Preparation of carbon nanotube-organic solvent fluid dispersion

A carbon nanotube and organic solvent technology, which is applied in the field of dispersing carbon nanotubes, can solve the problems of destroying the surface structure of carbon nanotubes, large amount of solvent, etc., and achieves the effects of simple process, excellent dispersion effect and long time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

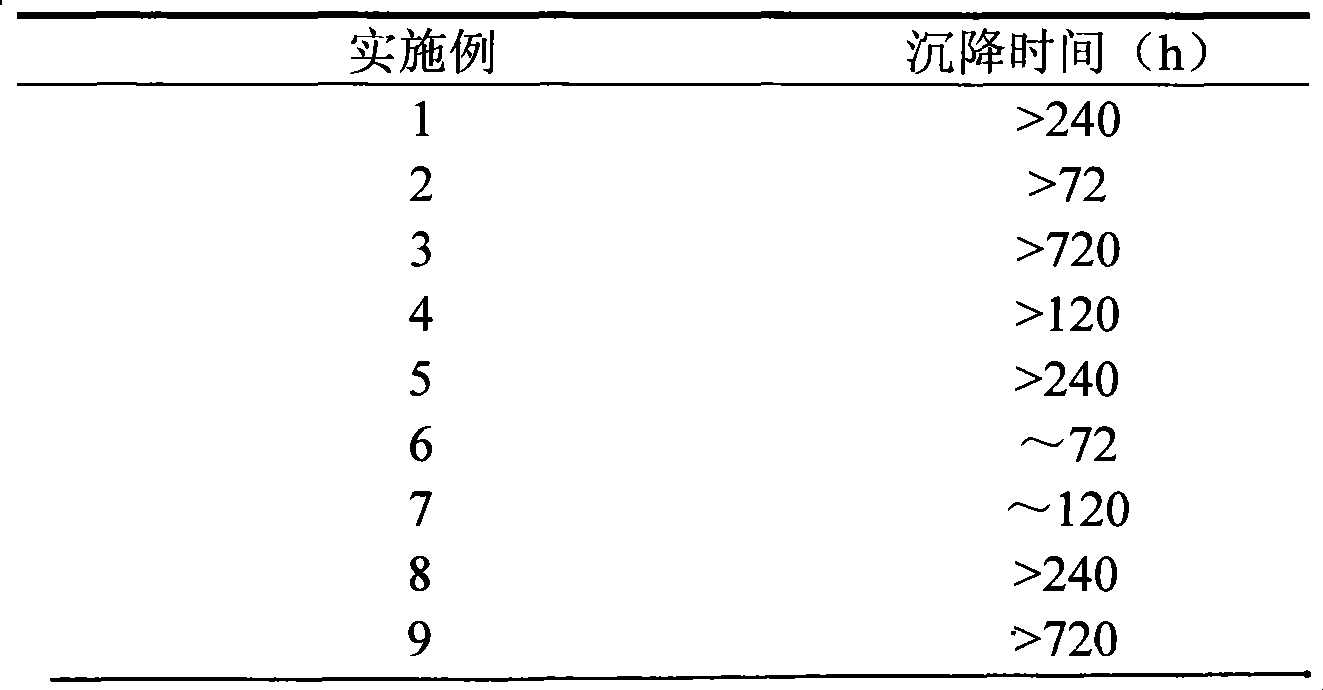

[0018] 0.1 g of multi-walled carbon nanotubes was added to 100 mL of N,N-dimethylformamide (DMF) solution of phthalylated chitosan (PhthCS) prepared at a concentration of 15%. The prepared suspension was placed in an ultrasonic reactor and subjected to ultrasonic treatment for 15 min; the ultrasonic-treated suspension was centrifuged at a centrifugation rate of 1500 r / min, and the supernatant was taken. It is the carbon nanotube-organic solvent dispersion. According to the settling time test, the carbon nanotube-organic solvent dispersion was still stable after being placed for 240 hours, and no settling occurred. The settling time test results of the carbon nanotube-organic solvent dispersion are shown in Table 1.

[0019] Table 1

[0020]

Embodiment 2

[0022] 0.2 g of concentrated sulfuric acid acidified surface-treated carbon nanotubes were added to a prepared 20% concentration of 100 mL of benzoylated chitosan (BCS) in N, N-dimethylacetamide (DMAC) solution. The prepared suspension was put into an ultrasonic reactor, and subjected to ultrasonic treatment for 10 min; the ultrasonic-treated suspension was centrifuged at a centrifugal rate of 2500 r / min, and the supernatant was taken. It is the carbon nanotube-organic solvent dispersion. The settling time test results of the carbon nanotube-organic solvent dispersion are shown in Table 1.

Embodiment 3

[0024] Add 1.2g of nitric acid mixed acid (nitric acid:sulfuric acid ratio 3:1) to acidify the surface-treated carbon nanotubes into 100mL of phthalylated chitosan (PhthCS) with a concentration of 20%. sulfone (DMSO) solution. The prepared suspension was placed in an ultrasonic reactor for ultrasonic treatment for 60 min; the ultrasonically treated suspension was centrifuged at a centrifugation rate of 5000 r / min, and the supernatant was taken. It is the carbon nanotube-organic solvent dispersion. The settling time test results of the carbon nanotube-organic solvent dispersion are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com