A connection device between drag chain and tire mold in latex production line

A production line and tire mold technology, which is applied in chain rings, chain elements, belts/chains/gears, etc., can solve problems such as difficulty in replacing failed parts, affecting service life, and high maintenance costs, and achieve simple structure, increased service life, and reduced The effect on production operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

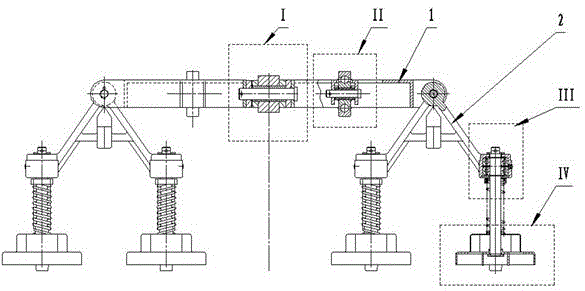

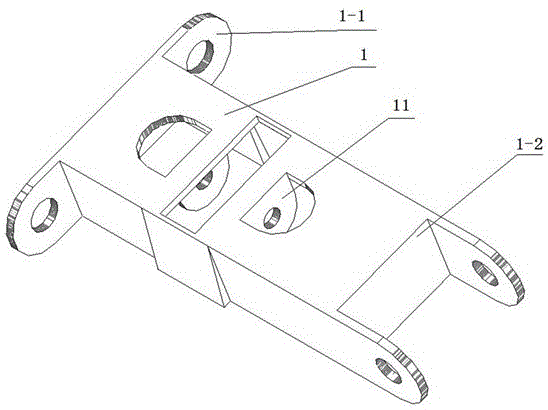

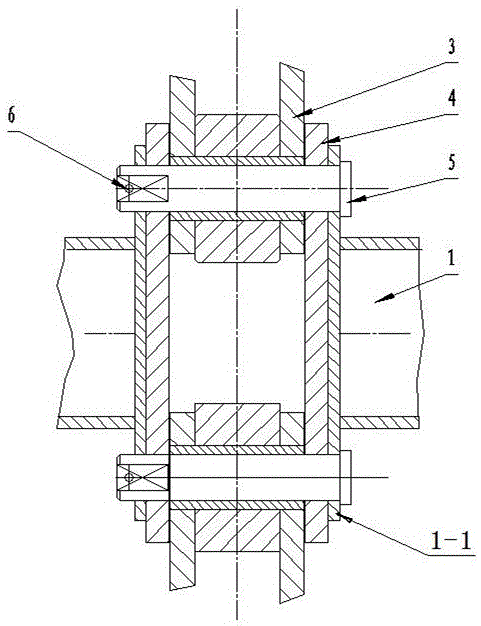

[0023] Such as figure 1 - Shown in 4, this device is made of production line drag chain I, auxiliary support bearing part II, bracket 1, movable yoke 2, movable yoke bearing chamber assembly III, rotating disc assembly IV. The bracket is an integral stamped part of metal sheet or welded after separate stamping, and it can also be a metal die-casting part or an engineering plastic injection-molded part. Bracket 1 is symmetrically arranged on both sides of production line drag chain 1, and can move in parallel with production line drag chain 1. Two movable forks 2 are arranged on the outer end of a bracket 1; the connection structure between the drag chain 1 of the production line and the bracket 1 is: each drag chain is provided with two inner chain plates 3 and outer chain plates 4, and the bracket 1 Connecting plate 1-1 is set at the inner end of the inner end, and inner chain plate 3, outer chain plate 4 and connecting plate 1-1 are connected by the drag chain pin 5 of wea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com