Batch recovery equipment for fuel cell catalyst slurry

A catalyst slurry, fuel cell technology, applied in battery electrodes, circuits, filter circuits, etc., can solve the problems of environmental pollution, loss of efficiency, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

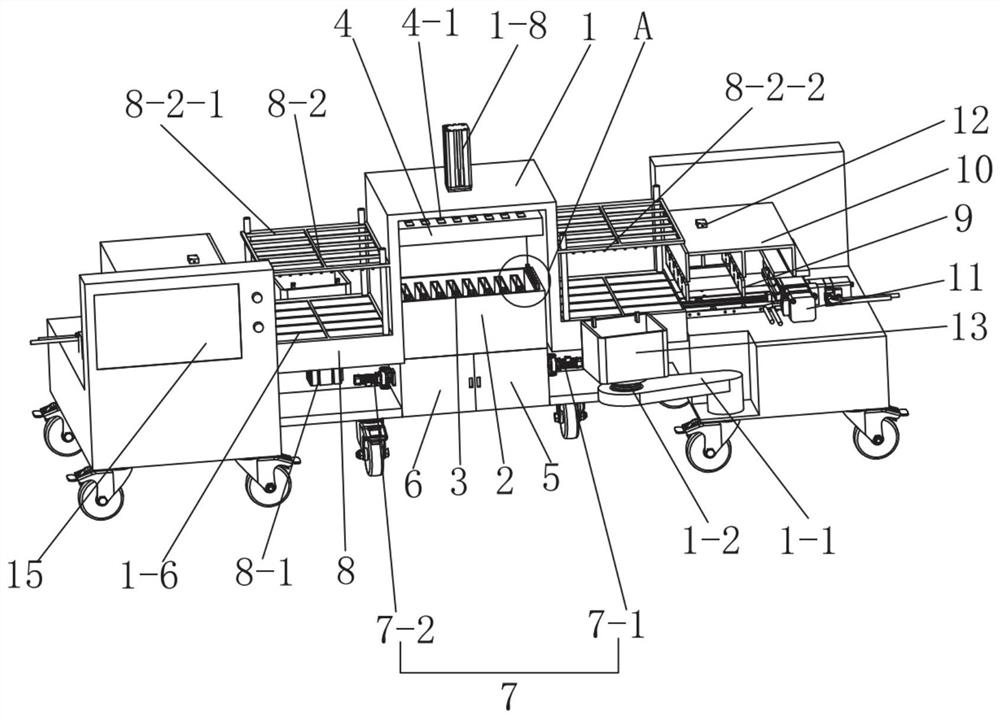

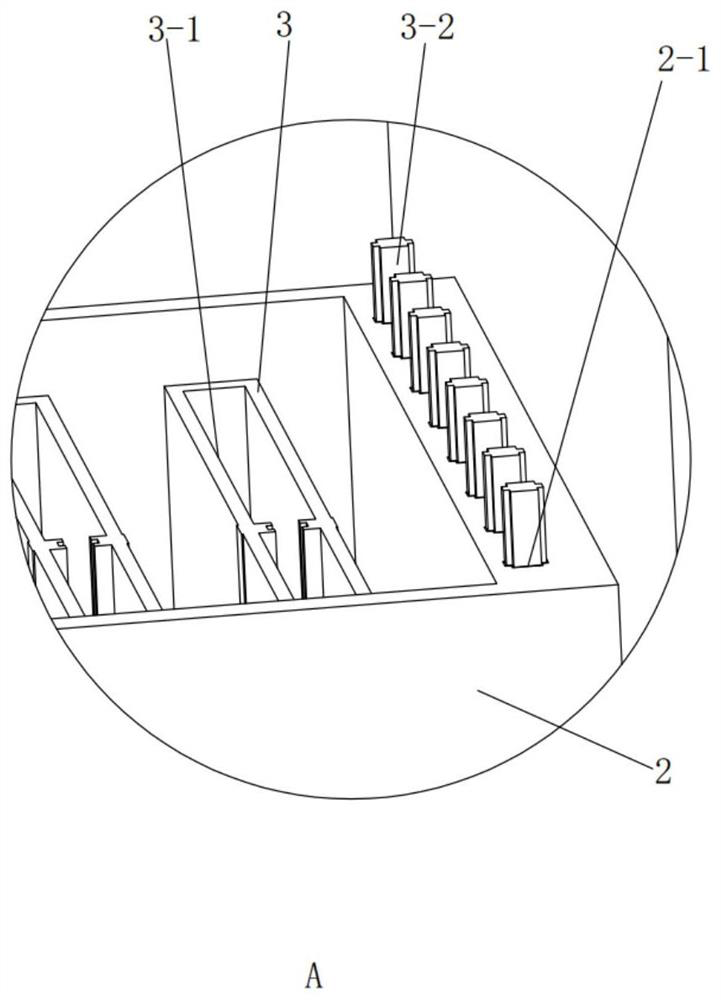

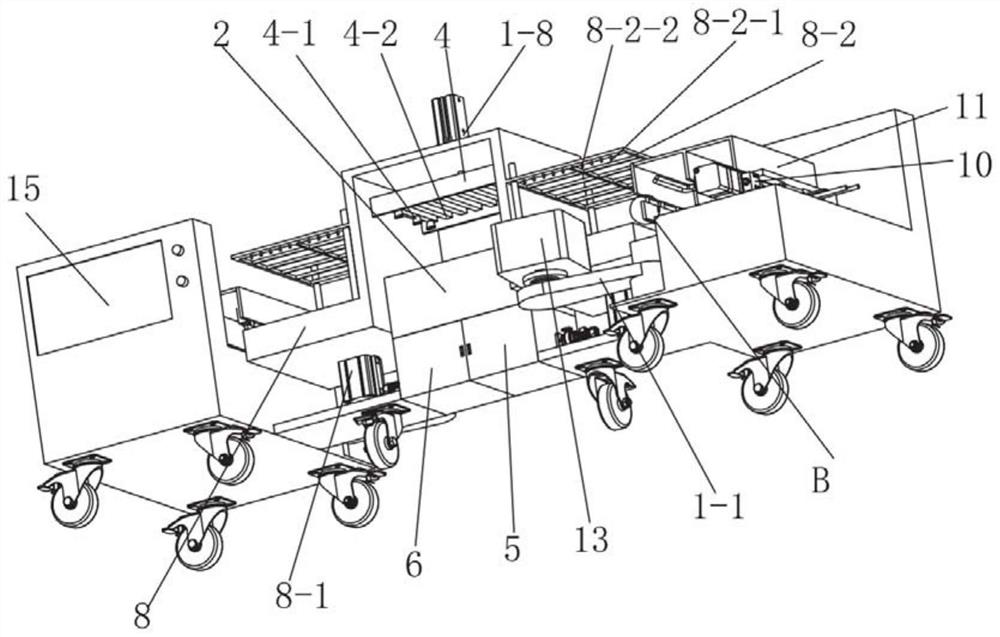

[0053] A fuel cell catalyst slurry batch recovery equipment, such as figure 1 Or shown in 3, comprise frame body 1, be provided with impregnation box 2 on frame body 1, be provided with the cover body 4 that impregnation box 2 is closed by sliding on frame body 1 simultaneously, and the work of controlling cover body 4 lifting Cylinders 1-8; eg figure 1 with 2 As shown, the impregnation box 2 is provided with a plurality of detachable plastic partitions 3 along its lengthwise array. The plastic partitions 3 can be installed in the dipping box 2 through structures such as clamps or limit grooves. Each plastic partition 3 are provided with a cavity 3-1 for storage of the carrier 16; in order to enhance the sealing performance of the carrier 16 when soaking in the cavity 3-1, the bottom array in the cover body 4 is provided with a plurality of sealing plugs 4-2, Such as image 3 As shown; when the cover body 4 descends under the action of the working cylinder 1-8 to realize th...

Embodiment approach

[0063] The specific implementation method adopts the catalyst slurry batch recovery method of this equipment as follows:

[0064] (1) Carrier 16 is covered on the surface of auxiliary equipment such as fixtures, and for the folding surface of auxiliary equipment, the mode that adopts multi-piece carrier 16 to connect in pairs extends to the folding corner of auxiliary equipment such as fixtures and wraps, and carrier 16 joints Use high temperature resistant tape 17 with a width of 3mm for bonding, such as Figure 8 As shown; avoid directly using a single large-area carrier 16 to fold and wrap, so as to reduce the folding area of the carrier 16 while covering the auxiliary equipment, ensure the overall flatness of each piece of carrier 16, and can be adjusted according to the shape and size of the auxiliary equipment. The carrier 16 takes shape.

[0065] Afterwards, during the preparation process of the membrane electrode, except for the effective catalyst slurry sprayed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com