Method for stripping adhesive label paper on surface of paper cultural relic

A technology of paper cultural relics and label paper, applied in cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems affecting the aesthetics of the marked material, damage to the matrix of the marked material, etc., achieve good peeling effect and low cost , the effect of preserving integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

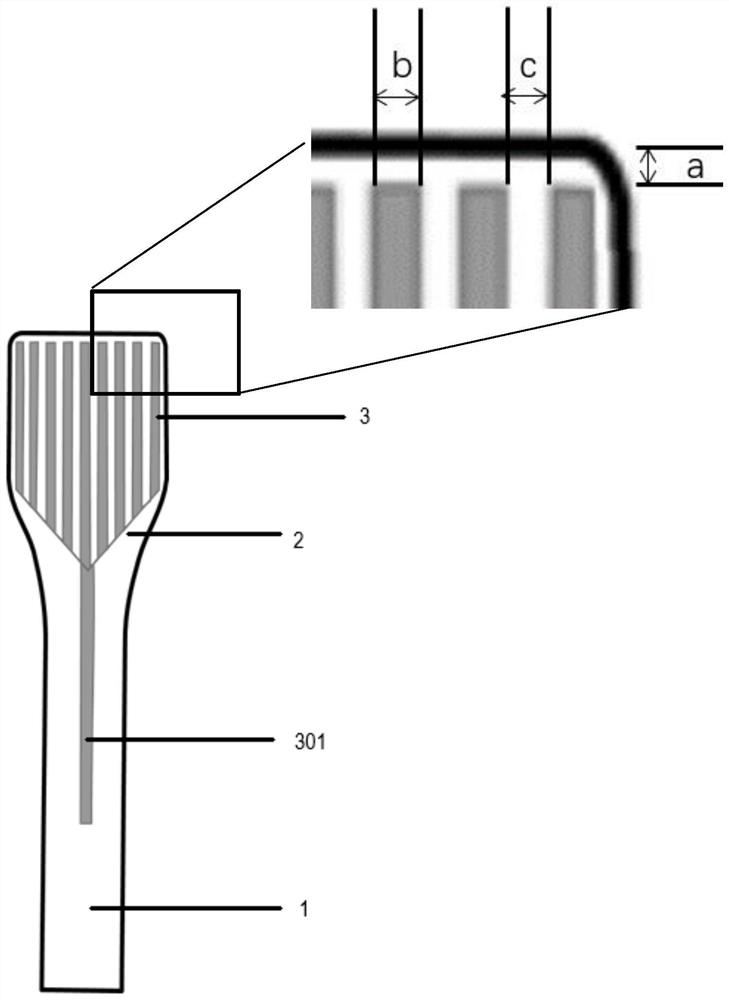

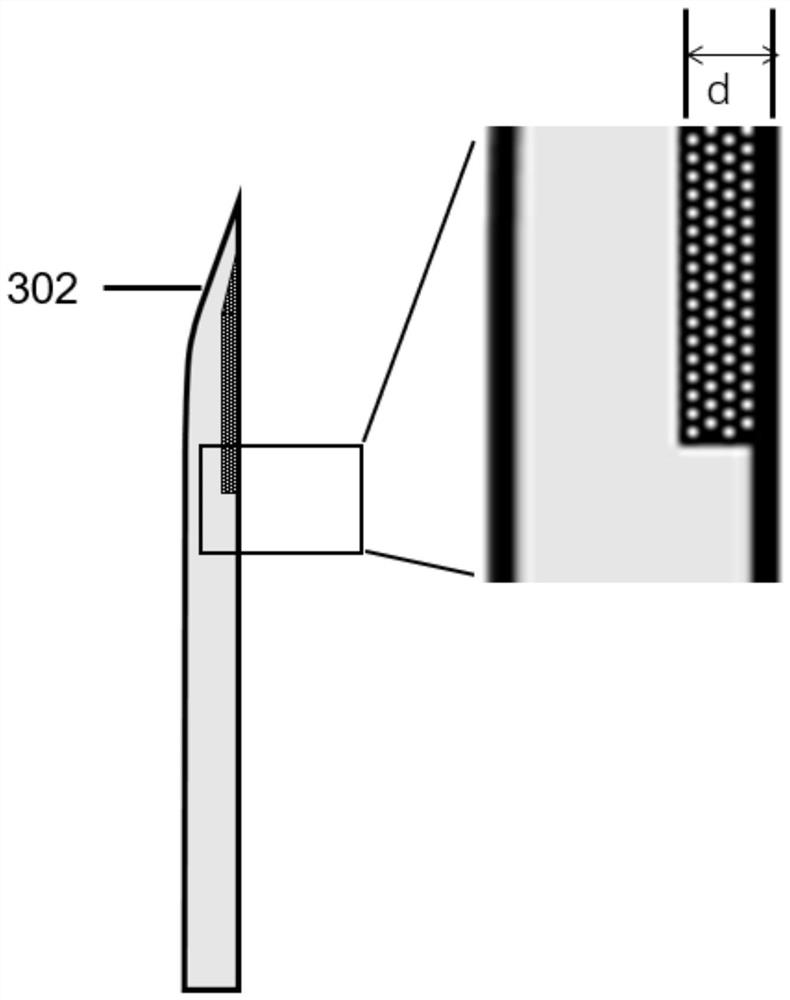

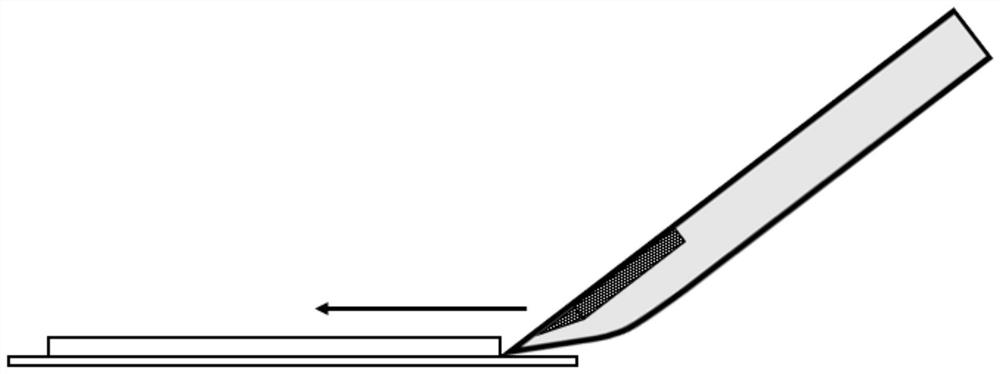

[0058] S1. Prepare cleaning tools with multiple microchannels on the surface, such as figure 1 As shown, the cleaning tool comprises a handle (1), a bottom plate (2) and a micro-channel (3) formed on the upper surface of the bottom plate; the top end of the bottom plate is connected with the handle, and the upper surface and the lower surface of the bottom plate are connected by an inclined plane (302) to form At the bottom end of the bottom plate, the upper surface of the bottom plate forms an acute angle with the inclined plane;

[0059] The bottom end of the microchannel is a plurality of channels parallel to each other and perpendicular to the inclined plane, and the top end is merged into a main channel (301);

[0060] The distance between the bottom end of the microchannel and the bottom end of the bottom plate (a) is 0.5mm, and the width (b) of the microchannel is 1.0×10 -1 mm, the microchannel spacing (c) is 1.0×10 -1 mm, the depth (d) of the microchannel on the bott...

Embodiment 2

