Prefabricated linear control method matched with prefabricated bridge deck slab and storage medium

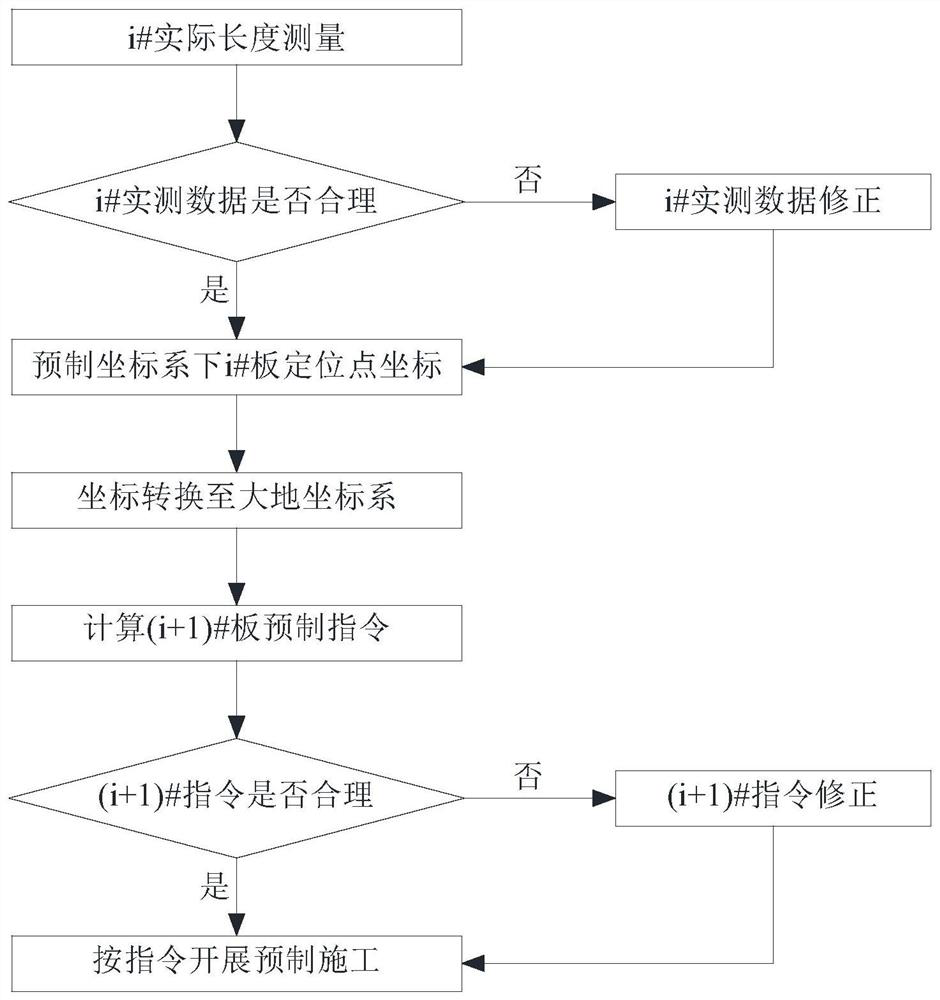

A linear control, prefabricated bridge technology, applied in the field of bridge engineering, can solve the problems of poor applicability, complex data measurement and error correction methods, and high construction costs, to simplify the data measurement and error correction process, measurement and error correction. The process is simple and easy to operate, and the effect of improving the control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

