Chamfering device for cubic boron nitride superhard cutter

A cubic boron nitride and chamfering device technology, which is applied in chemical instruments and methods, solid separation, filtration and screening, etc., can solve the problems of troublesome material collection process, low screening efficiency, and consumption of manpower and material resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

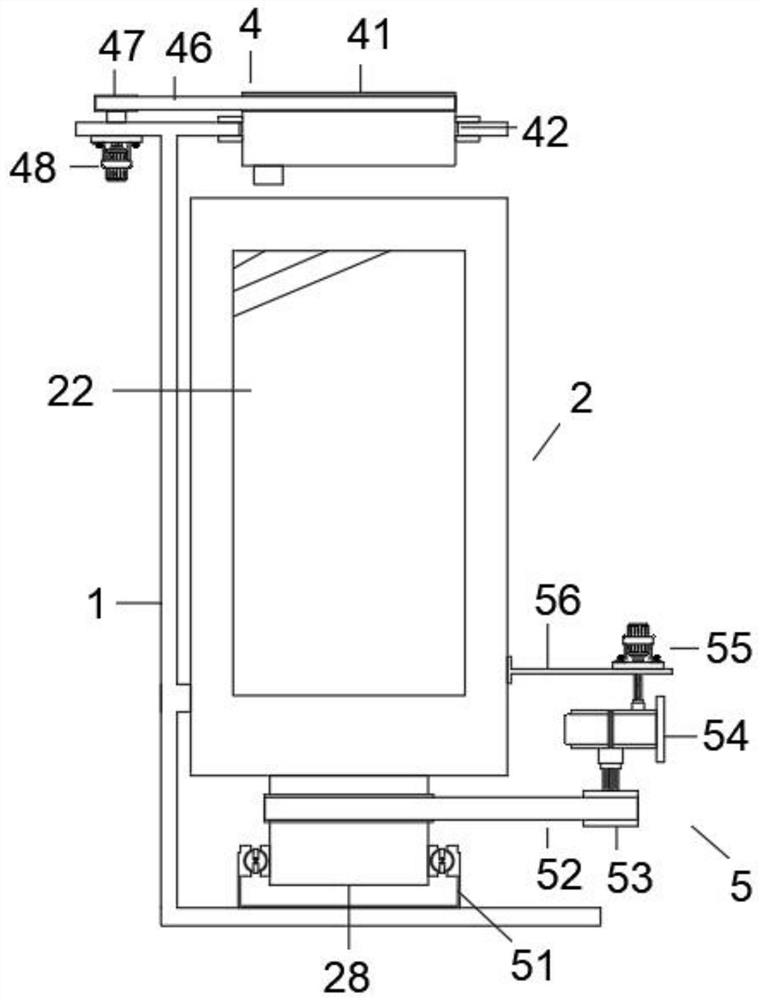

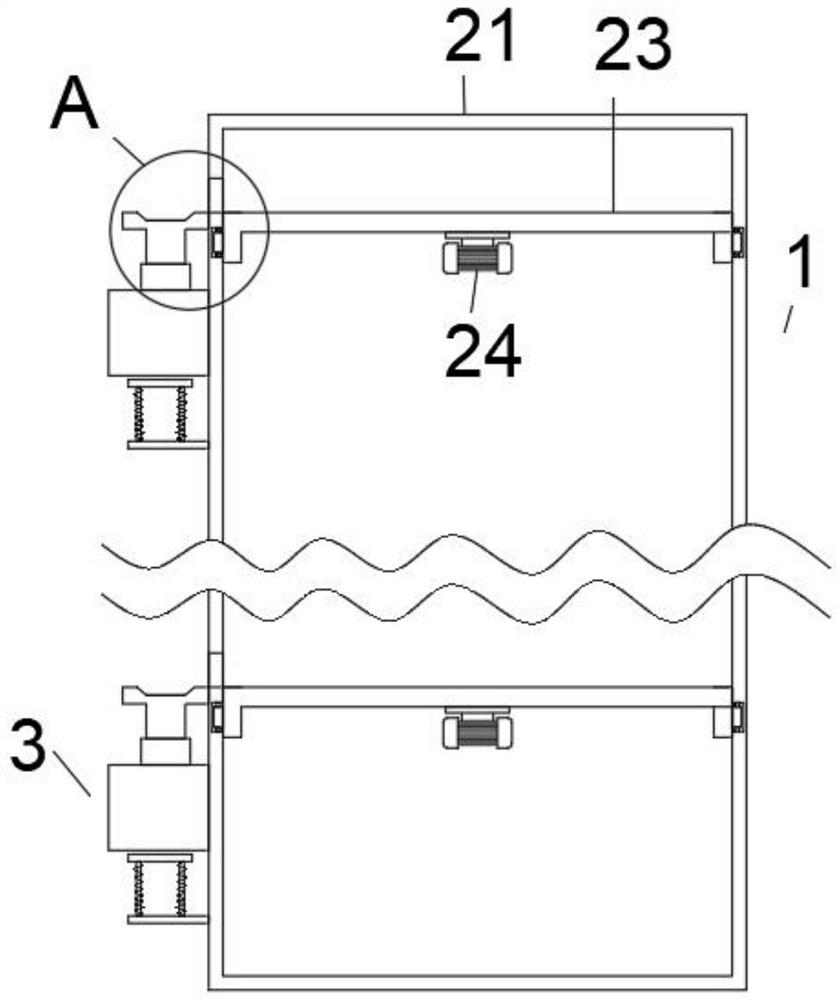

[0026] Such as Figure 1-5 As shown, this specific embodiment adopts the following technical solutions: a cubic boron nitride superhard tool chamfering device, including a bracket 1, the inner wall of the bracket 1 is provided with a screening mechanism 2, and the screening mechanism 2 is