Aluminum-plastic co-extrusion corner connector filling diversion trench opening structure

A corner code, aluminum-plastic technology, used in building components, building structures, corner joints/edge joints, etc., can solve problems such as reducing the connection strength of doors and windows, poor adhesion between aluminum lining and plastic, and inclined corner code installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing:

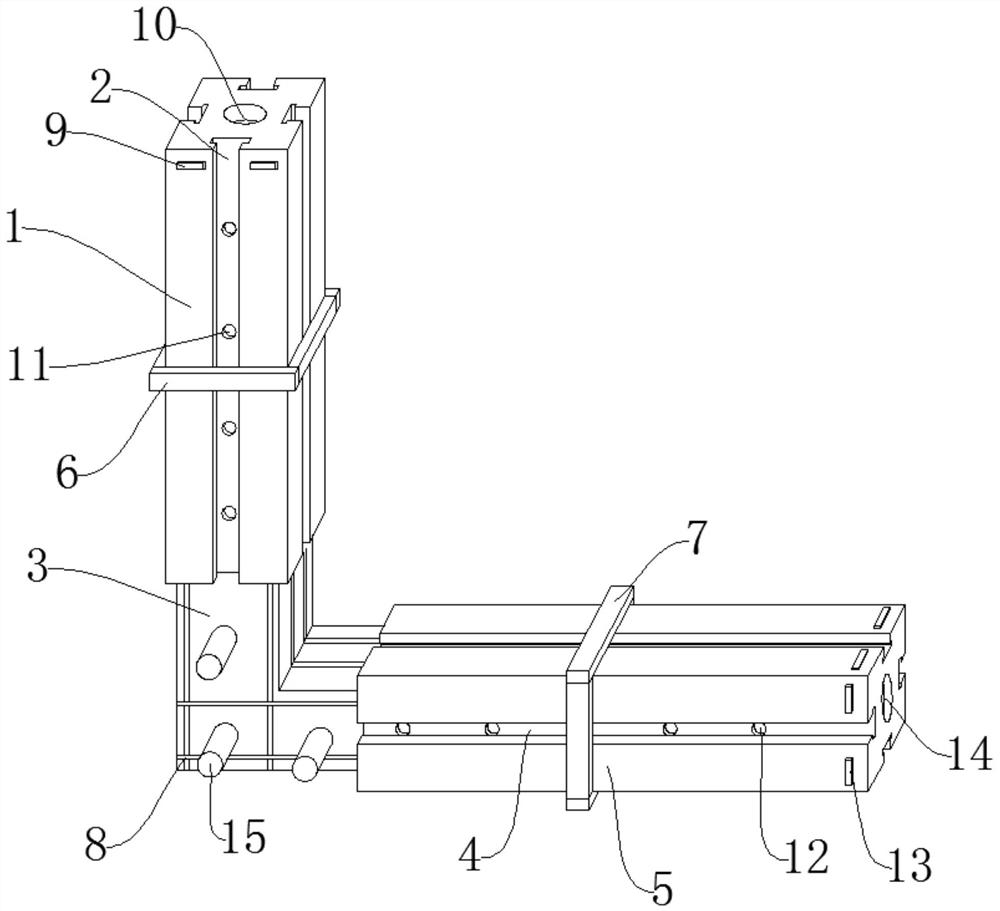

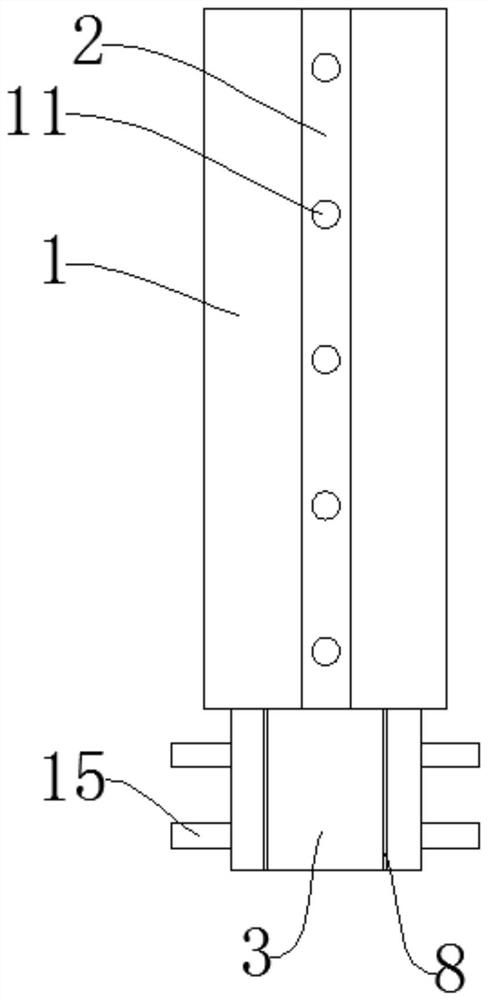

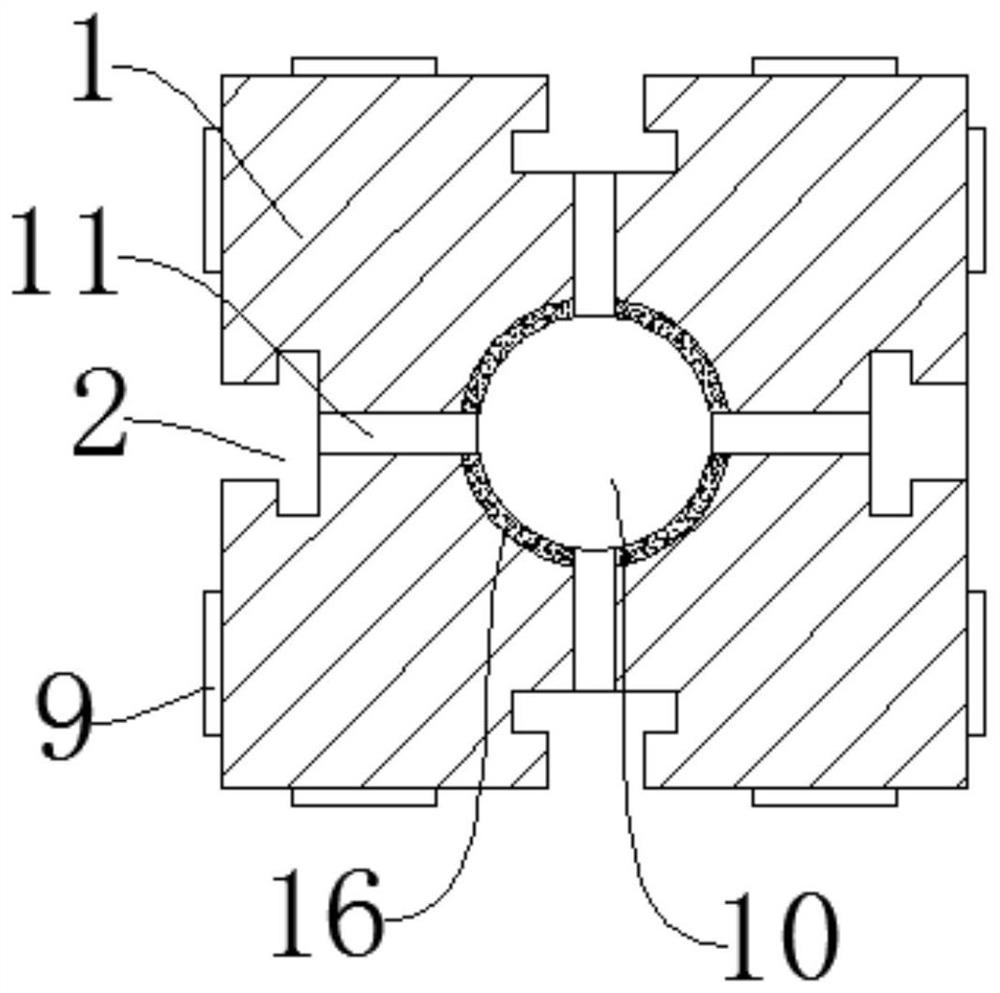

[0038] Such as Figure 1-Figure 5 As shown, an aluminum-plastic co-extruded corner code fills the diversion groove structure, including an L-shaped connecting block, a through hole 1 and a positioning block 1, the upper end of the L-shaped connecting block 3 is provided with a connecting piece 1, and the L-shaped Type connection block 3 one side is provided with connector two 5, described connector one 1 is provided with described through hole one 10, and described connector one 1 is provided with T-shaped groove one 2 on the side wall around, and described T The two sides of the type groove one 2 are provided with a positioning block one 9, and the inside of the T-shaped groove one 2 is provided with a connecting groove one 11, the connecting groove one 11 communicates with the through hole one 10, and the middle part of the connecting piece one 1 A reinforcing rib 6 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com