A high-precision acoustic film intelligent punching production line based on visual positioning function

A visual positioning, high-precision technology, used in metal processing, conveyor objects, transportation and packaging, etc., can solve problems such as errors and affect the quality of sound film punching, and achieve the effect of precise processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

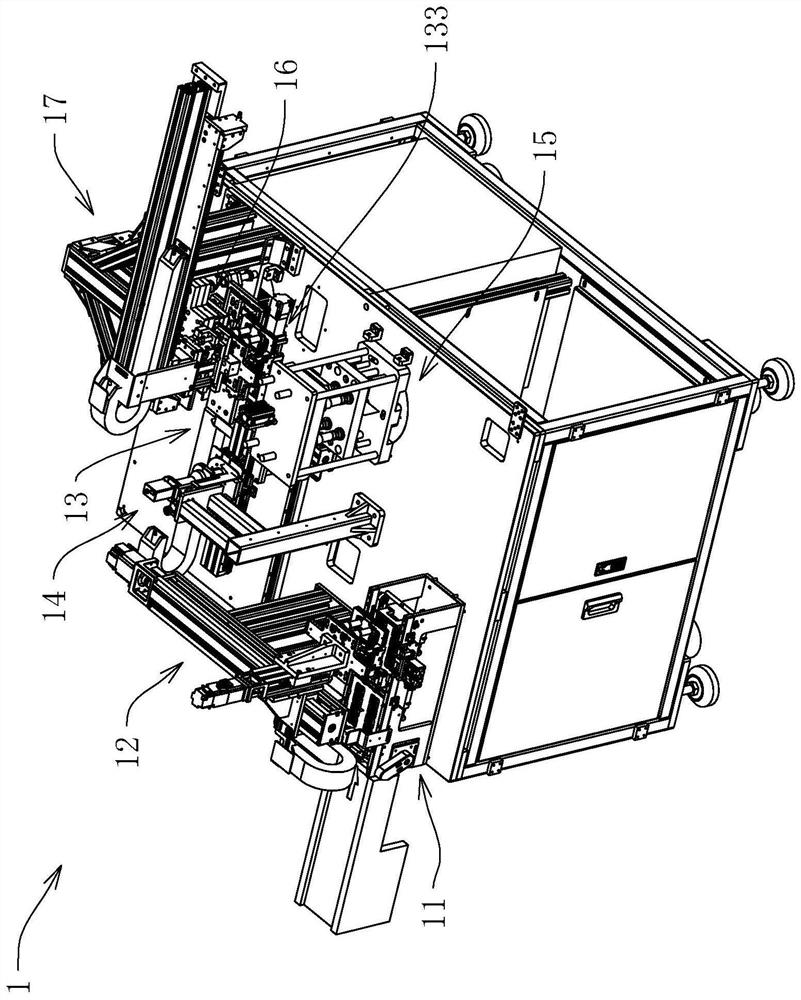

[0057] Attached to the following Figure 1-14 This application will be described in further detail.

[0058] The embodiment of the present application discloses a high-precision acoustic film intelligent punching production line based on a visual positioning function.

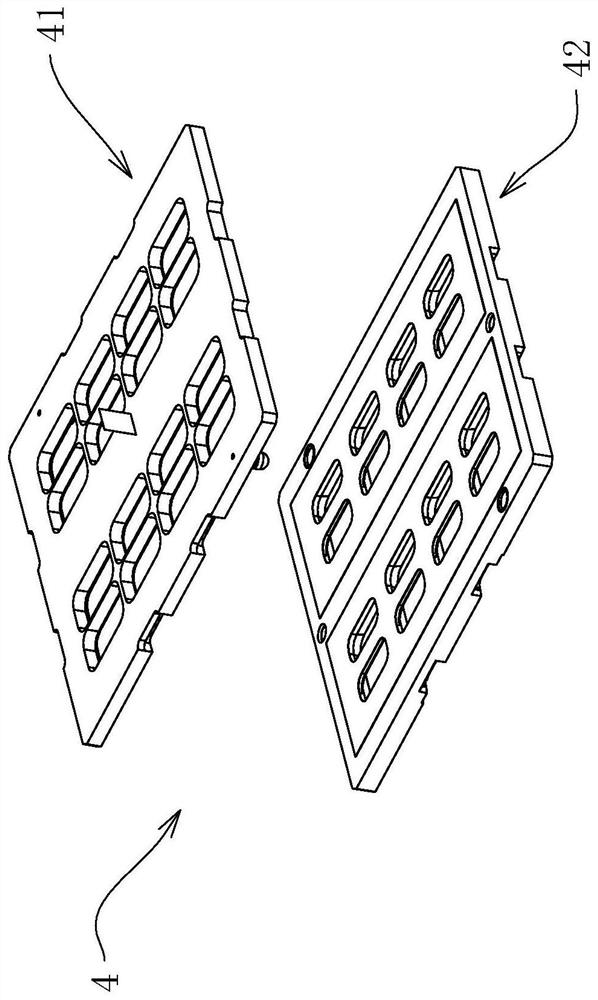

[0059] refer to figure 1 , is the acoustic membrane strip and the fixture assembly 4 for placing the acoustic membrane strip. There are two acoustic membrane strips. Each acoustic membrane strip is evenly distributed with 8 acoustic membranes to be punched, and the acoustic membrane is hollow and oval. The jig assembly 4 is divided into an upper jig 41 and a lower jig 42 . The acoustic membrane tape is attached to the lower jig 42 and is pressed by the upper jig 41 .

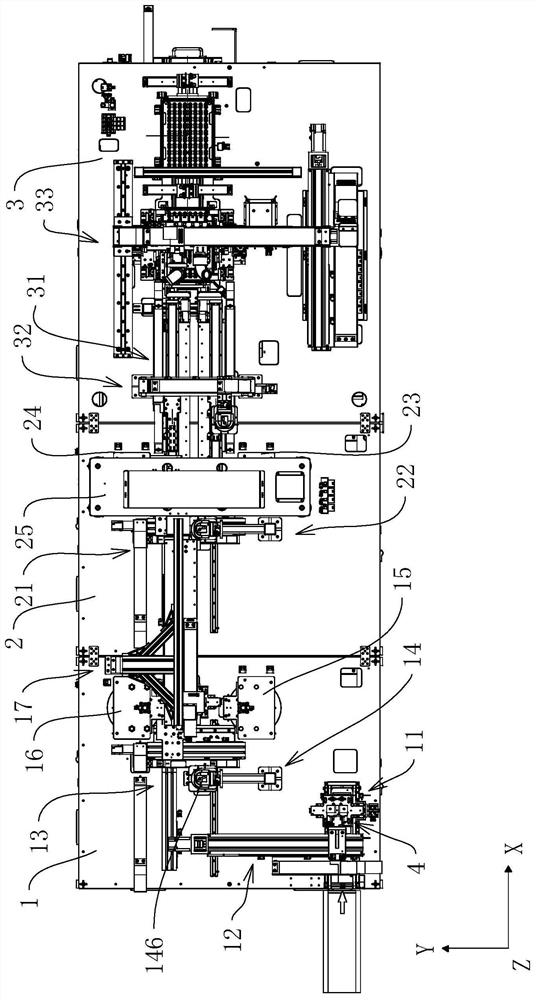

[0060] refer to figure 2 , the production line sequentially includes a first work station 1, a second work station 2 and a third work station 3 along the processing direction of the acoustic membrane. Take the length direction of the horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com