Method for increasing fire resistance of meta-aromatic polyamide polymer

An aromatic polyamide and polymer technology is applied in the field of improving the flame retardancy of aromatic polyamide polymers, and can solve the problems of unfavorable environmental protection and production safety protection, weakening the flame retardant effect of flame retardants, and decreasing fiber strength. Achieve the effects of being beneficial to environmental protection and production safety protection, increasing glass transition temperature, and improving flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

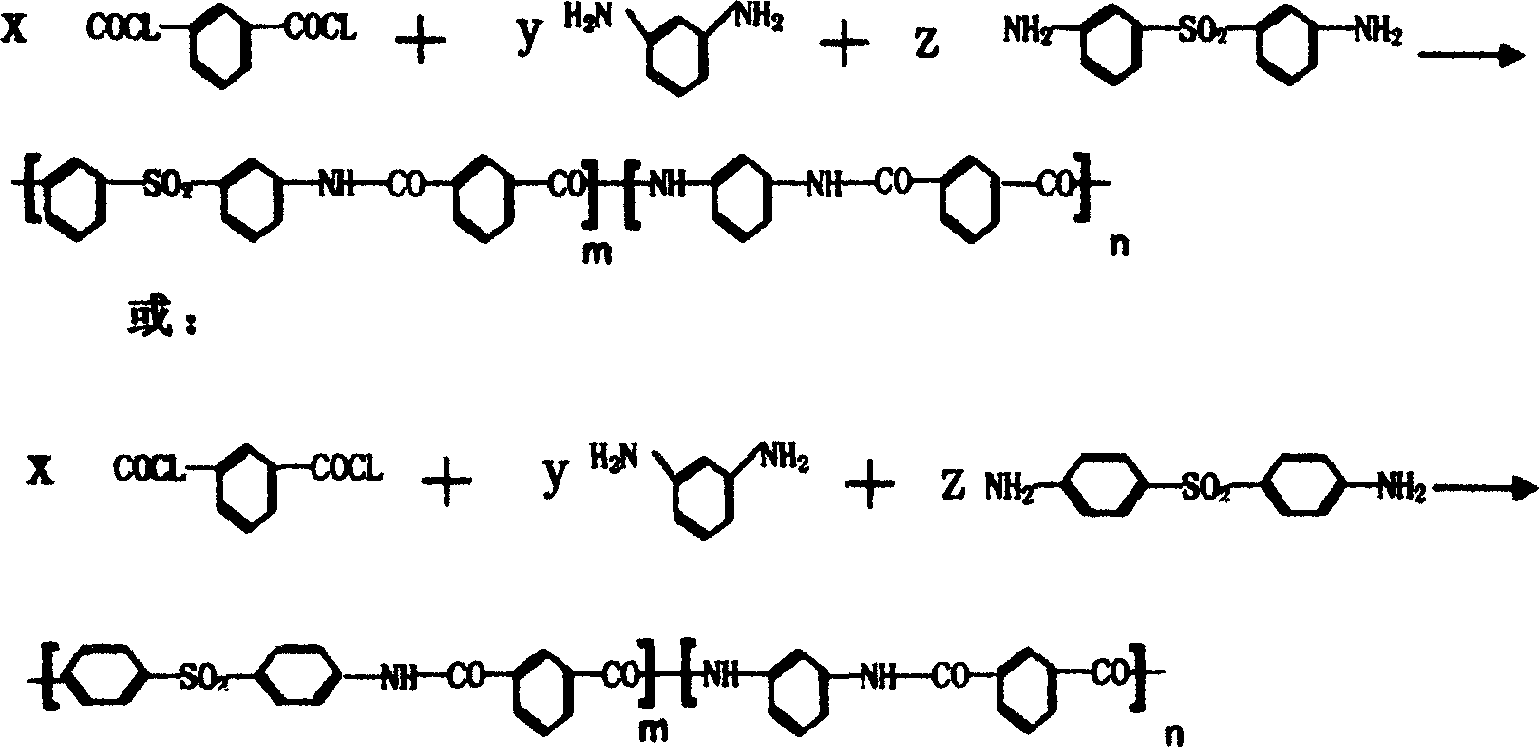

Method used

Image

Examples

example 1

[0015] Dissolve 3.16 kg of m-phenylenediamine and 0.50 kg of 3,3'-diaminodiphenylsulfone in 37.00 kg of dimethylacetamide to form a 9% solution, cool to 0°C, and add in 7 times 6.50 kg of isophthaloyl chloride was subjected to polycondensation reaction under the protection of nitrogen, while controlling the reaction temperature between 0-20°C, and when the apparent viscosity of the solution reached 287Pa·S, the reaction was terminated, and the obtained meta-aromatic The oxygen index of the polyamide polymer is 30, and the glass transition temperature is 247°C.

example 2

[0017] Dissolve 3.10 kg of m-phenylenediamine and 0.6 kg of 3,3'-diaminodiphenylsulfone in 27.13 kg of dimethylacetamide to form a 12% solution, cool to 0°C, and add in 7 times 6.21 kg of isophthaloyl chloride was subjected to polycondensation reaction under the protection of nitrogen, and the reaction temperature was controlled between 0-20°C. When the apparent viscosity of the solution reached 259Pa·S, the reaction was terminated, and the obtained meta-aromatic The oxygen index of the polyamide polymer is 31, and the glass transition temperature is 247°C.

example 3

[0019] Dissolve 2.71 kg of m-phenylenediamine and 1.20 kg of 3,3'-diaminodiphenyl sulfone in 35.20 kg of dimethylacetamide to form a 10% solution, cool to 0°C, and add in 8 times 6.05 kg of isophthaloyl chloride was subjected to polycondensation reaction under the protection of nitrogen, and the reaction temperature was controlled between 0-40°C. When the apparent viscosity of the solution reached 253Pa·S, the reaction was terminated, and the obtained meta-aromatic The oxygen index of the polyamide polymer is 34, and the glass transition temperature is 240°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com