Equipment zero-point parameter adjusting method with weighing sensor and storage medium

A technology for parameter adjustment and equipment, applied in the detailed information of weighing equipment, weighing equipment testing/calibration, weighing equipment using elastically deformable parts, etc. , avoid parameter adjustment, the effect of high-precision measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

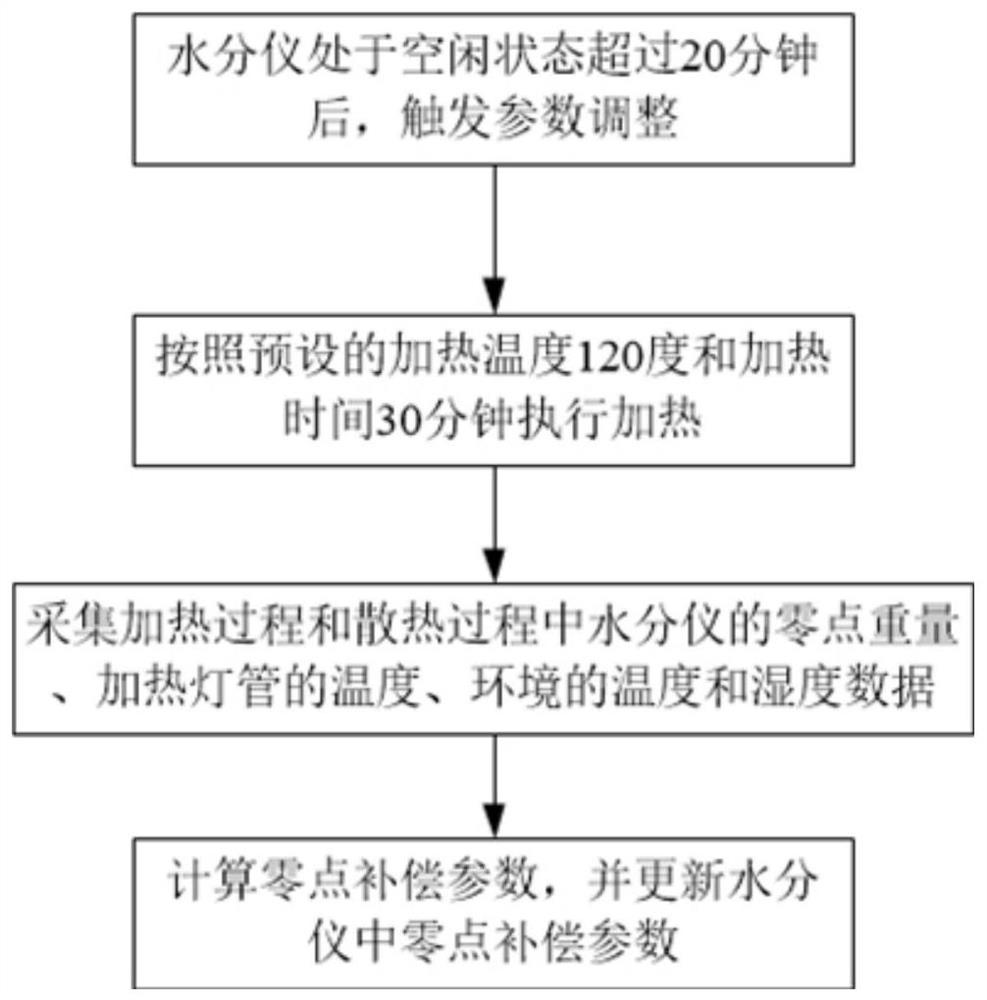

[0081] The zero point parameter adjustment method provided by the present invention and the application using the load cell in the device are online at the same time, and when the application of the load cell in the device is in an idle state, that is, when the application of the load cell does not perform tasks such as weighing, the analysis Changes in parameters that affect the zero point such as temperature adjust the zero point parameters of the load cell, so that the application performance of the load cell in the equipment will not be degraded due to changes in the environmental state, so the application accuracy of the load cell is improved.

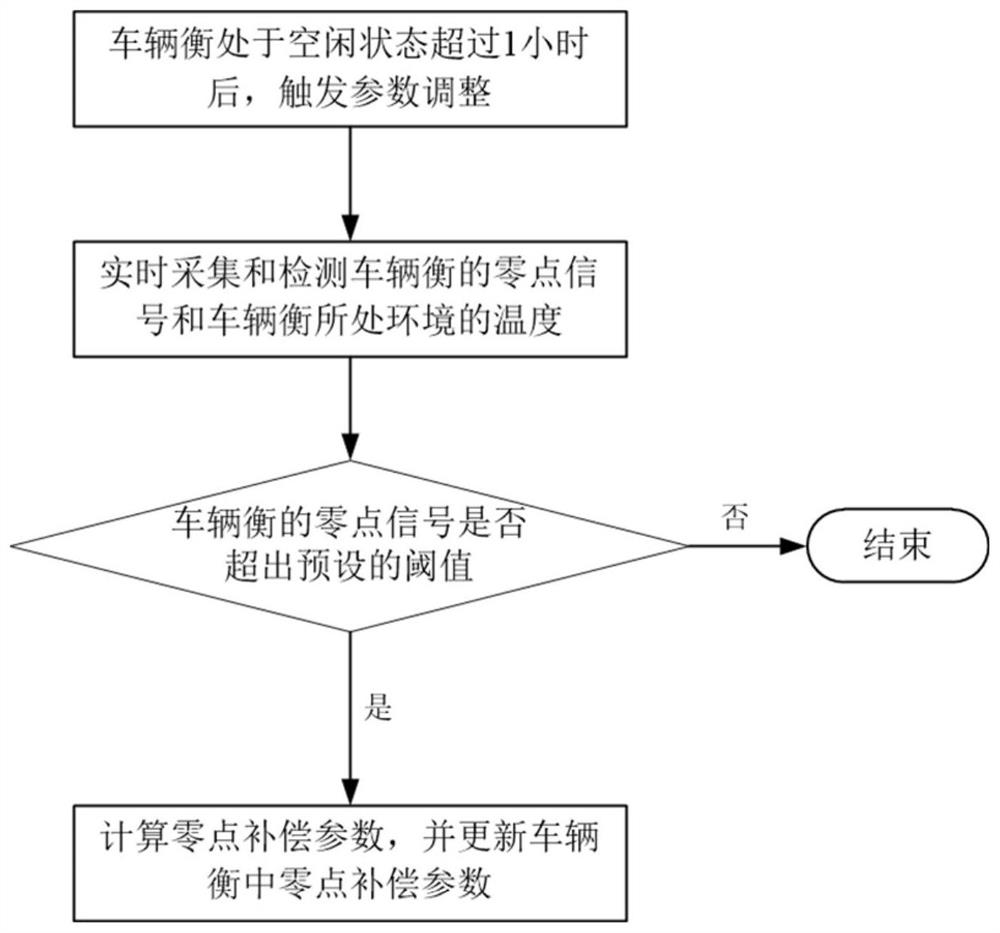

[0082] The zero-point parameter adjustment method and the weighing application in the vehicle scale are online at the same time, and the zero-point parameter adjustment is performe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com