dehydrating agent acetic anhydride 4.5941g to the above polyamic acid solution for chemical imidization, stir at 40°C for 8h to obtain a polyimide solution;

[0041] (3) The obtained polyimide solution was cast on ultra-flat glass, and then dried in an oven at 120° C. for 24 hours to obtain a highly transparent and low-expansion polyimide film.

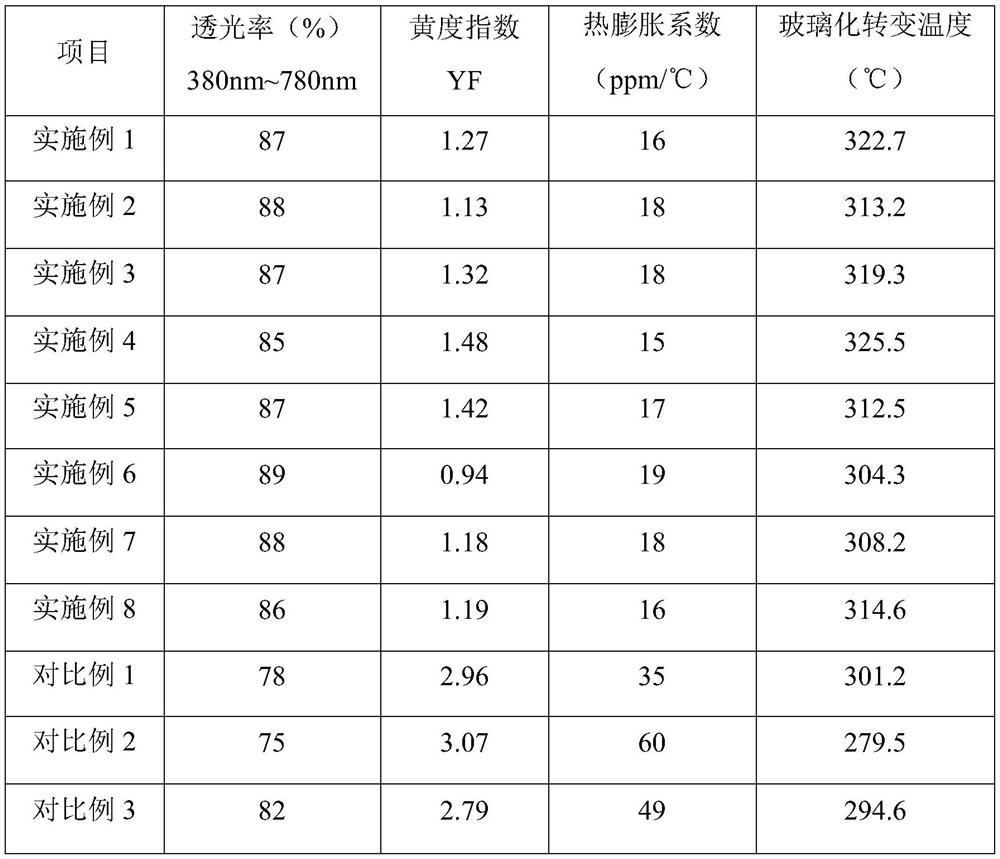

[0042] (4) The properties of the obtained polyimide film were characterized. The light transmittance at 380nm-780nm was 87%, the yellowness index was 1.27, the therm...

Embodiment 2

[0044] Prepare high transparency and low expansion polyimide film according to the following method:

[0045] (1) Under the protection of nitrogen, add 2.42g of benzimidazole diamine monomer HBP-BI, 1.6012g of TFMB (the ratio of HBP-BI and TFMB is 1:1) and 38.76g of DMAc into a four-necked flask, and after completely dissolving , add 4.4868g dianhydride monomer 6FDA in batches, stir at 35°C for 8h, and obtain polyamic acid solution through polycondensation reaction;

[0046] (2) Add catalyst triethylamine 4.5536g and dehydrating agent acetic anhydride 4.5941g to the above polyamic acid solution for chemical imidization, stir at 40°C for 8h to obtain a polyimide solution;

[0047] (3) The obtained polyimide solution was cast on ultra-flat glass, and then dried in an oven at 120° C. for 24 hours to obtain a highly transparent and low-expansion polyimide film.

[0048] (4) The properties of the obtained polyimide film were characterized. The light transmittance at 380nm-780nm wa...

Embodiment 3

[0050] Prepare high transparency and low expansion polyimide film according to the following method:

[0051] (1) Under the protection of nitrogen, add 3.872g of benzimidazole diamine monomer HBP-BI, 0.6405g of TFMB (the ratio of HBP-BI and TFMB is 8:2) and 38.76g of DMAc into a four-necked flask, and after completely dissolving , add 4.4868g dianhydride monomer 6FDA in batches, stir at 35°C for 8h, and obtain polyamic acid solution through polycondensation reaction;

[0052] (2) Add catalyst triethylamine 4.5536g and dehydrating agent acetic anhydride 4.5941g to the above polyamic acid solution for chemical imidization, stir at 40°C for 8h to obtain a polyimide solution;

[0053] (3) The obtained polyimide solution was cast on ultra-flat glass, and then dried in an oven at 120° C. for 24 hours to obtain a highly transparent and low-expansion polyimide film.

[0054] (4) The properties of the obtained polyimide film were characterized. The light transmittance at 380nm-780nm w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com