Waterproof decoration plate and production method thereof

A decorative board and portland cement technology, applied in the field of waterproof decorative board and its preparation, can solve the problems of unsatisfactory waterproof effect of decorative board, affect the aesthetics of decorative board, cannot be waterproof, etc., and achieve excellent impermeability and waterproof performance , The appearance is seamless, the effect of protecting the internal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

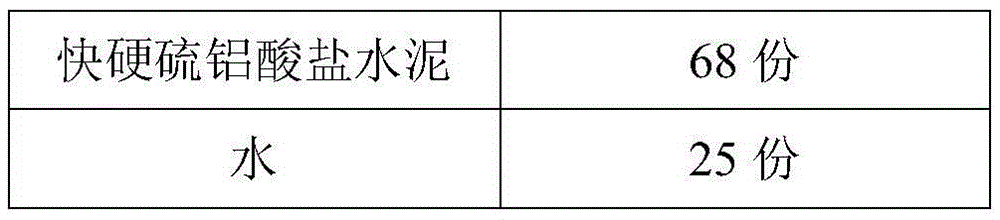

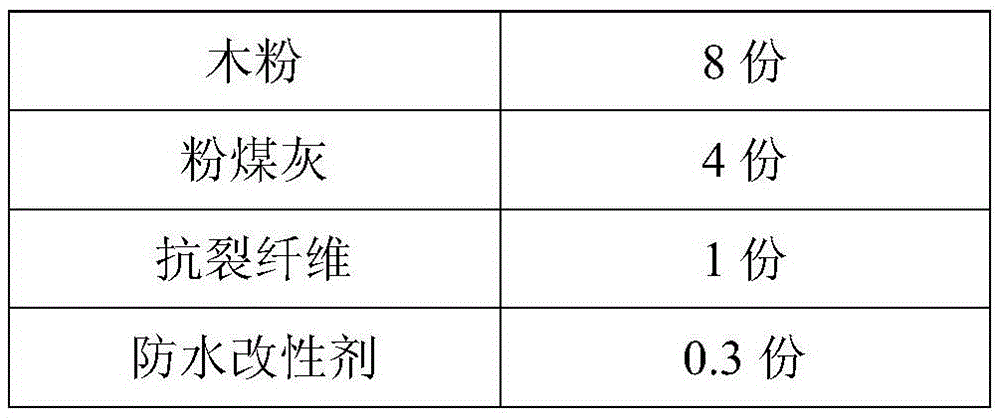

[0037] A waterproof decorative board, its raw materials include the following components:

[0038] Rapid hardening sulfoaluminate cement

68kg

water

25kg

8kg

4kg

anti-crack fiber

1kg

waterproof modifier

0.3kg

[0039] Wherein said waterproof modifier is the following components: 159.4g Portland cement, 8.0g sodium carbonate, 3% calcium chloride solution of 17.3g, 9.3g citric acid, 8.5g pH regulator, 95.7g silica sand and 1.9 g aluminum chloride;

[0040] Carry out following steps according to above-mentioned raw material formula:

[0041] 1. Ingredients: Feed according to the ratio of each component of the waterproof decorative board and stir for 5 minutes to obtain a slurry;

[0042] 2. Pavement: After brushing the release agent in the mold, add 2 layers of glass fiber mesh cloth, and pave the stirred slurry on the glass fiber mesh cloth;

[0043] 3. Surface trimming, the first cu...

Embodiment 2

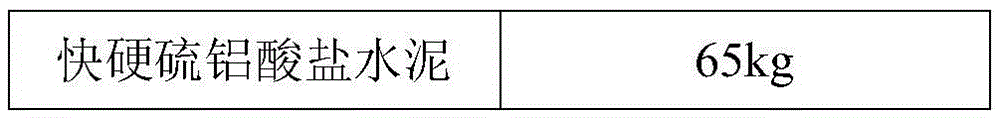

[0048] A waterproof decorative board, its raw materials include the following components:

[0049]

[0050]

[0051] Wherein said waterproof modifier is the following components: 260g Portland cement, 8g sodium carbonate, 3%-5% calcium chloride solution of 20g, 20g citric acid, 28g pH regulator, 160g silica sand and 4g chlorine Aluminum;

[0052] Carry out following steps according to above-mentioned raw material formula:

[0053] 1. Ingredients: Feed according to the ratio of each component of the waterproof decorative board and stir for 5 minutes to obtain a slurry;

[0054] 2. Pavement: After brushing the release agent in the mold, add 2 layers of glass fiber mesh cloth, and pave the stirred slurry on the glass fiber mesh cloth;

[0055]3. Surface trimming, the first curing, the curing conditions are temperature 26-28 ℃, humidity above 80%, curing time 20 hours;

[0056] 4. Cut according to the required specifications;

[0057] 5. Carry out sanding process;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Permeability | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

| Impermeability pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com