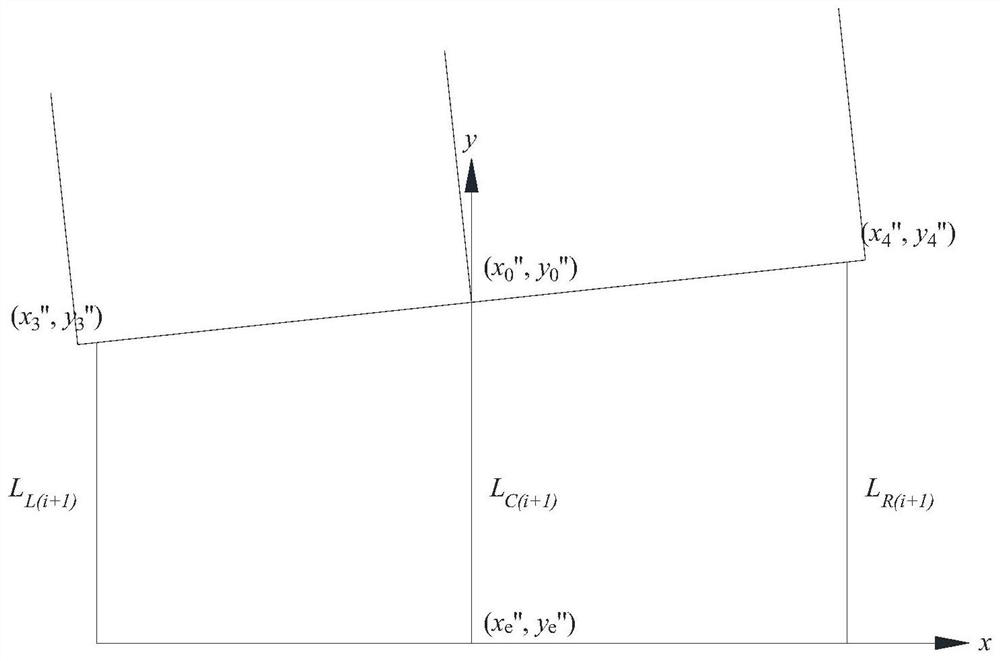

[0087] In this embodiment, through the matching prefabrication of the pre-sequence block segment, the positioning point (x 0(i-1) ',y 0(i-1) '), (x 3(i-1) ',y 3(i-1) '), (x 4(i-1) ',y 4(i-1) ') The coordinates are (500898.6159, 3394958.9610), (500893.7372, 3394955.2578), (500903.4946, 3394962.6643) respectively.

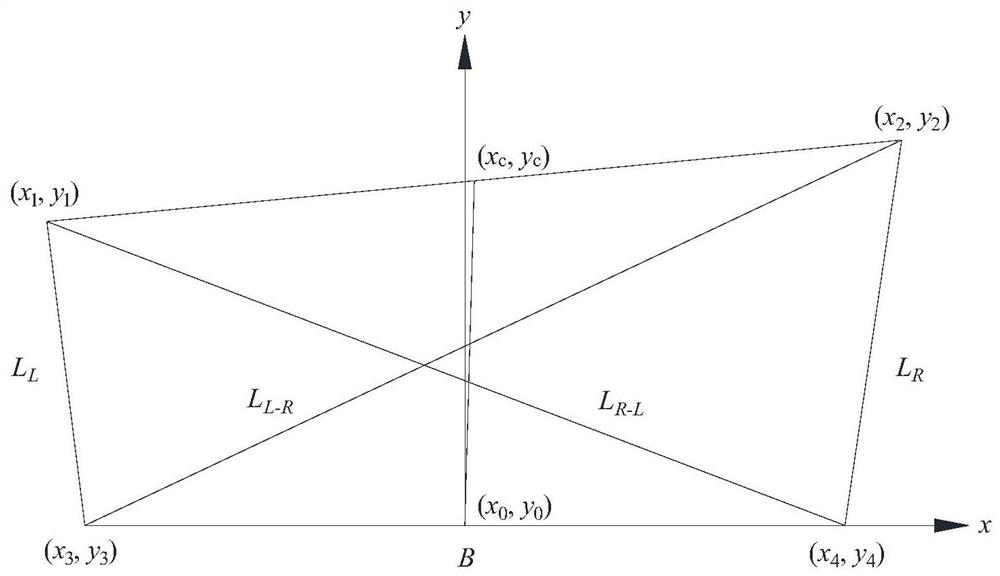

[0088] Through measurement, the actual prefabricated length of the i# slab is obtained: the slab width B on the side of the fixed end mold = 12.264m, the length of the left line of the bridge deck L Li =3.415m, central axis length L Ci =3.420m, the length of the right line board L Ri = 3.432m and the length of the two diagonals L R-Li =12.718m, L L-Ri = 12.722m.

[0089] Check the rationality of the measured data of the i# board, L C =3.420mL +L R ) / 2=3.424m, indicating that the middle of the matching end is concave, which does not affect the prefabricated line shape and does not need to be corrected.

[0090] refer to figure 2 , taking the side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com