Freshness protection package heat sealing device and heat sealing method facilitating material filling

A heat-sealing device and fresh-keeping bag technology, applied in packaging, solid materials, transportation packaging, etc., can solve the problems of easy adsorption and inability to fill materials, and achieve the effect of avoiding material overflow and material flying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

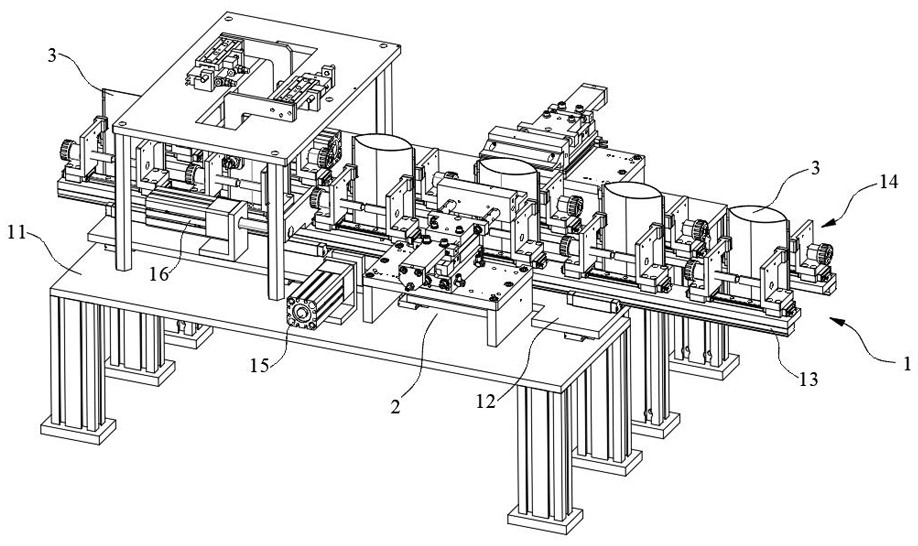

[0037] Such as Figure 1 to Figure 12 As shown, the general fresh-keeping bag heat-sealing device is composed of two parts, two bag-clamping mechanisms 1 and two heat-sealing mechanisms 2 arranged in mirror images. 2. The heat-sealed bags 3 can be close to each other, and the bags 3 can be separated from each other after the heat-sealing is completed, and the bags 3 can be filled with material after the bags 3 are opened. The bag body 3 is clamped by the bag clamping mechanism 1 and then transported to the station of the heat-sealing mechanism 2, and then the bag body 3 is heat-sealed by the heat-sealing mechanism 2. This method has the following problems: the existing bag body 3 is stretched At this time, only the upper part can be stretched, and the lower part is still easy to be adsorbed together due to the existence of static electricity. At this time, when filling the bag body 3, the bottom may not be able to fill the material, which will easily cause the bag body 3 mater...

Embodiment 2

[0059] On the basis of Embodiment 1, this Embodiment 2 also provides a heat-sealing method of a heat-sealing device for a fresh-keeping bag that is convenient for filling. A specific heat-sealing device for a fresh-keeping bag that is convenient for filling is the same as that of Embodiment 1. I won't repeat them here.

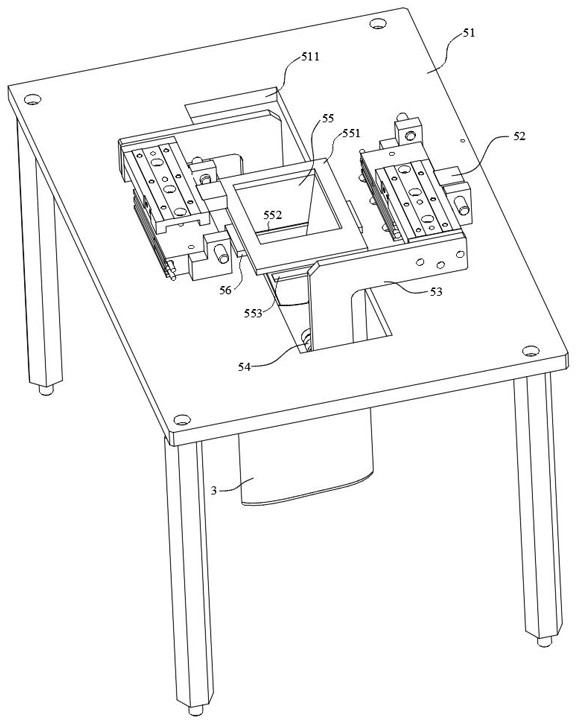

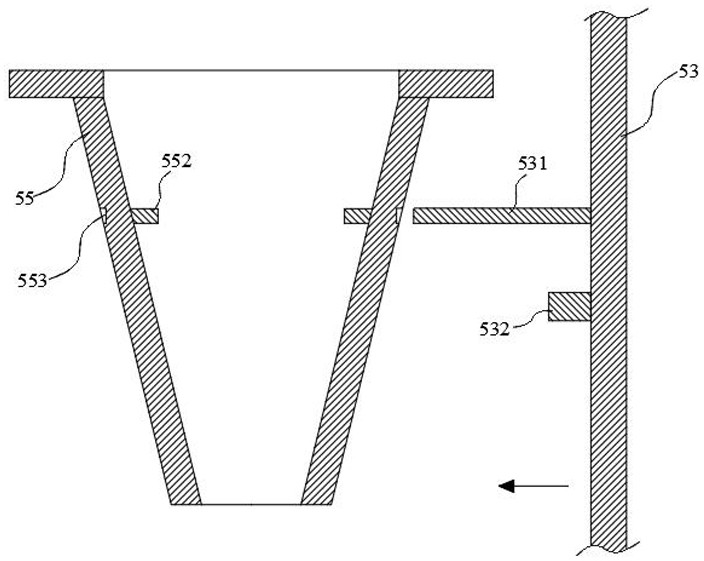

[0060] The specific heat-sealing method of the fresh-keeping bag heat-sealing device that is convenient for filling is as follows, turn the second cross bar 145 to adjust the distance between the two bag side plates 142; push the bag bottom plate 12 to slide through the first bag bag cylinder 15, Make the opposite two clamping blocks 143 clamp the bag body 3; push the bag clamping bottom rail 13 to slide through the second bag clamping cylinder 16, so that the clamped bag body 3 slides between the two stretching air nozzles 54; Stretch the air nozzle 54 to absorb the bag body 3; push the stretch air nozzle 54 to slide through the stretch cylinder 52 to make th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com