[0067] S1. Prepare cleaning tools with multiple microchannels on the surface, such as figure 1 As shown, the cleaning tool comprises a handle (1), a bottom plate (2) and a micro-channel (3) formed on the upper surface of the bottom plate; the top end of the bottom plate is connected with the handle, and the upper surface and the lower surface of the bottom plate are connected by an inclined plane (302) to form The bottom end of the bottom plate, the upper surface of the bottom plate and the inclined plane are at 30°;

[0068] The bottom end of the microchannel is a plurality of channels parallel to each other and perpendicular to the inclined plane, and the top end is merged into a main channel (301);

[0069] The width (b) of the microchannel is 1.0×10 -1 mm, the microchannel spacing (c) is 1.0×10 -1 mm, the depth (d) of the microchannel on the bottom surface is 1.0×10 -1 mm.

[0070] S2. Insert an adsorption material into the microchannel of the cleaning tool, and place ...

Embodiment 3

[0076] S1. Prepare cleaning tools with multiple microchannels on the surface, such as figure 1 As shown, the cleaning tool comprises a handle (1), a bottom plate (2) and a micro-channel (3) formed on the upper surface of the bottom plate; the top end of the bottom plate is connected with the handle, and the upper surface and the lower surface of the bottom plate are connected by an inclined plane (302) to form The bottom end of the bottom plate, the upper surface of the bottom plate and the inclined plane are at 30°;

[0077] The bottom end of the microchannel is a plurality of channels parallel to each other and perpendicular to the inclined plane, and the top end is merged into a main channel (301);

[0078] The distance between the bottom end of the microchannel and the bottom end of the bottom plate (a) is 1mm, and the width (b) of the microchannel is 1.0×10 -1 mm, the microchannel spacing (c) is 1.0×10 -1 mm, the depth (d) of the microchannel on the bottom surface is 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com