Cement-based capillary crystalline waterproof coating and preparation method thereof

A osmotic crystalline waterproofing and cement-based technology, which is applied in the field of building waterproofing materials, can solve the problems of non-permanent waterproofing effect, achieve the effects of improving non-permanent waterproofing effect, excellent impermeability and waterproof performance, and increasing impervious pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0047] Preparation example 1 provides a kind of calcium aluminate modified by silane coupling agent, and its preparation steps are:

[0048] (1) Add 40 g of vinyltriethoxysilane into 200 mL of 30 wt % ethanol aqueous solution, stir evenly, adjust the pH of the solution to 4, and stir to obtain a silane coupling agent solution;

[0049] (2) Add 50 g of calcium aluminate into 100 mL of silane coupling agent solution, stir, filter, wash, and dry to obtain calcium aluminate modified by silane coupling agent.

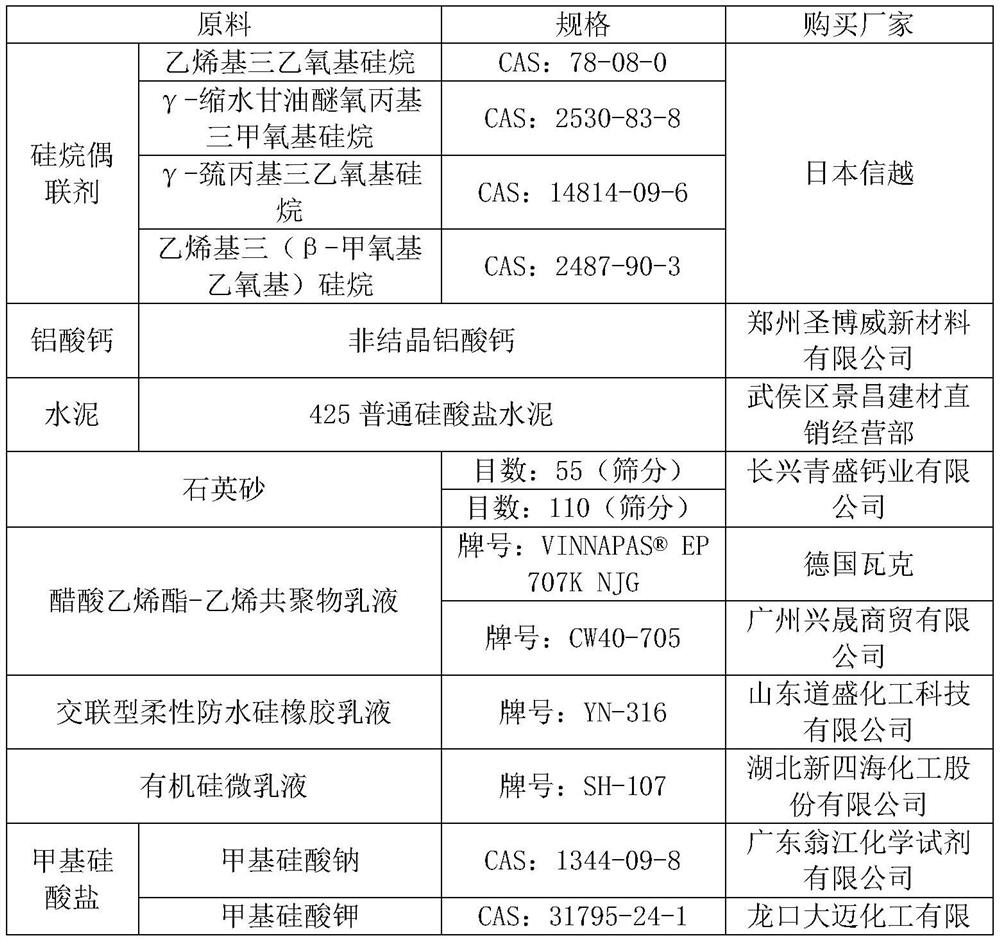

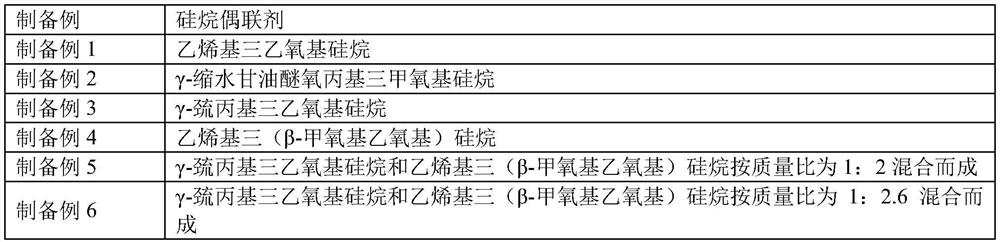

[0050] Preparation Examples 2-6 are the same as Preparation Example 1, except that the silane coupling agent is different, see Table 2 for details.

[0051] Table 2

[0052]

Embodiment 1

[0056] Embodiment 1 provides a kind of cement-based permeable crystalline waterproof coating, and its preparation steps are as follows:

[0057] S1: Mix 40g of cement and 20g of quartz sand, stir, then add 5g of calcium aluminate modified by a silane coupling agent, and stir to obtain a powder;

[0058] S2: Mix 15g vinyl acetate-ethylene copolymer emulsion, 10g cross-linked flexible waterproof silicone rubber emulsion, 10g deionized water and 0.2g additives, stir, then add 5g polyvinyl alcohol and 3g hydroxypropyl methylcellulose , stirring, adding 3g of methyl silicate, stirring to obtain a slurry;

[0059] S3: Mix the powder and the slurry, add water and stir evenly to prepare a cement-based penetrating crystalline waterproof coating that can be used immediately;

[0060] Wherein, the mass ratio of the powder, slurry and water is 1:0.4:0.6; the cement is 425 ordinary Portland cement; the average particle size of the quartz sand is 55 mesh (obtained by further screening); T...

Embodiment 2-3

[0061] Example 2-3 is the same as Example 1, except that the quality of the raw materials for the preparation of the cement-based osmotic crystalline waterproof coating is different, as shown in Table 3 for details.

[0062] table 3

[0063] components Example 1 Example 2 Example 3 cement (g) 40 60 50 Quartz sand (g) 20 30 25 Calcium aluminate modified by silane coupling agent (g) 5 8 7 Vinyl acetate-ethylene copolymer emulsion (g) 15 25 20 Cross-linked flexible waterproof silicone rubber emulsion (g) 10 20 15 Methyl silicate (g) 3 5 4 Hydroxypropyl Methyl Cellulose (g) 3 5 4 Polyvinyl alcohol (g) 5 10 8 Deionized water (g) 10 15 12 Auxiliary dosage (g) 0.2 0.4 0.3 Auxiliary composition (mass ratio of dispersant, film former, defoamer) 1:1.2:0.6 1:1.4:0.8 1:1.3:0.7 Mass ratio of powder, slurry and water 1:0.4:0.6 1:0.6:0.7 1:0.6:0.6

[0064] Examples 4-8 are the sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com