Roller nail recoil type nail puller for high-pressure roller mill

A high-pressure roller grinding and nail puller technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of high flatness requirements on the upper and lower edges of the coaxiality sleeve of the middle part, and the easy generation of screw-type nail pullers. The problems of rust jamming failure and high manufacturing precision requirements of screw-type nail pullers can achieve the effect of reducing costs and labor intensity of workers, good welding effect and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

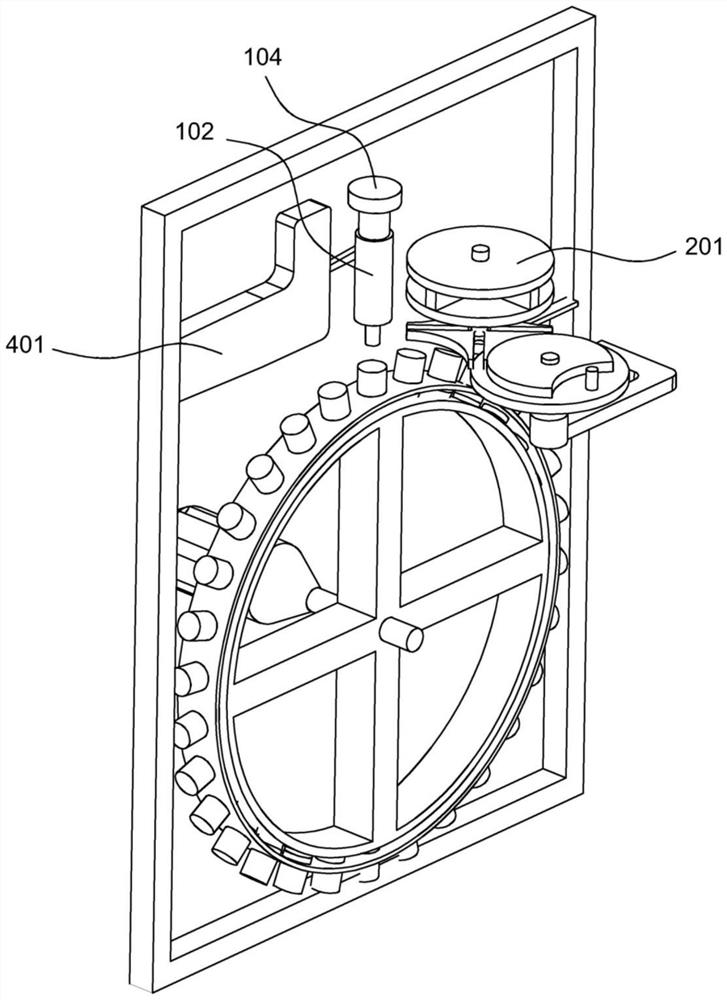

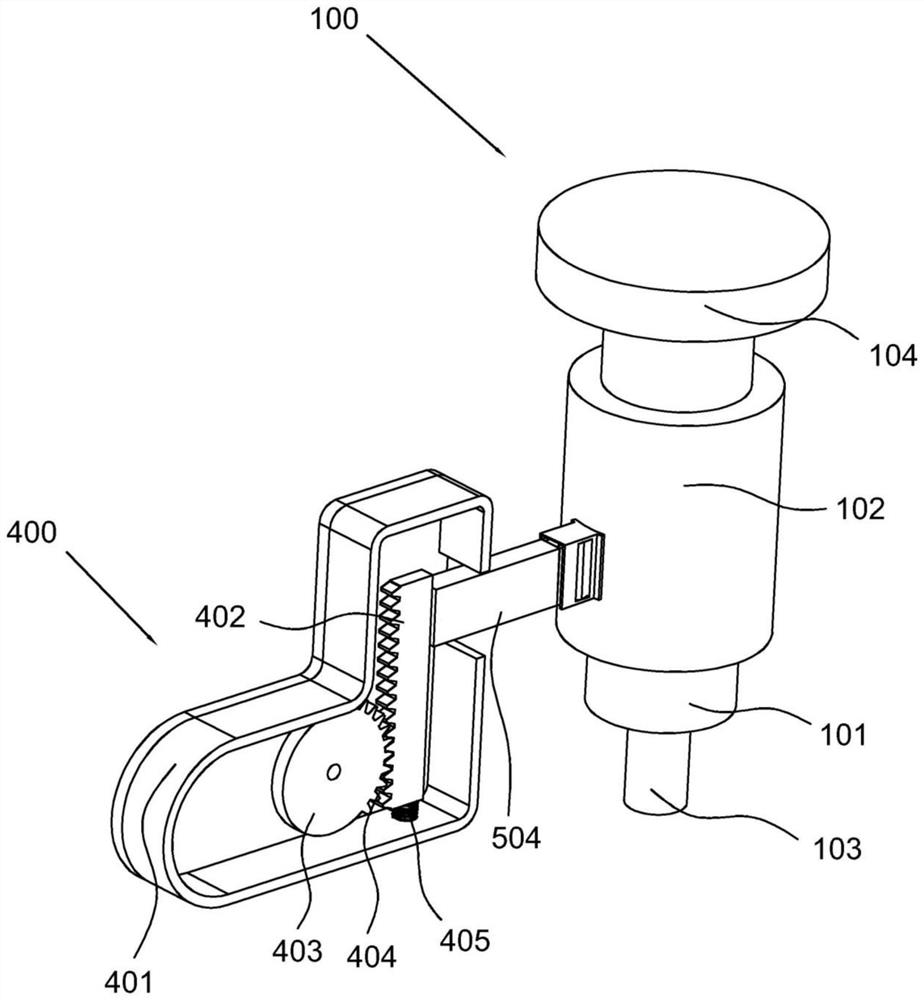

[0035] refer to Figure 1-5 , a high-pressure roller mill roller nail recoil type nail puller, comprising, a nail pulling assembly 100, including a nail pulling middle tube 101, a sleeve 102 set outside the nail pulling middle tube 101, and a nail pulling middle tube The nail-pulling shaft 103 at the end of 101, the nail-pulling middle tube 101 rear end is provided with a stopper 104; the nail-pulling preparation assembly includes a grinding head arranged near the roller nail ring, and a roller nail placed near the roller nail ring The spray gun and the gluing part arranged near the spray gun, the roller nail ring is provided with a position replacement part 200 for driving the gluing part and spray gun position selection; and the driving assembly 400, the driving assembly 400 is arranged at the nail pulling assembly 100 .

