Main rack for loop chain chain block

A chain hoist and main frame technology, applied in portable lifting devices, hoisting devices, etc., can solve the problems of unreliable meshing transmission, low assembly efficiency, twisting, turning or even jamming of lifting chain 41, so as to prevent mutual Squeeze and impact, improve the reliability of meshing transmission, and overcome the hidden danger of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

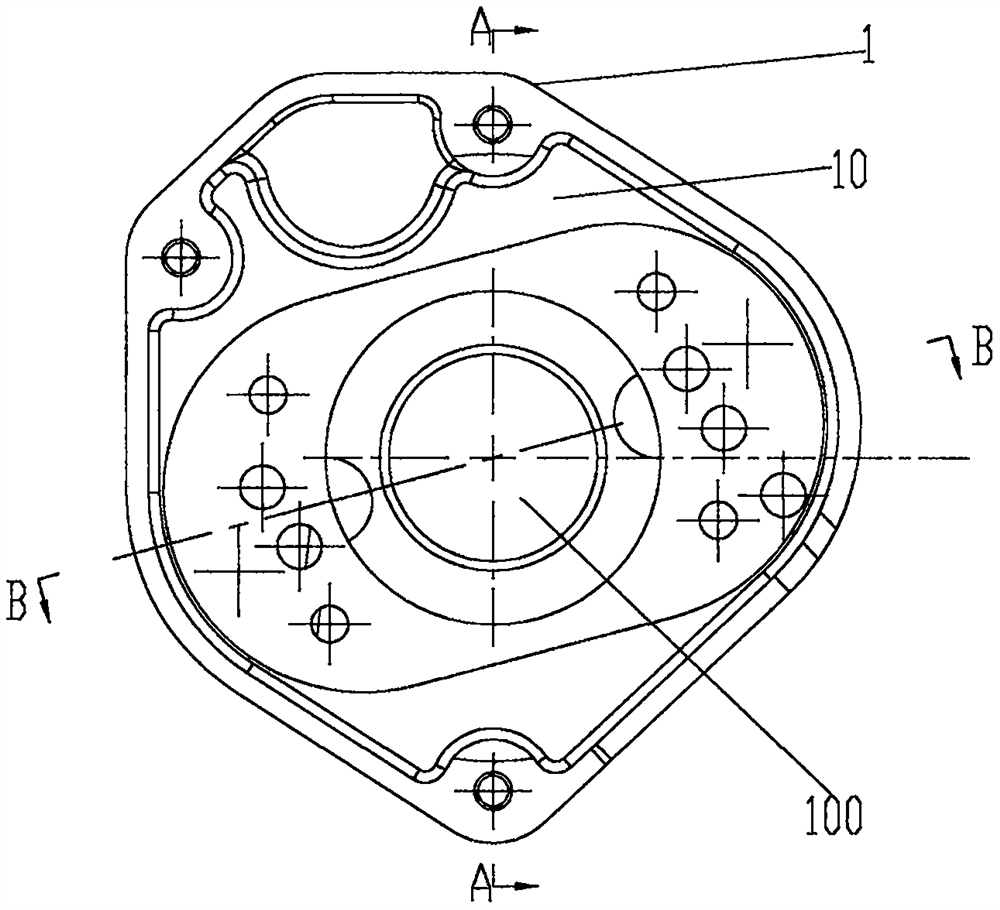

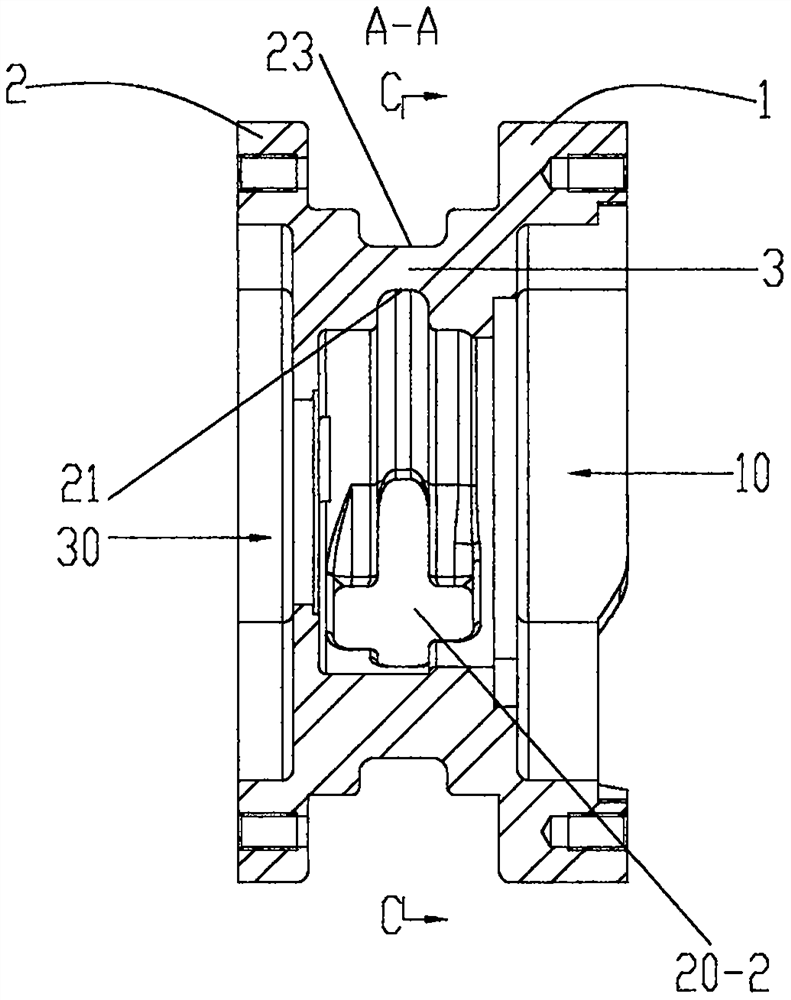

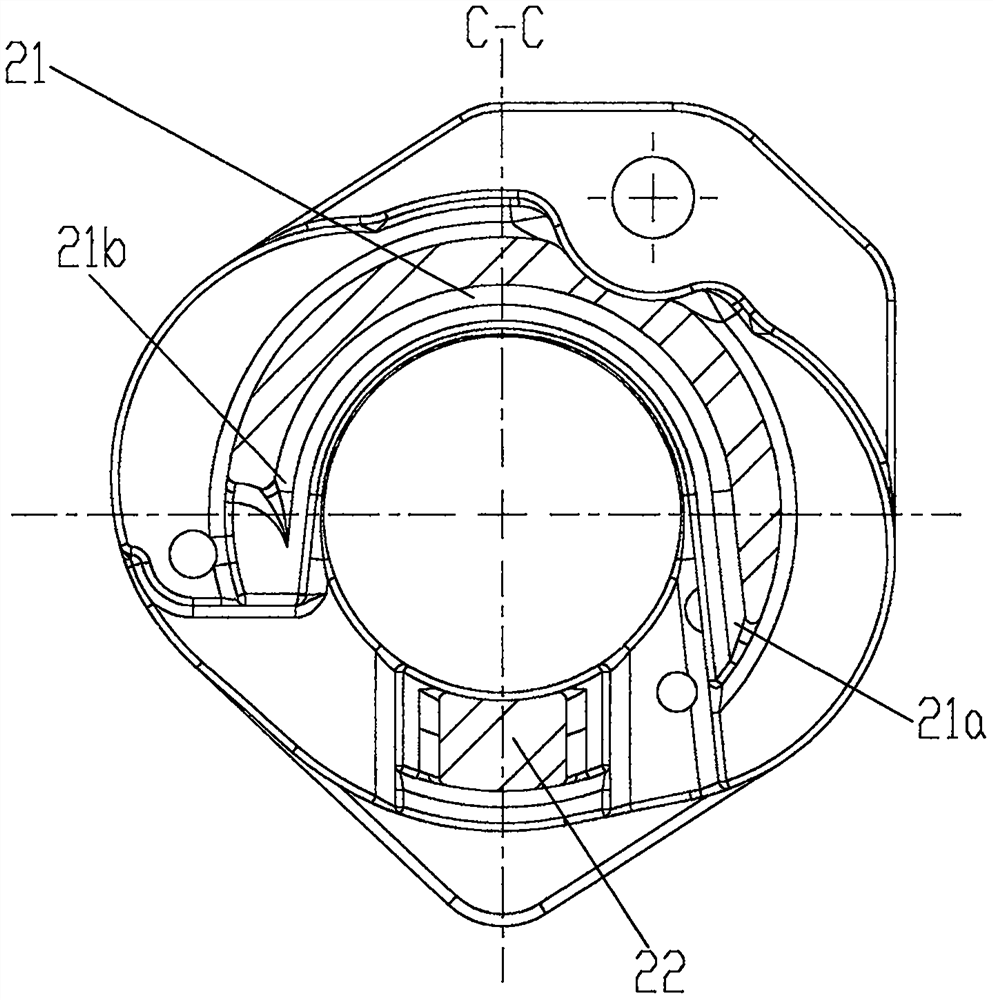

[0025] see Figure 1-4 As shown, a main frame for a chain hoist is a single part, including a drive side frame part 1, a deceleration side frame part 3, and an integrally connected drive side frame part 1 and a deceleration side frame part 3. The middle connecting part 2 has an arc-shaped chain guide groove 21 on the inner wall of the upper area of the middle connecting part 2, and a chain-feeding cross is opened between the bottom area of the middle connecting part 2 and one end 21a of the arc-shaped chain guide groove 21. Hole 20-1, between the bottom area of the intermediate connecting part 2 and the other end 21b of the arc-shaped chain guide groove 21, there are chain-out cross holes 20-2, chain-in cross holes 20-1 and chain-out cross holes 20- 2, so that the middle connecting part 2 forms a bump part 22 for the function of the chain at the bottom between the chain-entry cross hole 20-1 and the chain-out cross hole 20-2, and the drive side frame part 1 The outer si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com