A kind of titanium carbide nano powder used for abs flame retardant, smoke suppression and detoxification and preparation method thereof

A nano-powder and titanium carbide technology, which is applied in the field of nano-material preparation, can solve the problems of unreported smoke particles and toxic gases, high surface energy of nanoparticles, poor compatibility, etc., and reduce heat release rate and specific surface area. Large, compatible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

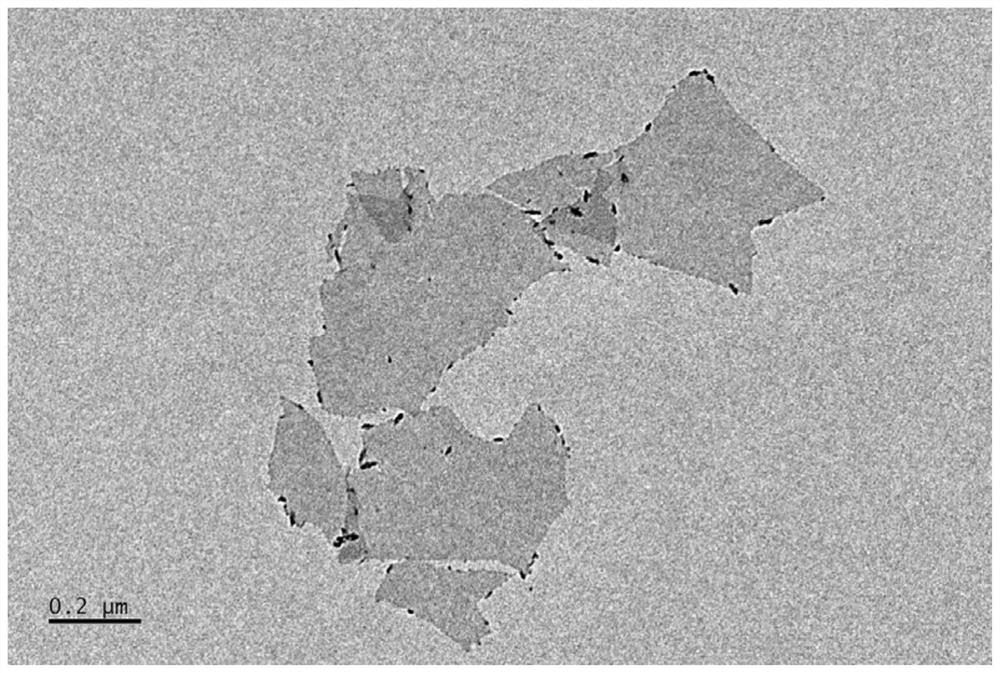

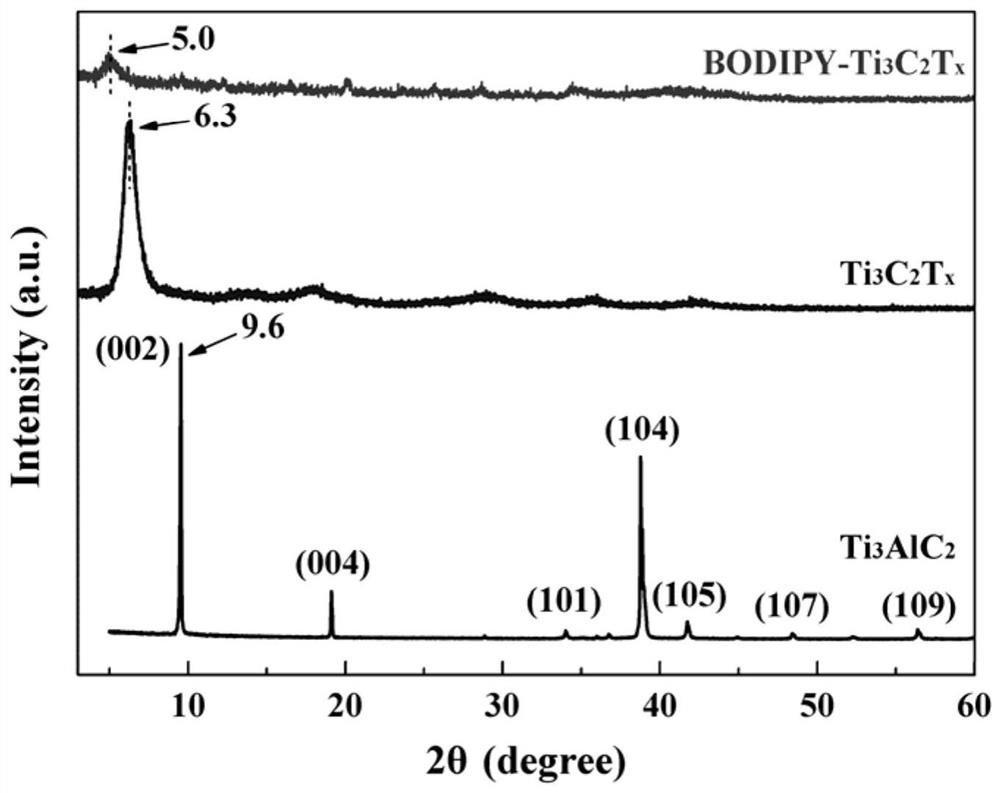

[0041] 1) Take 0.5g of carbon aluminum titanium and 0.5g of lithium fluoride in a plastic beaker, add 10mL of hydrochloric acid with a concentration of 10mol / L, stir and react at 40°C for 48h at a stirring speed of 400rpm, after the reaction is completed, centrifuge repeatedly, After washing to pH 7, titanium carbide was precipitated after drying.

