Light weight foam concrete capable of adsorbing mass decoration pollutants

A lightweight foam and pollutant technology, applied in the field of lightweight foam concrete, can solve the problems of formaldehyde content rebound and poor treatment effect, and achieve the effect of promoting absorption and decomposition, and improving absorption and decomposition capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

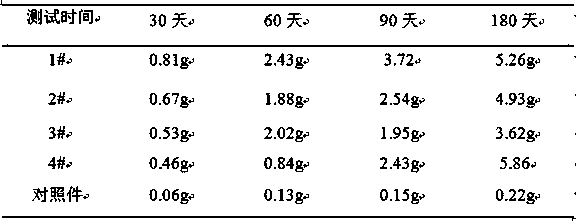

Examples

Embodiment 1

[0032] Example 1 Preparation of 1# lightweight foam concrete capable of absorbing a large amount of decoration pollutants

[0033] 1. Preparation of non-closed cement foaming agent

[0034] Weigh 15g of sodium α-alkenyl sulfonate, 0.5g of propylene glycol alginate, and 2.5g of modified silicone resin polyether microemulsion FM550 in a beaker, then add 2000mL of water and stir evenly to obtain the required cement foaming agent Emulsion spare.

[0035]2. Preparation of sodium perborate particles with protective film

[0036] Mix 200-mesh sodium perborate and hydroxyethyl starch solution with a degree of substitution of 0.1 at a mass ratio of 1:0.5, then add 1% of alginate by mass, stir quickly and evenly, and dry in vacuum to obtain a protective film sodium perborate particles.

[0037] 3. Compound modified polyol

[0038] Select acornic acid with a molecular weight of 1000Da, 1,3,4,6-tetragalloyl-2-β-D-glucose and diflavanol, and compound the three according to the mass rat...

Embodiment 2

[0042] Example 2 Preparation of 2# lightweight foam concrete capable of absorbing a large amount of decoration pollutants

[0043] 1. Preparation of non-closed cement foaming agent

[0044] Weigh 20g of sodium α-alkenyl sulfonate, 1.0g of propylene glycol alginate, and 4.0g of modified silicone resin polyether microemulsion FM550 into a beaker, then add 2000mL of water and stir evenly to obtain the required cement foaming agent Emulsion spare.

[0045] 2. Preparation of peroxide particles with protective film

[0046] Mix the mixture of 400 mesh sodium percarbonate and sodium perborate (mass ratio 1:3) with the hydroxyethyl cellulose solution with a degree of substitution of 0.1 in a mass ratio of 1:0.4, and then add 1.5% seaweed Glue, stir quickly and then dry in vacuum to obtain peroxide particles with protective film.

[0047] 3. Compound modified polyol

[0048] Select acornic acid with a molecular weight of 1500Da, 1,3,4,6-tetragalloyl-2-β-D-glucose and diflavanol, an...

Embodiment 3

[0052] Example 3 Preparation of 3# lightweight foam concrete capable of a large amount of adsorption of decoration pollutants

[0053] 1. Preparation of non-closed cement foaming agent

[0054] Weigh 18g of sodium α-alkenyl sulfonate, 0.75g of propylene glycol alginate, and 3.0g of modified silicone resin polyether microemulsion FM550 into a beaker, then add 2000mL of water and stir evenly to obtain the required cement foaming agent Emulsion spare.

[0055] 2. Preparation of peroxide particles with protective film

[0056] Mix the mixture of 300 mesh sodium percarbonate and sodium perborate (mass ratio 1:3) with the starch acetate solution with a degree of substitution of 0.1 in a mass ratio of 1:0.6, and then add 2.0% alginate by mass ratio to quickly Stir evenly and then vacuum dry to obtain peroxide particles with a protective film.

[0057] 3. Compound modified polyol

[0058] Select acornic acid with a molecular weight of 3000Da, 1,3,4,6-tetragalloyl-2-β-D-glucose and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com