Built-in sliding plug door system of high-speed motor train unit

A high-speed EMU and door leaf technology, which is applied in door devices, door/window accessories, hydraulic/pneumatic locks, etc., can solve the requirements of large plug volume, cannot guarantee the safety of the door system, airtight door leaf deformation, and cannot meet the requirements And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

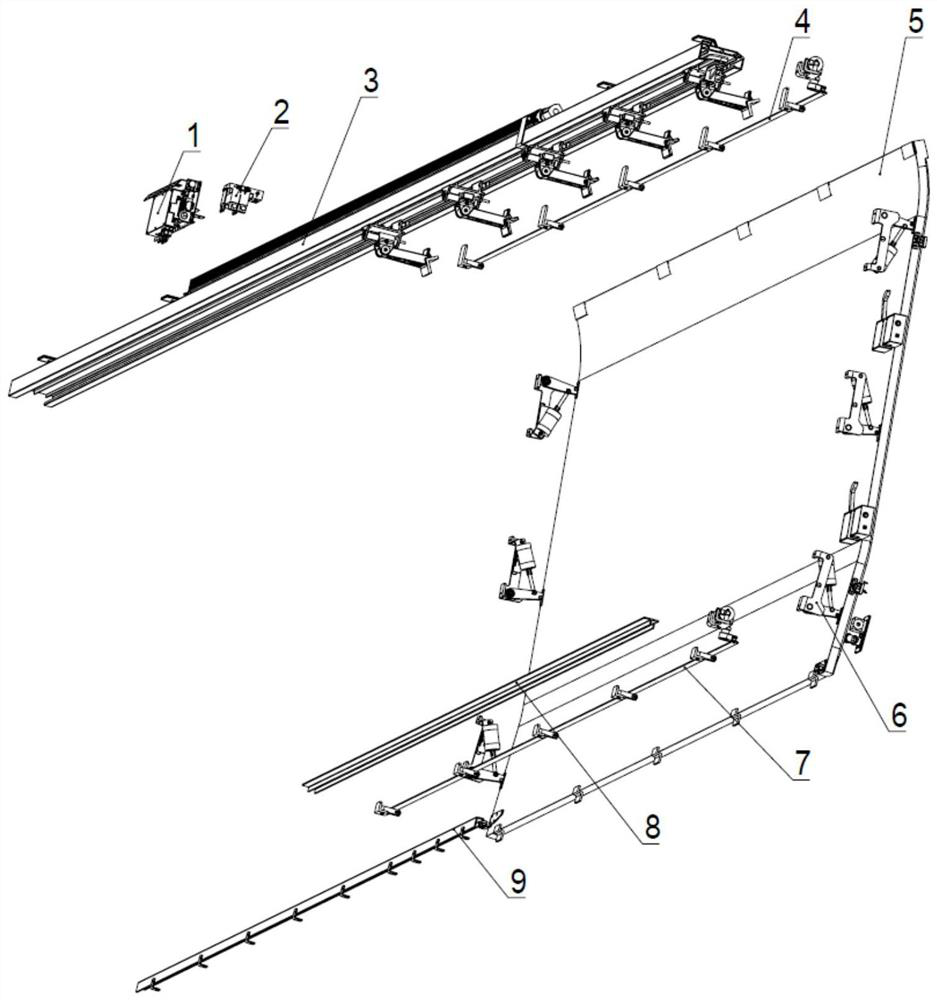

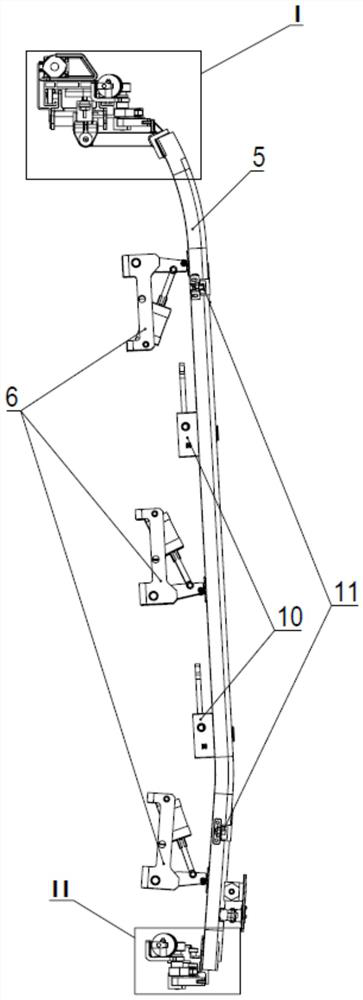

[0022] Such as figure 1 and 2 As shown, the high-speed EMU built-in plug door system described in this embodiment includes a door leaf 5, a bearing driving mechanism 3 and a compression locking device. The bearing driving mechanism 3 is arranged on the top of the door leaf 5, and