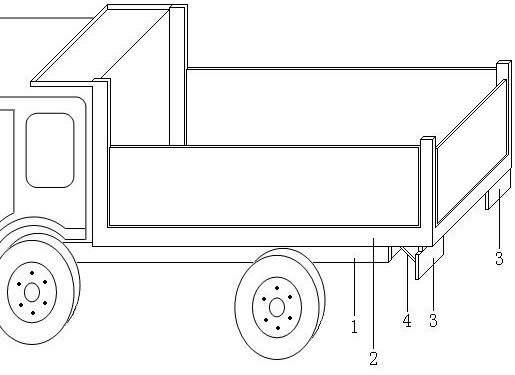

Tail lamp folding bracket of dump truck

A technology for folding brackets and dump trucks, which is applied to vehicle components, optical signals, signal devices, etc., can solve the problems of taillights not functioning properly, contamination, and continuous collision with sediment and soil dumped on the ground.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

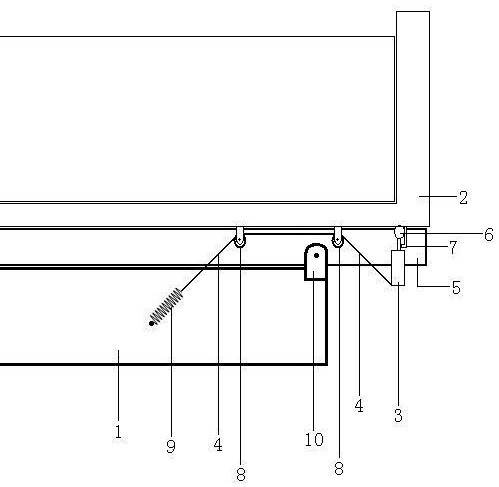

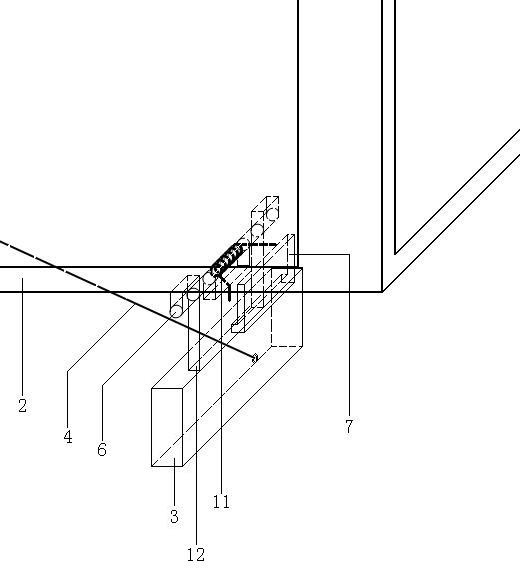

[0015] Now describe in detail the shape and structure of the present invention in conjunction with accompanying drawings and reference numerals:

[0016] A rear taillight folding bracket of a dump truck is characterized in that it includes a girder 1, a cargo box floor 2, a taillight bracket 3, a steel wire rope 4, a subbeam 5, a rotating shaft 6, a baffle plate 7, a support wheel 8, a tension spring 9, a support Ear 10, return spring 11, rotating bracket 12;

[0017] The crossbeam 1 is rectangular, and a D-shaped lug 10 is respectively arranged on the front and back of the top on the right side, and the front and back sides of the middle part on the right side are respectively connected to the bottom of a tension spring 9 by a bolt;

[0018] The sub-beam 5 is rectangular, arranged on the top of the girder 1, and the width is equal to that of the girder 1, and the front and rear sides of the rear are respectively connected to the two lugs 10 by a cylindrical pin;

[0019] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com