A kind of hydrogenation machine fusion control method and system

A technology that integrates control and hydrogenation machines, and is applied in container filling methods, container discharge methods, motor vehicles, etc., and can solve problems such as the decline in filling efficiency, the temperature rise of hydrogen storage bottles, and potential safety hazards, achieving both high efficiency and high efficiency. The effect of fast filling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

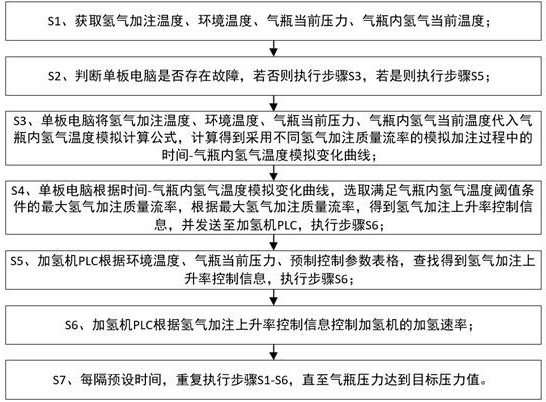

[0051] refer to figure 1 As shown, the present embodiment provides a method for controlling fusion of a hydrogenation machine, comprising the steps of:

[0052] S1. Obtain the hydrogen filling temperature, the ambient temperature, the current pressure of the gas cylinder, and the current temperature of the hydrogen in the gas cylinder (it should be noted that the hydrogen filling temperature and the ambient temperature are basically unchanged during one hydrogen filling process, so for these two The data may not be acquired in real time, but can be acquired only once at the beginning of betting);

[0053] S2, determine whether the single-board computer is faulty, if otherwise, perform step S3, and if so, perform step S5;

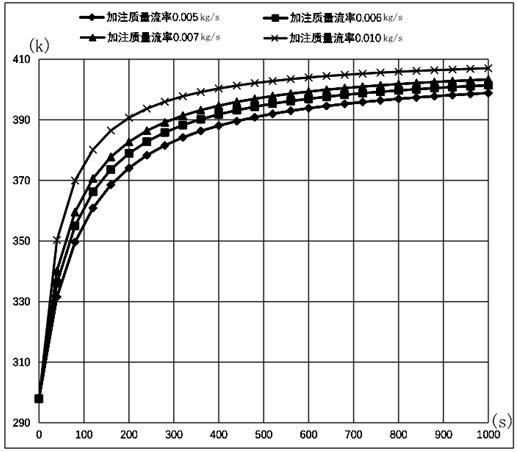

[0054] S3. The single-board computer substitutes the hydrogen filling temperature, the ambient temperature, the current pressure of the gas cylinder, and the current temperature of the hydrogen in the gas cylinder into the simulation calculation formula of ...

Embodiment 2

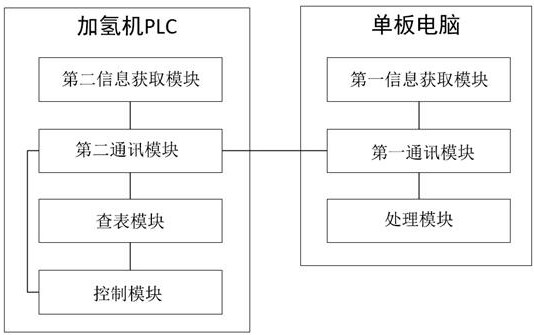

[0116] refer to image 3 As shown, this embodiment provides a hydrogenation machine fusion control system, which is based on the hydrogenation machine fusion control method described in the first embodiment, and includes a connected hydrogenation machine PLC and a single-board computer, and the single-board computer includes a first an information acquisition module, a processing module, and a first communication module, and the hydrogenation machine PLC includes a second information acquisition module, a table lookup module, a second communication module, and a control module;

[0117] The first information acquisition module and the processing module are respectively connected with the first communication module; the second information acquisition module and the table lookup module are respectively connected with the second communication module; the second communication module and the table lookup module are respectively connected with the control module; the first communicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com