Equipment for detecting ink explosion of paper

A technology of exploding ink and equipment, applied in the printing field, can solve problems such as differences in printing paper test results, lack of adjustment of equipment pressure, uneven mechanical force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

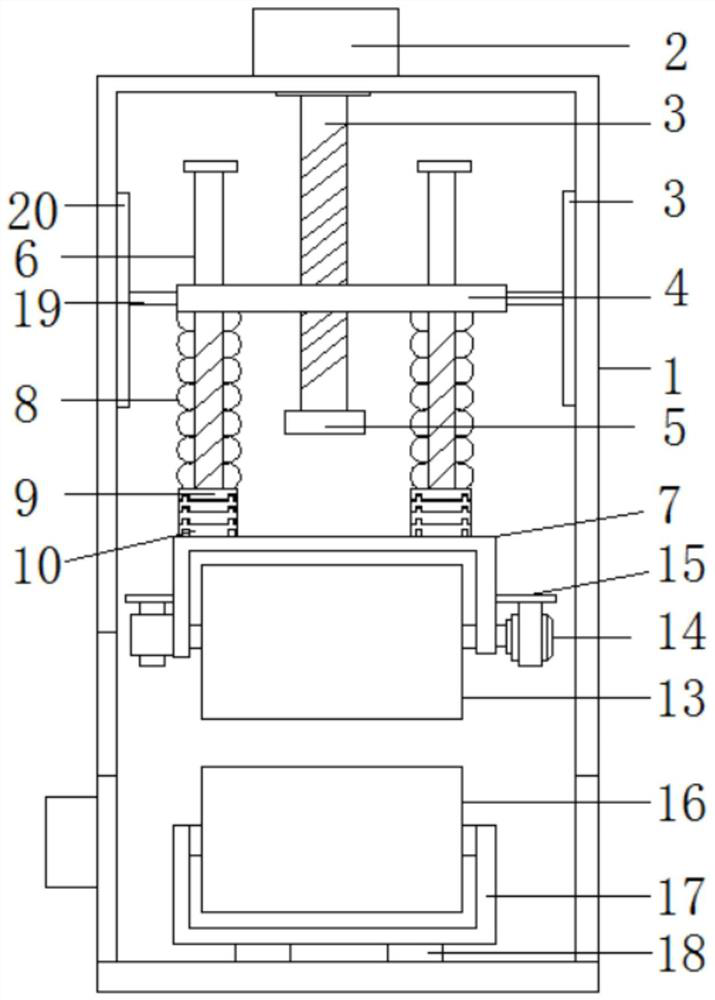

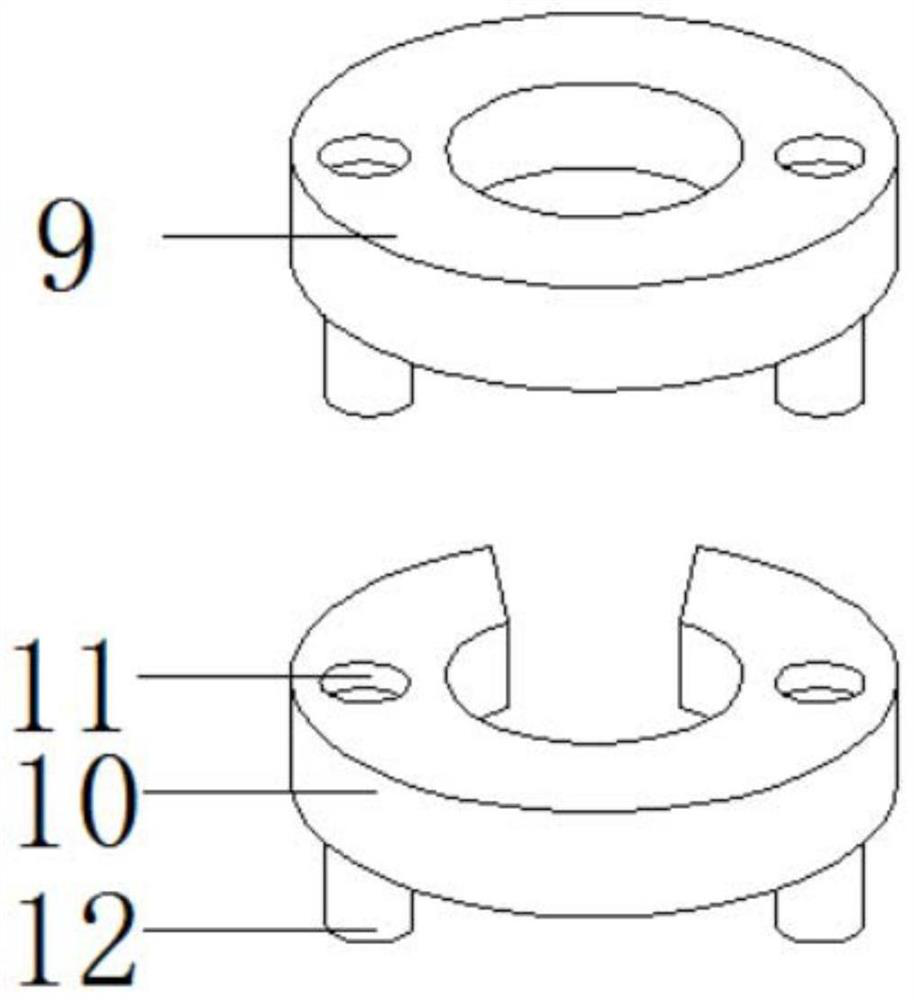

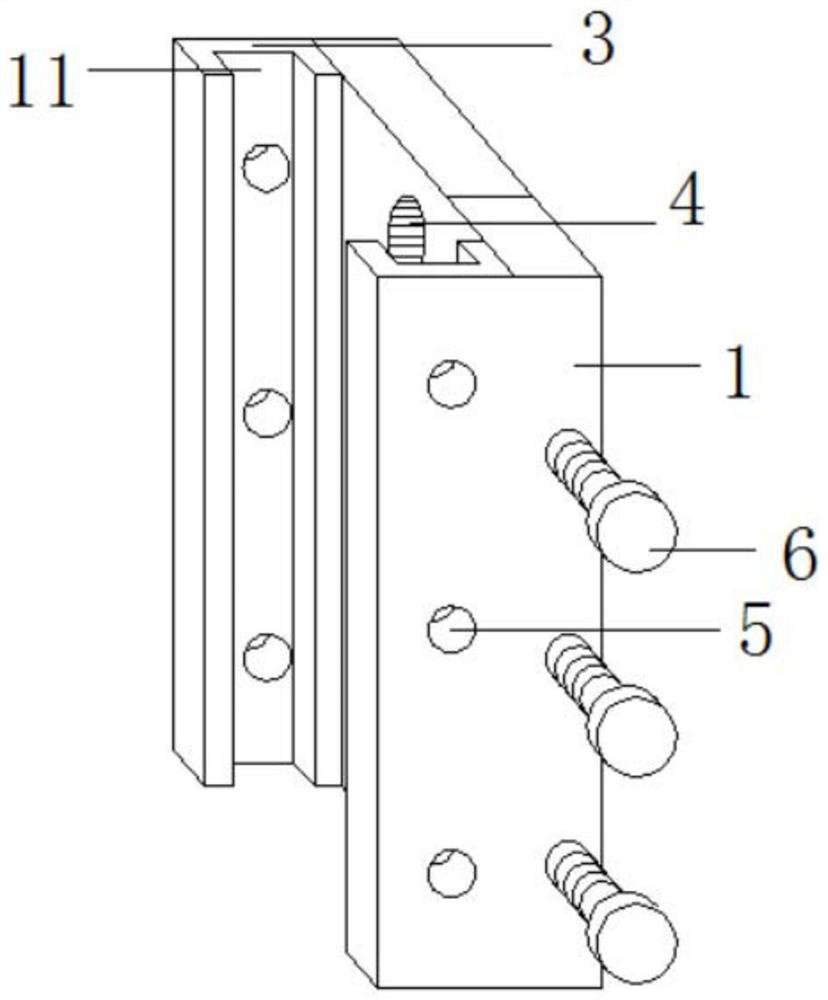

[0022] see Figure 1-2 , the present invention provides the following technical solutions: a device for detecting ink explosion on paper, including a detection chamber 1, a first motor 2 is fixedly connected to the top of the detection chamber 1, and the lower end of the first motor 2 penetrates to the detection chamber 1 through a screw rod 3 The inside is fixedly connected with the limit block 5, the upper end of the limit block 5 is located at the outer sliding connection of the screw rod 3, and the reciprocating plate 4 is connected, and the two ends of the reciprocating plate 4 are respectively penetrated with two movable rods 6, and the lower ends of the two movable rods 6 are fixed. Connected with drive chamber 7, one side of drive chamber 7 is fixedly connected with second motor 14 through mounting bracket 15, the output end of second motor 14 penetrates to the inside of drive chamber 7 and is connected with first roller 13 for rotation, and the outside of movable rod 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com