A full-color 3D printer control method based on texture mapping

A 3D printer and texture mapping technology, applied in the field of 3D printers, can solve problems such as technical difficulty, dependence on proficiency, time-consuming and laborious, and achieve the effects of good controllability, simple hardware implementation, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

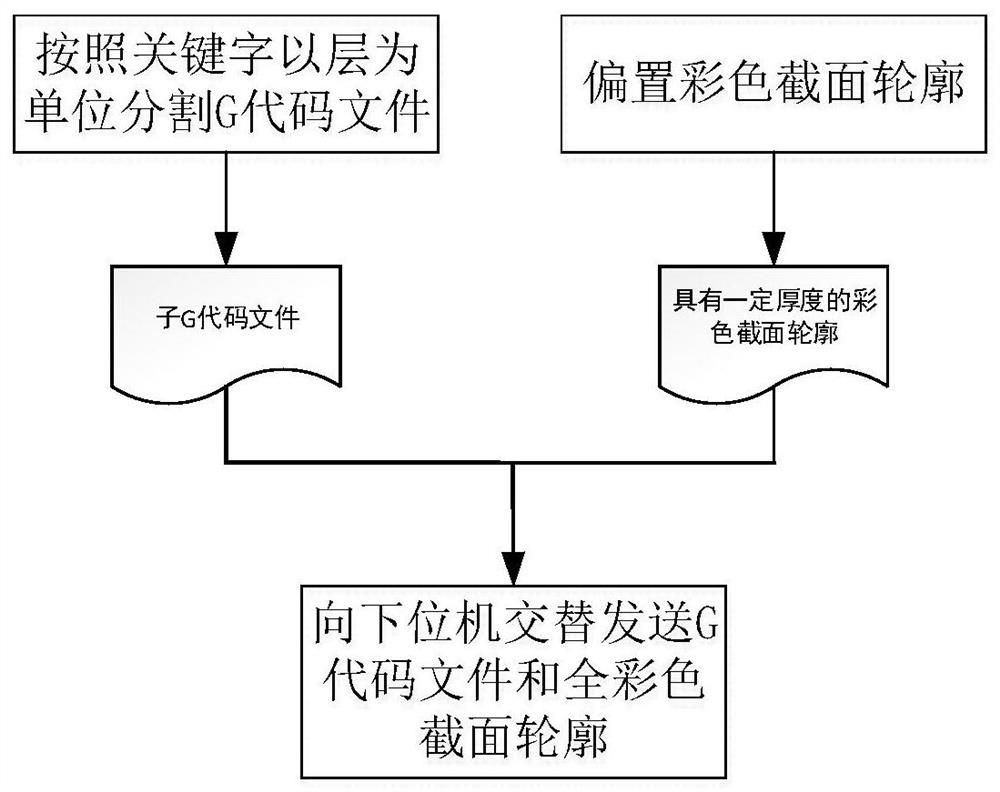

[0048] refer to figure 1 , a full-color 3D printing control method based on texture mapping, including:

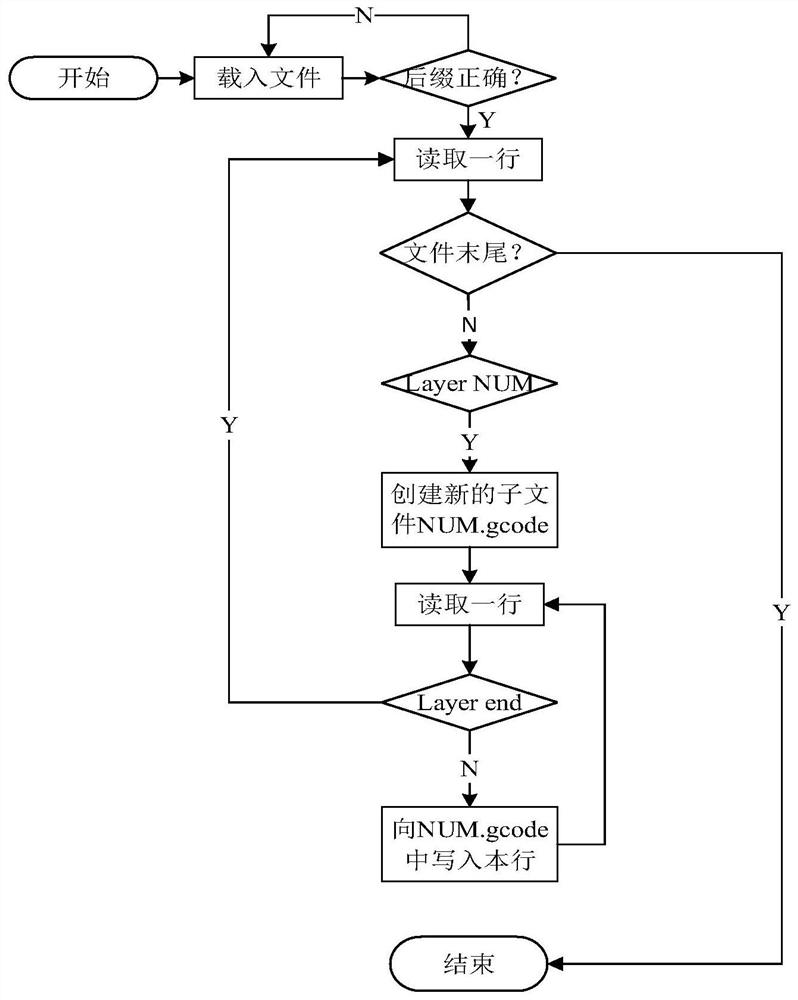

[0049] A Correctly read the G code file, divide it in layers according to keywords, and generate several sub-files;

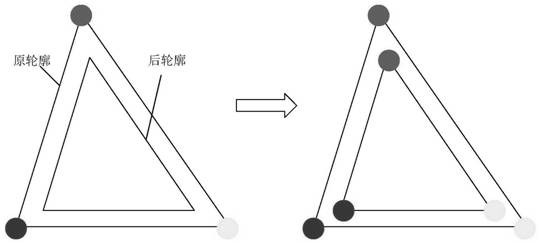

[0050] B. Offset the color cross-sectional profile. According to the difference between the inner and outer contours, the selected offset direction is also different, and finally obtain a color cross-sectional profile image with a certain thickness;

[0051] C alternately sends G-code files and full-color cross-sectional contour images to the lower computer of the full-color 3D printer layer by layer, and alternately drives the print head and inkjet head of the full-color 3D printer to print the substrate and color the contour respectively.

[0052] The G-code file generated after the 3D model is processed by layered slic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com