Electromagnetic depth control steel surface chemical treatment device and method thereof

A surface chemical treatment and treatment method technology, which is applied in the field of heterogeneous steel material preparation, can solve the problems of decreased welding performance and corrosion resistance, difficulty in realizing multi-level control of hardened layer, single control means of carburized layer thickness, etc., to achieve improved Wear resistance, shorter production cycle, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Pretreatment: Grind the 20Cr bar with No. 800, No. 1200 and No. 1600 sandpaper in turn to remove the rust and oxide film on the surface of the bar, remove the oil on the surface with acetone, and carry out pickling to remove the oxide film on the surface. Mark the parts where the magnetic field needs to be applied.

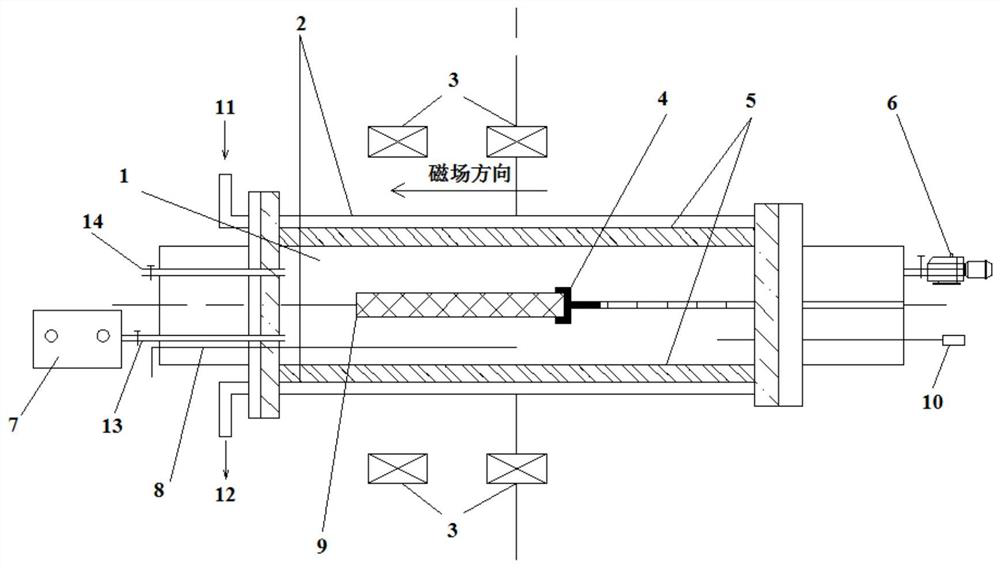

[0033] (2) Vacuumize and heat up: clamp the pretreated bar in such as figure 1 The sample holder in the experimental furnace shown is sealed with a sealing device. Place the part to be magnetized within the range of the magnetic field, turn on the vacuum pump to evacuate, turn off the vacuum pump when the pressure in the furnace is below 1000Pa, adjust the temperature control instrument to control the heating temperature at 950°C, and keep it warm for 30 minutes to ensure that the steel is evenly heated.

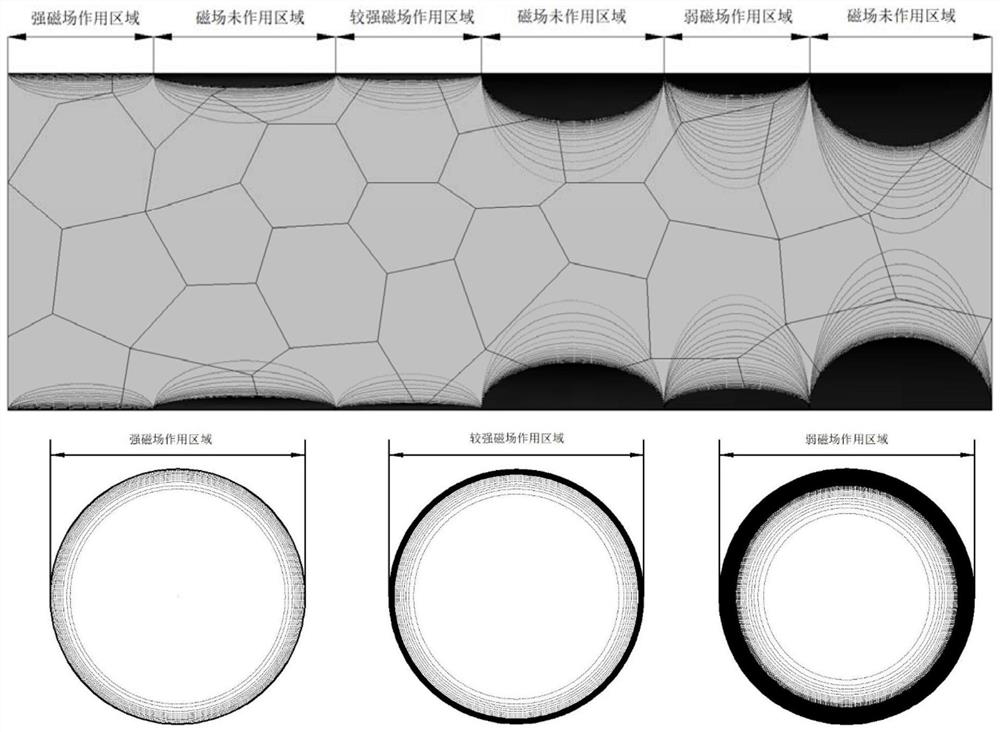

[0034] (3) Electromagnetic control deep carburizing: open the solenoid valve, pass high-purity propane and acetylene into the furnace as carburizing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com