Quick release push rod with high transmission efficiency

A transmission efficiency and fast technology, applied in the direction of electric components, mechanical energy control, electrical components, etc., can solve the problems of torsion spring wear of the clutch sleeve or gear assembly, inconvenient retraction of the push rod, etc., to reduce energy consumption and improve use The effect of life and reducing the degree of wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

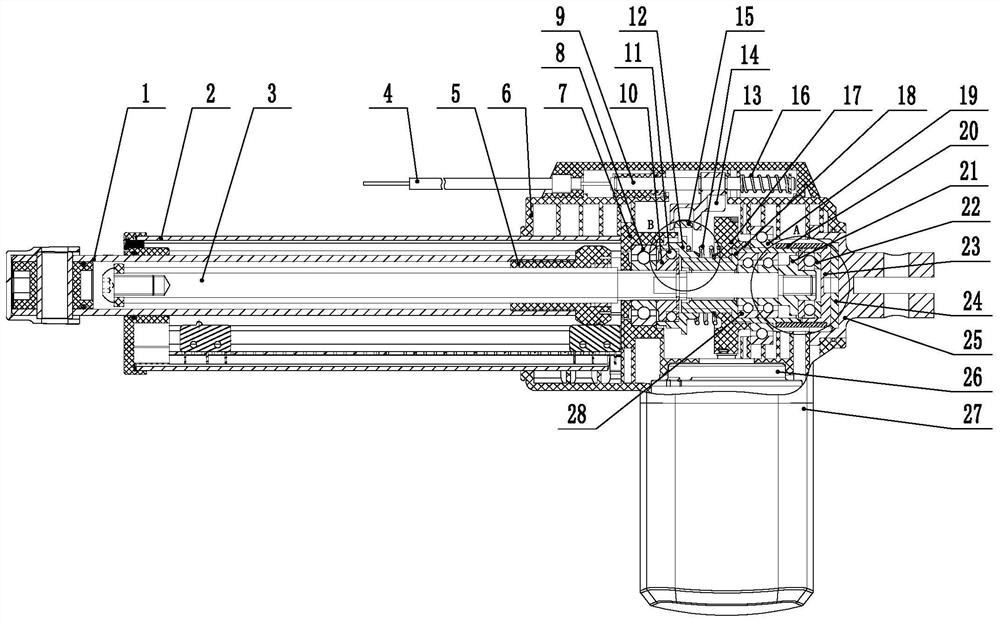

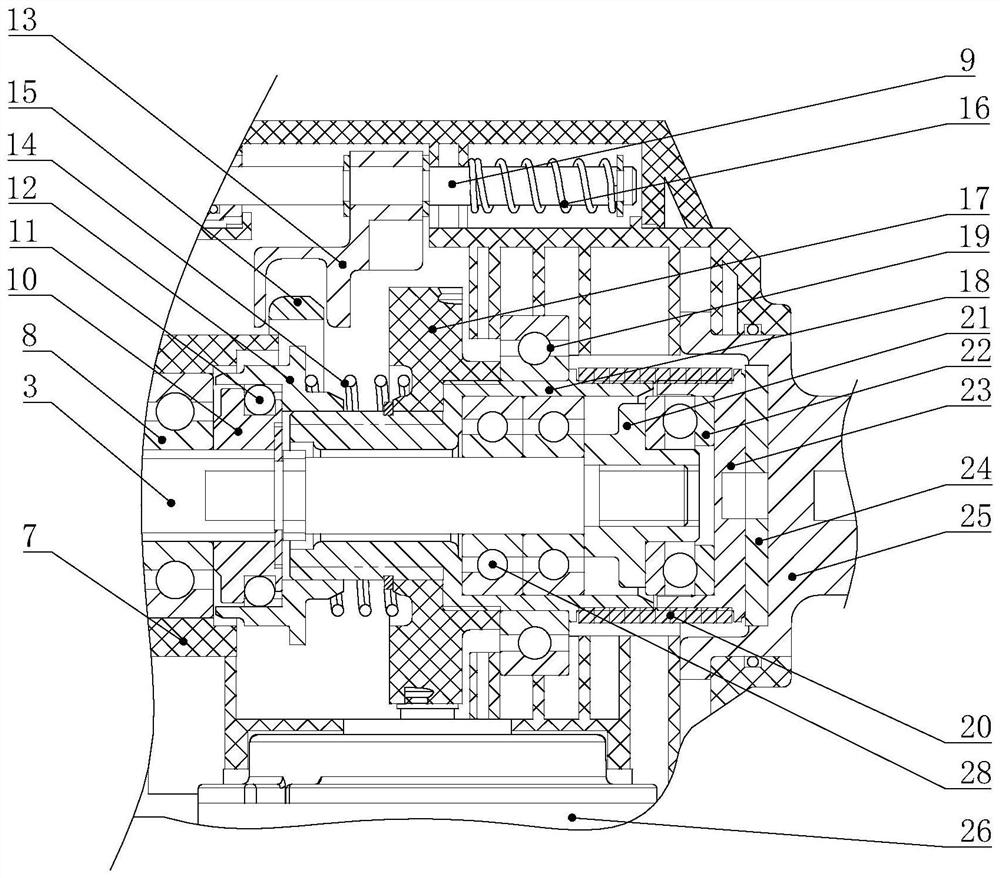

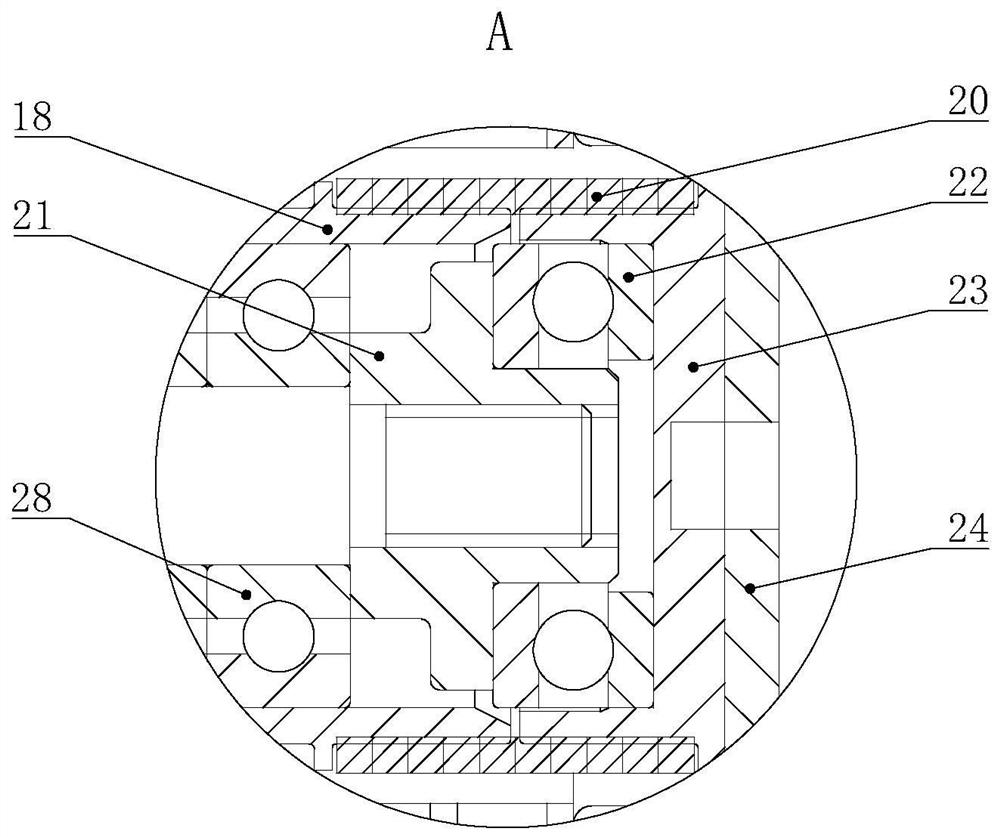

[0032] Such as Figure 1 to Figure 6 As shown, the preferred structure of the quick release push rod with high transmission efficiency in this embodiment includes a gearbox 6, a worm gear 17, a left connecting piece 10, a right connecting piece, a clutch sleeve 12 and a screw mandrel 3, and the left connecting piece 10 is connected to the The screw rod 3 is connected, the right connecting piece is relatively fixed to the worm wheel 17, the clutch sleeve 12 and the right connecting piece keep moving relative to each other in the axial direction and relatively fixed in the circumferential direction, and the clutch sleeve 12 moves axially to Combined with or separated from the left connecting piece 10, the clutch sleeve 12 keeps moving relative to the axial direction and relatively fixed in the circumferential direction when combined with the left connecting piece 10, the gear box 6 is provided with a friction plate 24, the When the quick release push rod bears a static load, the...

Embodiment 2

[0051] The difference between this embodiment and Embodiment 1 is that in this embodiment, the screw rod 3 is nested in the connecting seat 18, and a rolling element is arranged in the connecting seat 18, and the surface of the screw rod 3 is in contact with the connecting seat 18. The above-mentioned rolling parts are rolled and fitted, wherein, the rolling parts can be balls, cylinders, cones and other rolling parts. In this implementation, the rolling parts are preferably balls. In this way, the screw mandrel 3 can contact the connecting seat 18 through the balls to realize mutual positioning, and can axially slide relative to the connecting seat 18 so that the axial force exerted by the load on it can be transmitted to the torsion spring seat 23, and this embodiment can also achieve the technical effect described in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com