provided with There is a material receiving mechanism 3, and the bracket 1 above the screening mechanism 2 is provided with a feeding mechanism 4, and the bottom of the screening mechanism 2 is connected to the auxiliary mechanism 5 through transmission;

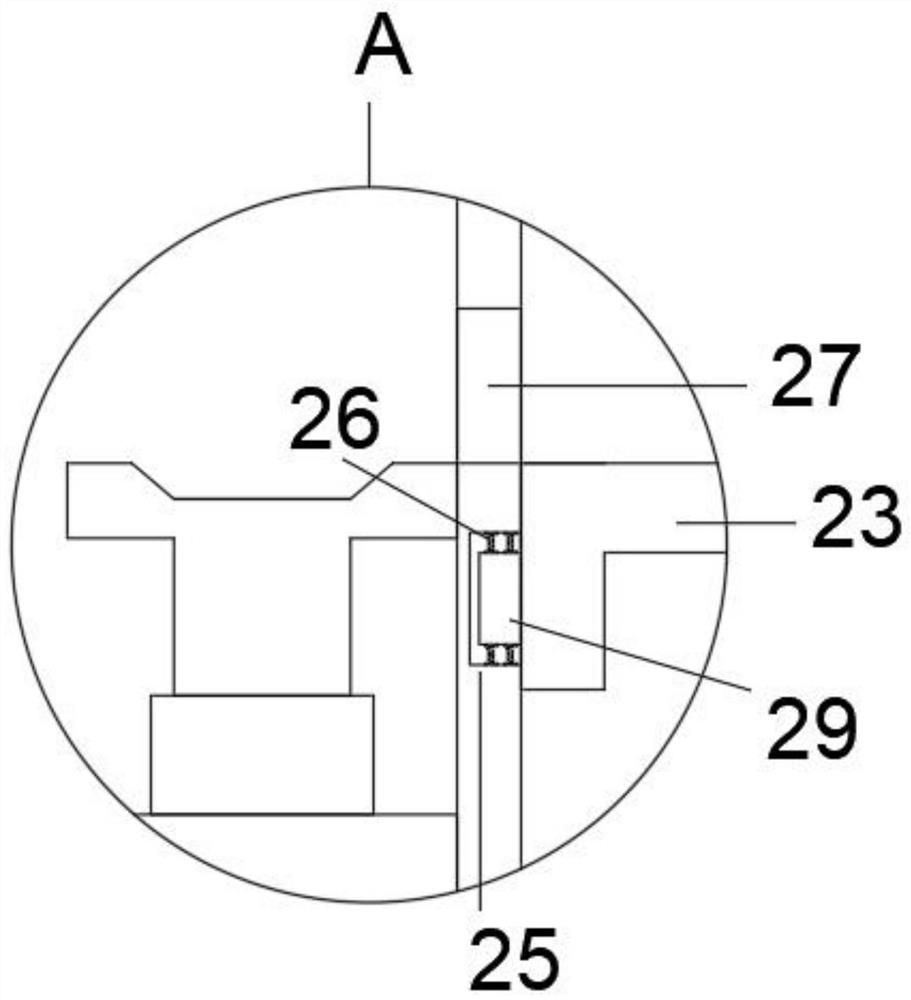

[0027] Described screening mechanism 2 comprises screening box 21, and the inside of described screening box 21 is provided with some screening nets 23, and the mesh diameter of described screening nets 23 decreases successively from top to bottom, wherein the diameter of bottommost screening net 23 Less than 0.5mm, the bottom of the screen 23 is equipped with a vibrating motor 24, and the two ends of the screen 23 are fixedly connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com