the compression locking device includes The single-point pneumatic compression locking device 6 and the linkage pneumatic compression locking device, the single-point pneumatic compression locking device 6 is arranged on both sides of the entrance of the car body; The upper part of both ends interlocks and compresses the locking device 4 and the lower part interlocks and compresses the locking device 7 .

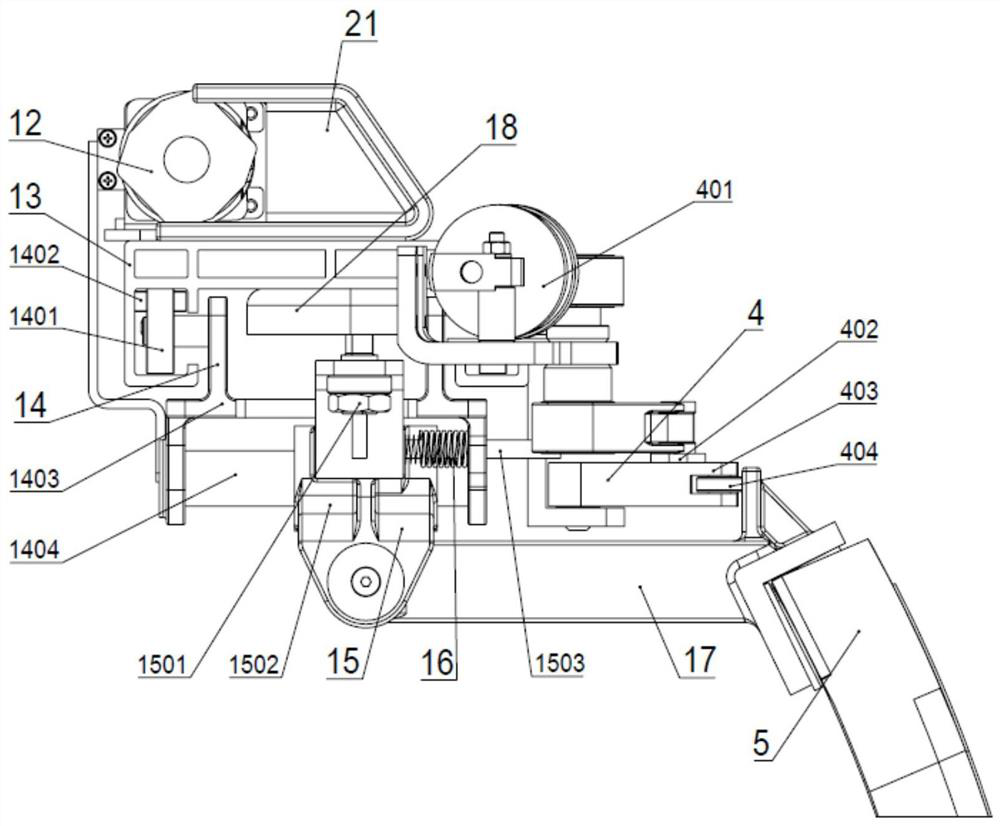

[0023] Define the length direction of the car body as the X direction, and the direction perpendicular to the door leaf 5 as the Y direction. Such as Figure 3-4 As shown, the load driving mechanism 3 includes a load guide rail 13 and an electric cylinder 12, the load guide rail 13 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com