[0036] Specifically, the body of the present invention includes a nail-pulling assembly 100. In this embodiment, the nail-pulling assembly 100 is arranged ...

Embodiment 2

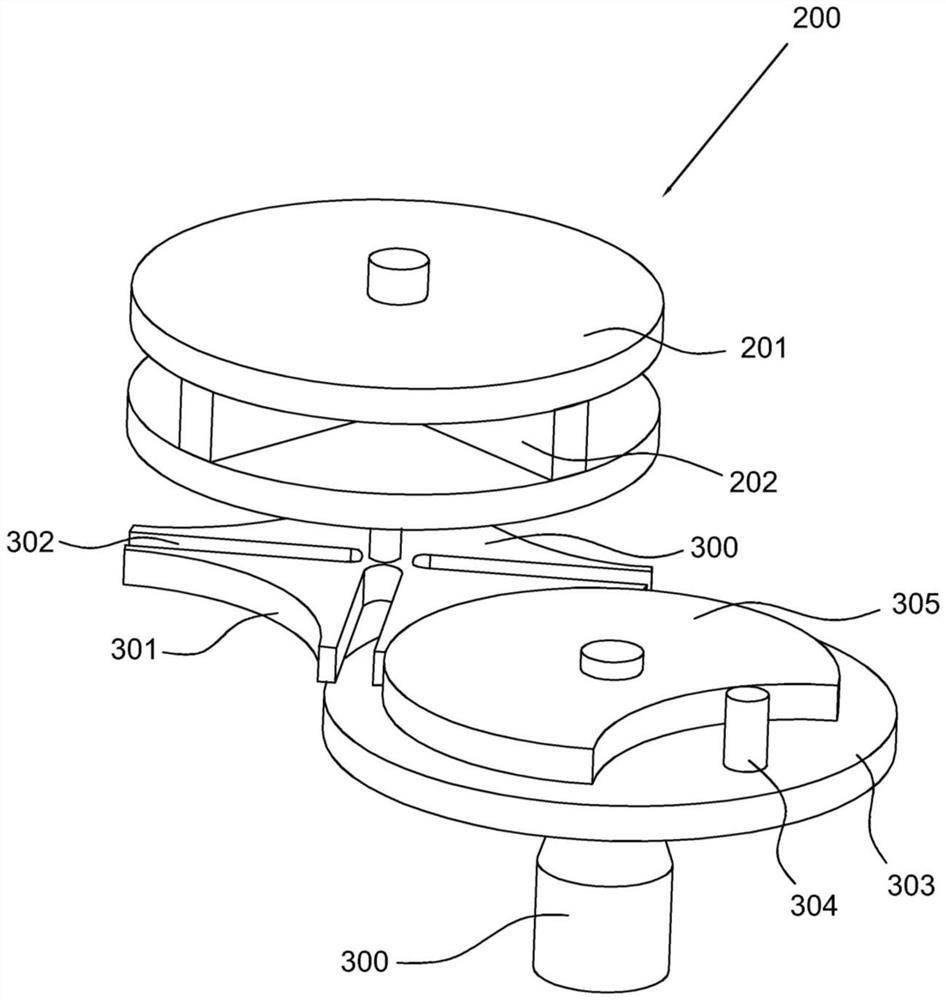

[0041] refer to Figure 1-5 , This embodiment is different from the first embodiment in that: the position replacement part 200 includes a rotary disk 201, a storage groove 202 opened on the outer wall of the rotary disk 201, and a sliding block 203 arranged in the storage groove 202, wherein, Spray gun and gluing part are connected on the sliding block 203 respectively, and the notch place of storage tank 202 is connected with switch plate 204 along the vertical direction sliding, and the rear end of sliding block 203 is provided with the electric motor that drives sliding block 203 to slide. Cylinder 205, the lower end of switch plate 204 is provided with the first slope, and the front end of sliding block 203 protrudes outwards to have drive plate 206, and drive plate 206 is provided with inclined plate 207 near the side wall both sides of storage tank 202, and is set on the inclined plate 207 There is a second inclined surface corresponding to the first inclined surface, a...

Embodiment 3

[0048] refer to Figure 1-5 , This embodiment is different from the above embodiments in that: the driving assembly 400 includes a starting cylinder 401 arranged near the sleeve 102, a rack 402 slidingly connected in the starting cylinder 401 in the vertical direction, and a rack 402 rotatably connected in the starting cylinder 401 The driving wheel 403 in 401, wherein, the driving wheel 403 is provided with a gear tooth 404, and the gear tooth 404 is provided at a position on a quarter of the driving wheel 403, and a driving tooth is provided between the lower end of the rack 402 and the starting cylinder 401. The spring 405 that the bar 402 moves up, the rack 402 protrudes outwards and the connecting rod is connected with the sleeve 102, the lower end of the middle tube 101 protrudes outwards with a flanging, and the flanging is provided with a ring groove that matches the sleeve 102 , a connecting buckle 500 protrudes outward from the side wall of the sleeve 102, a card edg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com