Stacking device of wood board stacking production line

A technology of a palletizing device and a production line is applied in the field of palletizing devices of a wood palletizing production line, which can solve the problems of low production efficiency, high labor intensity and high labor cost, and achieve the goal of improving production efficiency, reducing labor intensity and improving the scope of application. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

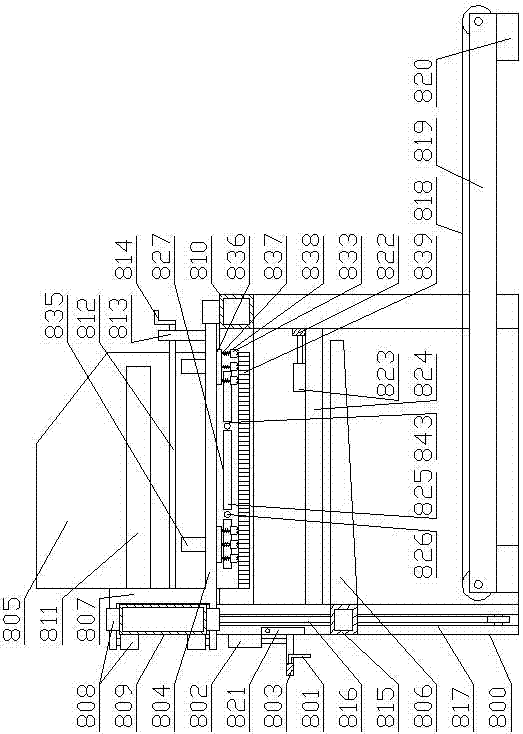

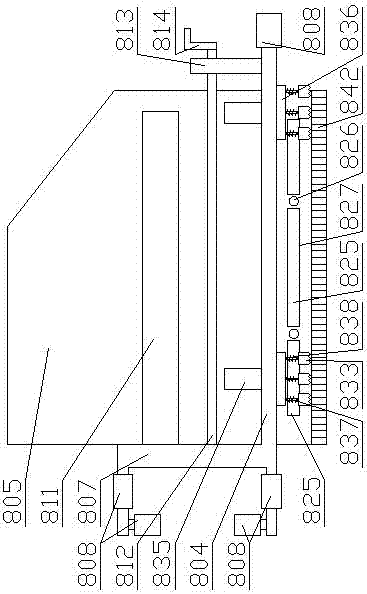

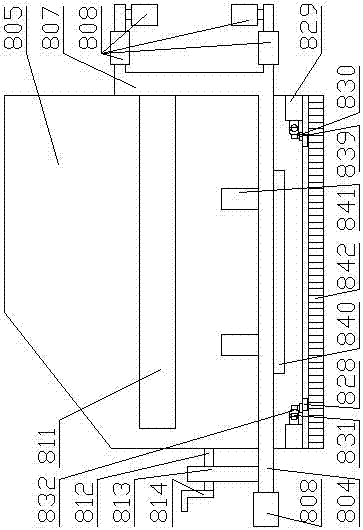

[0039] combine figure 1 , figure 2 and image 3 It can be seen that the present invention includes support columns 800 on four sides, and a row of spacer bar blanking devices are arranged horizontally on the top of the range enclosed by the support column 800. A row of palletizing support rods 806 is movably connected up and down below the device, and a row of palletizing and discharging conveyor chains 818 are arranged below the palletizing supporting rods 806. The vertical projection of the palletizing supporting rods 806 and the palletizing and discharging The vertical projections of the conveyor chains 818 are arranged at intervals. The palletizing discharge conveyor chain 818 protrudes from the palletizing discharge end, and the support column 800 is located on the side of the palletizing feed end and is movably connected with a row of feed gears up and down. Rod 801; the side of the stacking support bar 806 facing the stacking feed end is respectively fixed with the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com