Method for analyzing citric acid in stainless steel electrolytic coloring liquid

An electrolytic coloring and analysis method technology, applied in the fields of material science and analytical chemistry, can solve the problems of incomplete color reproducibility and uniformity of colored films, inability to accurately analyze citric acid content, inaccurate analysis of citric acid, etc. The effect of small error, small analysis error and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

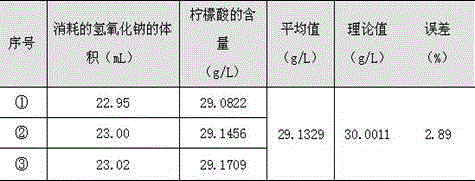

[0019] Example 1 To analyze the stainless steel electrolytic coloring solution using the existing analysis method, take 5 mL of the stainless steel electrolytic coloring solution in a 250 mL Erlenmeyer flask, add 30 mL of water, 3 drops of phenolphthalein indicator, and titrate to red with sodium hydroxide standard solution , repeated parallel measurement 3-5 times. The test results are shown in Table 1 below.

[0020] Table 1: Analysis results of citric acid content in stainless steel electrolytic coloring solution by existing analysis methods

[0021]

Embodiment 2

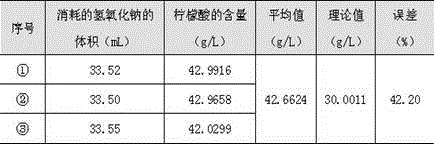

[0022] Embodiment 2 Analytical method of the present invention is to the analysis of stainless steel electrolytic coloring liquid, gets 5mL stainless steel electrolytic coloring liquid in the Erlenmeyer flask of 250mL, adds water 20mL, adds bromothymol blue indicator, titrates with sodium hydroxide standard solution to Pure green, repeat the parallel measurement 3-5 times, and record the data. The test results are shown in Table 2 below.

[0023] Table two: analytical method of the present invention is to the analysis result of citric acid content in stainless steel electrolytic coloring solution

[0024]

[0025] By analyzing the content of citric acid in the stainless steel electrolytic coloring solution through the results of concrete implementation 1 and implementation 2, the error of the analysis method of the present invention is obviously much smaller than the error of the existing analysis method at present.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com