Device for building dynamic negative pressure by using interlayer gun

A negative pressure device and interlayer technology, applied in the field of oilfield machinery, can solve the problem that the interlayer gun is not used and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical scheme of the present invention will be further described below in conjunction with accompanying drawing, but should not be construed as limiting the present invention:

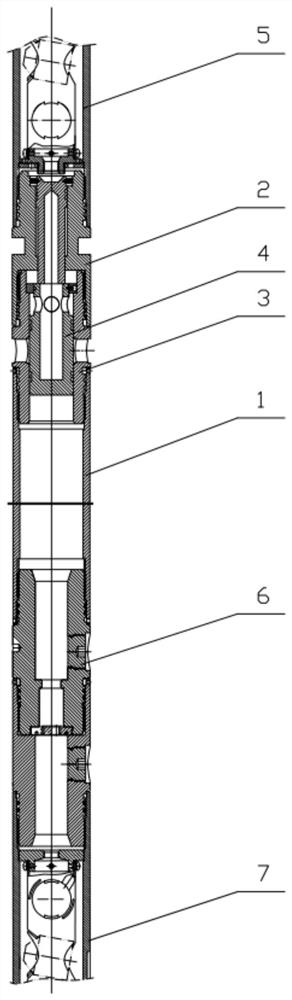

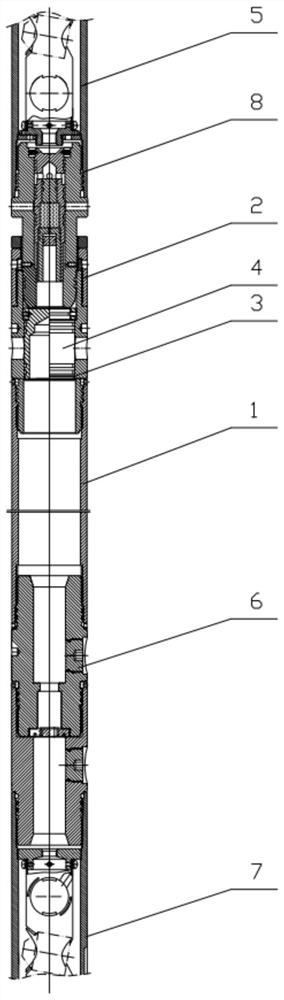

[0015] A dynamic negative pressure device constructed by using an interlayer gun, comprising an interlayer gun 1 . A negative pressure cabin door device 2 is added to one or both ends of the interlayer gun 1. The negative pressure cabin door device 2 includes a main body 3 and a slidable negative pressure piston 4. There are four holes on the side wall of the main body 3. There are four liquid inlet holes, and the negative pressure piston 4 is located in the main body 3 and blocks the four liquid inlet holes. When the negative pressure piston 4 is pushed into the negative pressure gun body under the pressure of the well fluid, the liquid inlet channel is opened, and the well fluid flows into the inner cavity of the negative pressure gun through the liquid inlet channel, causing the loss o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com