Dam air bag conveying belt

A conveyor belt and airbag technology, applied in the field of dam airbag conveyor belts, can solve the problems of inconsistency and large disparity in tensile strength, and achieve the effect of improving elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

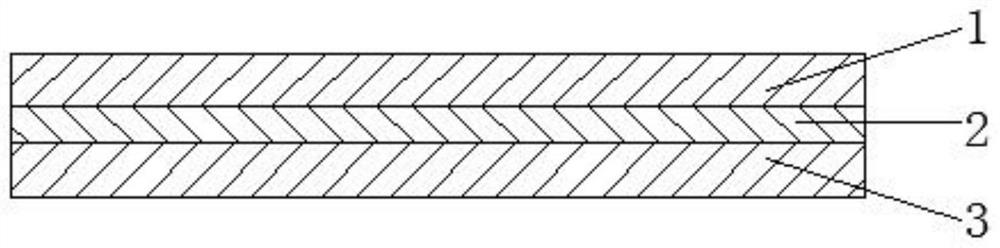

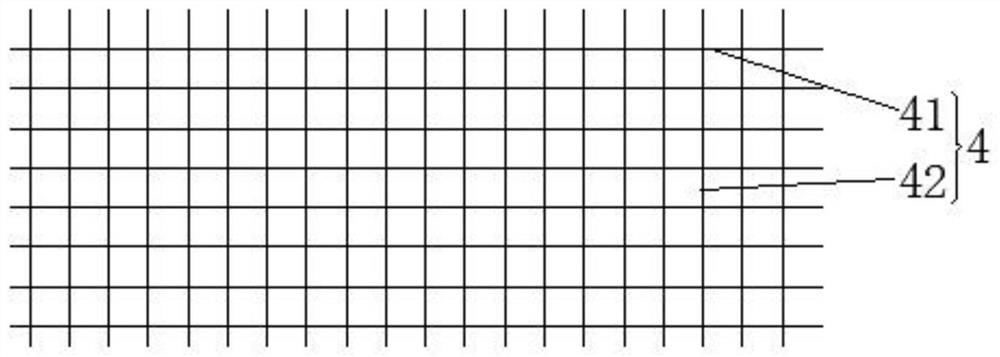

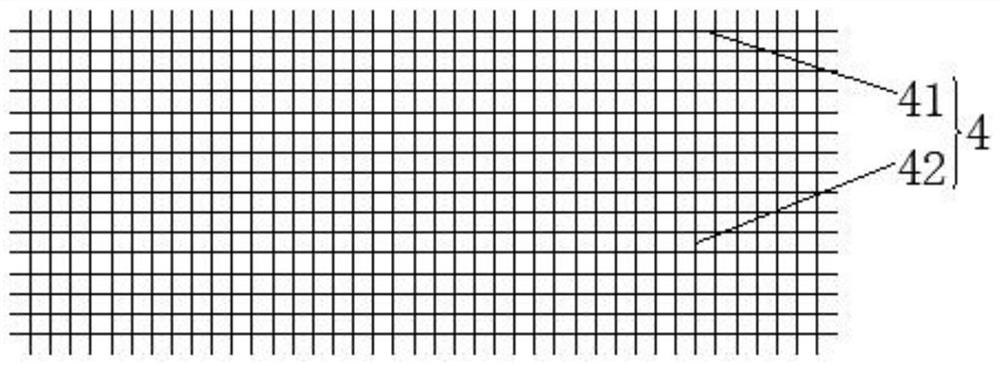

[0030] The first cover rubber layer 1 and the second cover rubber layer 3 are closely attached to the skeleton layer 2 by calendering technology. The skeleton layer 2 is a single-layer canvas 4, wherein the canvas 4 is provided with a plurality of through holes, and the setting of the through holes It is possible to form an integrally formed glue column with the first cover rubber layer 1 and the second cover rubber layer 3 during the calendering process, which is conducive to improving the bonding strength between the first cover rubber layer 1 and the second cover rubber layer 3, And then effectively improve the radial fracture strength and latitudinal fracture strength, the canvas 4 selects the NN-66 model, the thickness of the canvas 4 is 0.9mm, and the thickness of the first cover rubber layer 1 and the second cover rubber layer 3 is 1mm , the density of the warp 41 and the weft 42 is 10 threads / cm, the cover rubber in the first cover rubber layer 1 and the second cover ru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com