[0042] 2) Take 0.2 g of the precipitated titanium carbide obtained in step 1), disperse it in 50 mL of deionized water, ultrasonicate at 0°C for 30 min, and the ultrasonic power is 300 W, then centrifuge at 5000 rpm to remove the precipitate, and take the supernatant, namely A suspension of titanium carbide nanosheets was obtained.

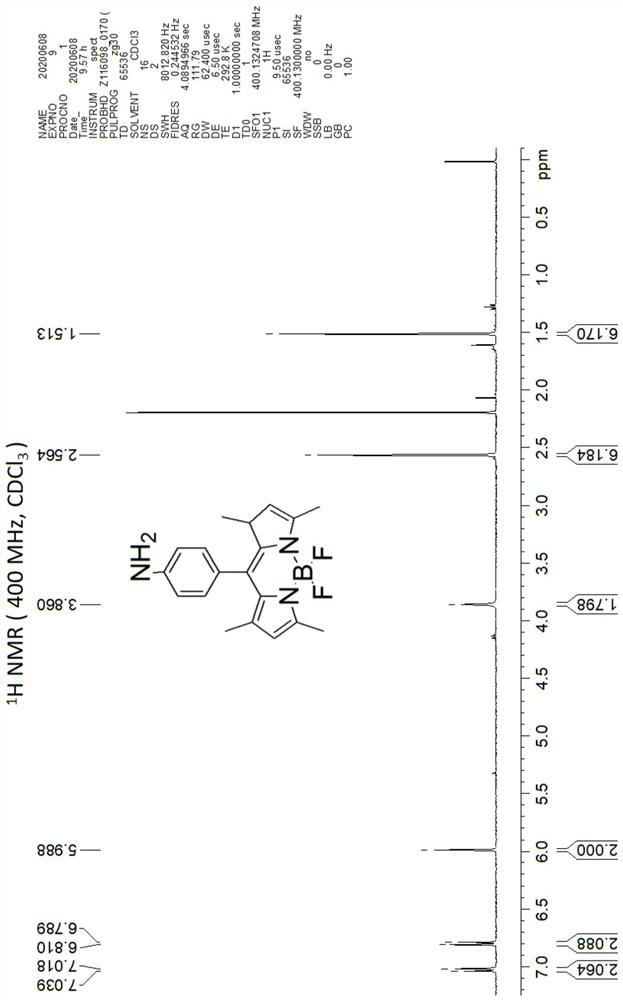

[0043] 3) Dissolve 2.9g of 2,4-dimethylpyrrole and 1.8g of p-nitrobenzaldehyde in 200mL of tetrahydrofuran, protect it with nitrogen, add 1mL of trifluoroacetic acid, react at 25°C for 12h, then add 2.8g of 2 , 3-dichloro-5,6-dicyano-p-benzoquinone, continue to react at 25°C for 4h, add 70mL triethyla...

Embodiment 2

[0054] 1) Take 0.5g of carbon aluminum titanium and 0.5g of lithium fluoride in a plastic beaker, add 12mL of hydrochloric acid with a concentration of 8mol / L, stir and react at 45°C for 40h at a stirring speed of 450rpm, and centrifuge repeatedly after the reaction. After washing to pH 7, titanium carbide was precipitated after drying.

[0055] 2) Take 0.2 g of the precipitated titanium carbide obtained in step 1), disperse it in 50 mL of deionized water, ultrasonicate for 40 min at 1 ° C, and the ultrasonic power is 250 W, then centrifuge at 4500 rpm to remove the precipitate, and take the supernatant, namely A suspension of titanium carbide nanosheets was obtained.

[0056] 3) Dissolve 2.9g of 2,4-dimethylpyrrole and 1.8g of p-nitrobenzaldehyde in 190mL of tetrahydrofuran, pass through nitrogen protection, add 2mL of trifluoroacetic acid, react at 28°C for 16h, then add 2.8g of 2 , 3-dichloro-5,6-dicyano-p-benzoquinone, continue to react at 28°C for 5h, add 75mL triethylam...

Embodiment 3

[0060] 1) Take 0.5g of carbon aluminum titanium and 0.5g of lithium fluoride in a plastic beaker, add 15mL of hydrochloric acid with a concentration of 7mol / L, stir and react at 50°C for 60h, and the stirring speed is 600rpm. After washing to pH 7, titanium carbide was precipitated after drying.

[0061] 2) Take 0.2 g of the precipitated titanium carbide obtained in step 1), disperse it in 50 mL of deionized water, ultrasonicate at 2°C for 50 min with an ultrasonic power of 150 W, then centrifuge at 4000 rpm to remove the precipitate, and take the supernatant, namely A suspension of titanium carbide nanosheets was obtained.

[0062] 3) Dissolve 2.9g of 2,4-dimethylpyrrole and 1.8g of p-nitrobenzaldehyde in 180mL of tetrahydrofuran, protect it with nitrogen, add 3mL of trifluoroacetic acid, react at 30°C for 18h, and then add 2.8g of 2 , 3-dichloro-5,6-dicyano-p-benzoquinone, continue to react at 30°C for 6h, add 80mL triethylamine and 85mL boron trifluoride ether at 2°C, reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com