Automatic copper wire stacking machine

A palletizer and automatic technology, applied in the direction of conveyor, conveyor objects, object stacking, etc., can solve the problems of high labor intensity and inconvenient operation of workers, reduce labor intensity, improve production efficiency, and improve code The effect of stacking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, the present invention will be further described.

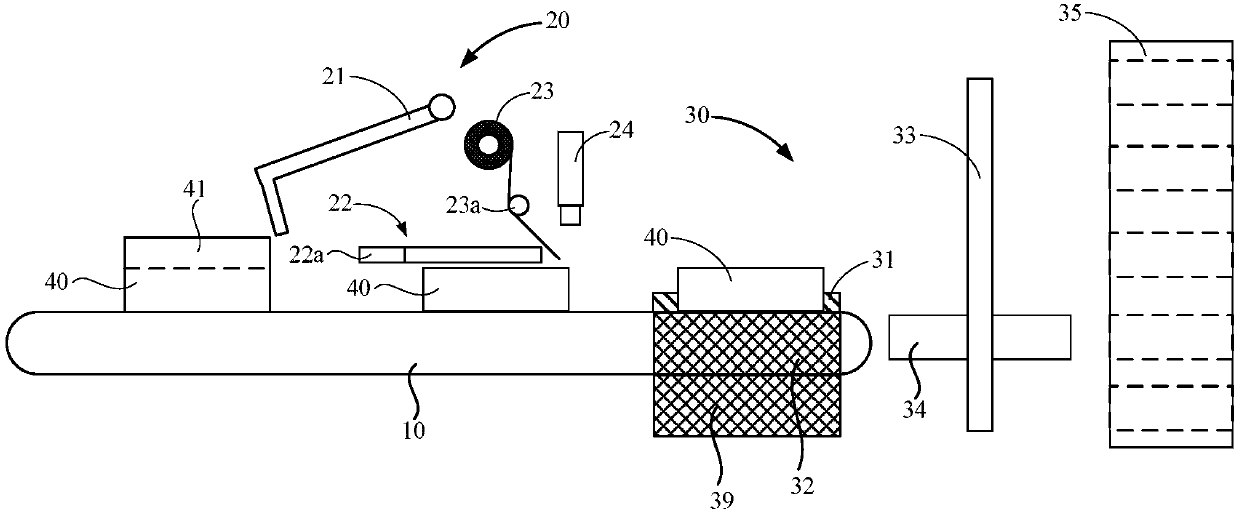

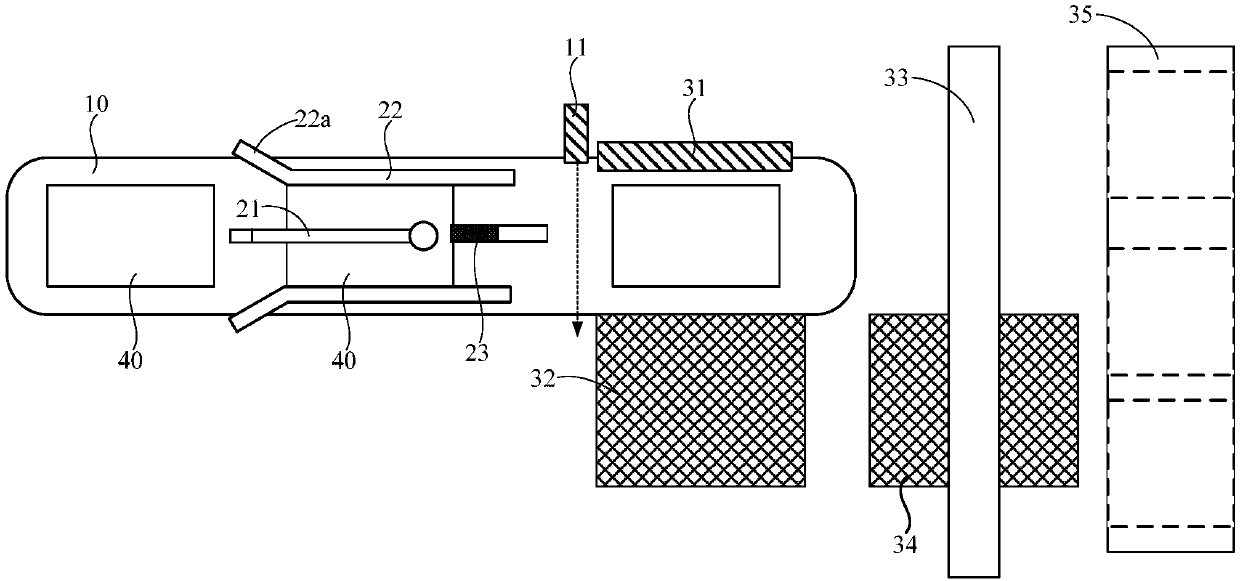

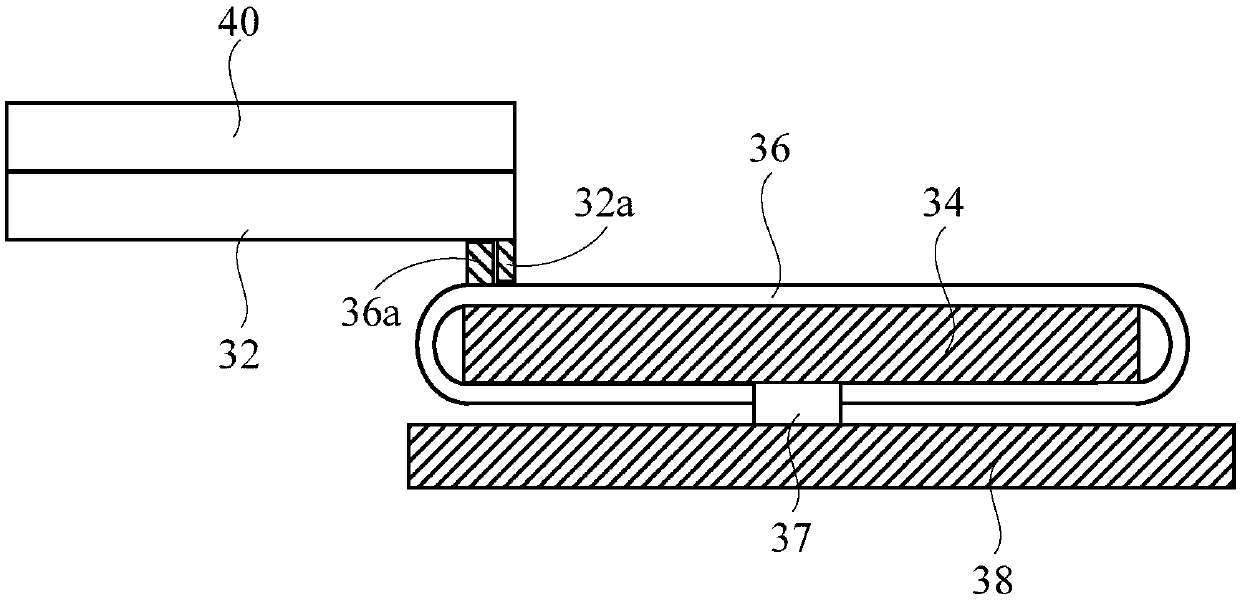

[0026] figure 1 It is a structural schematic diagram of an embodiment of the copper wire automatic palletizer provided by the present invention, figure 2 It is a structural schematic view of an embodiment of an automatic copper wire palletizer provided by the present invention in a top view state. Such as figure 1 and figure 2 As shown, the copper wire automatic palletizer includes a sealing mechanism 20 , a palletizing mechanism and a shelf 35 . The sealing mechanism 20 is used to attach the box page 41 of the packaging box 40 to the box opening, and seal the box opening of the packaging box 40 by tape, and the palletizing mechanism is used to stack the sealed packaging box 40 onto the shelf 35 .

[0027] The sealing mechanism 20 includes a conveyor belt 10 , a guide rod 22 and an adhesive tape module 23 . After the packaging box 40 is conveyed to the guide rod 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com