Environmental test cabin

An environmental test and test cabin technology, applied in the field of aero-engine test devices, can solve problems such as easy oil leakage, high construction cost, and complex structure, and achieve the effects of reduced design size, simple driving operation, and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered below.

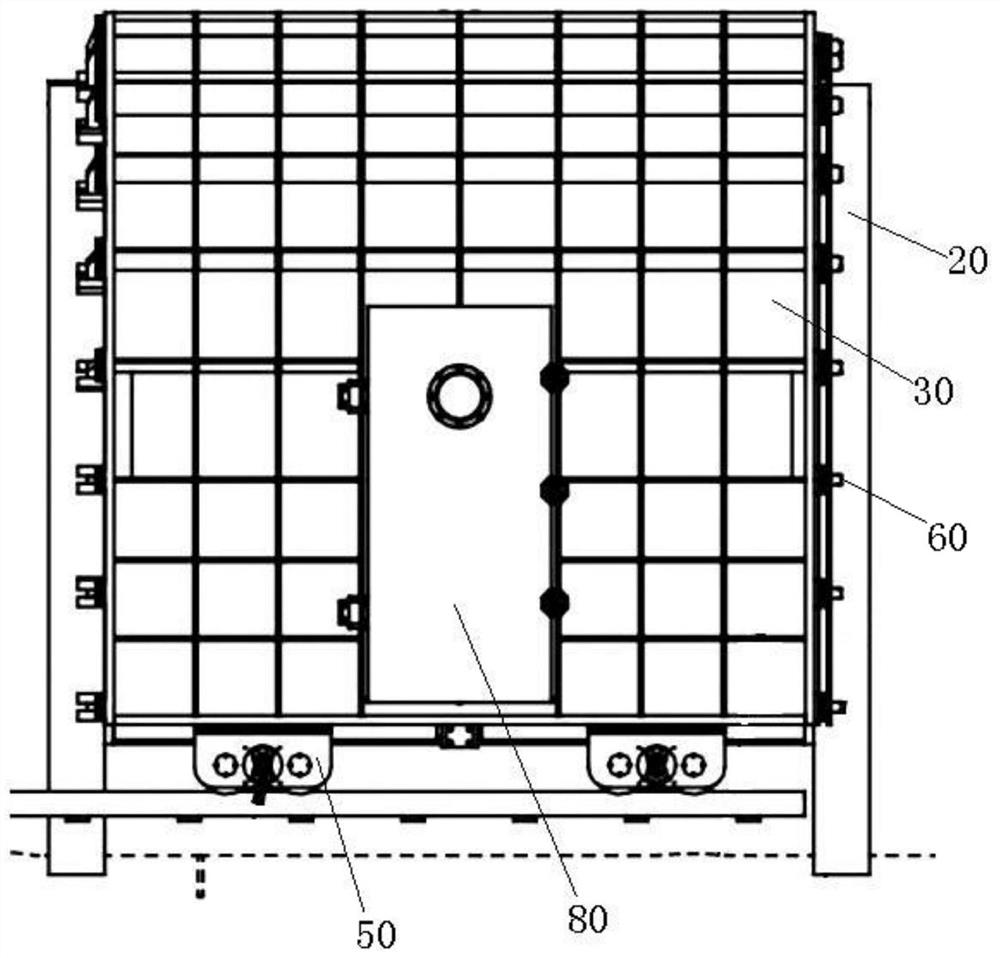

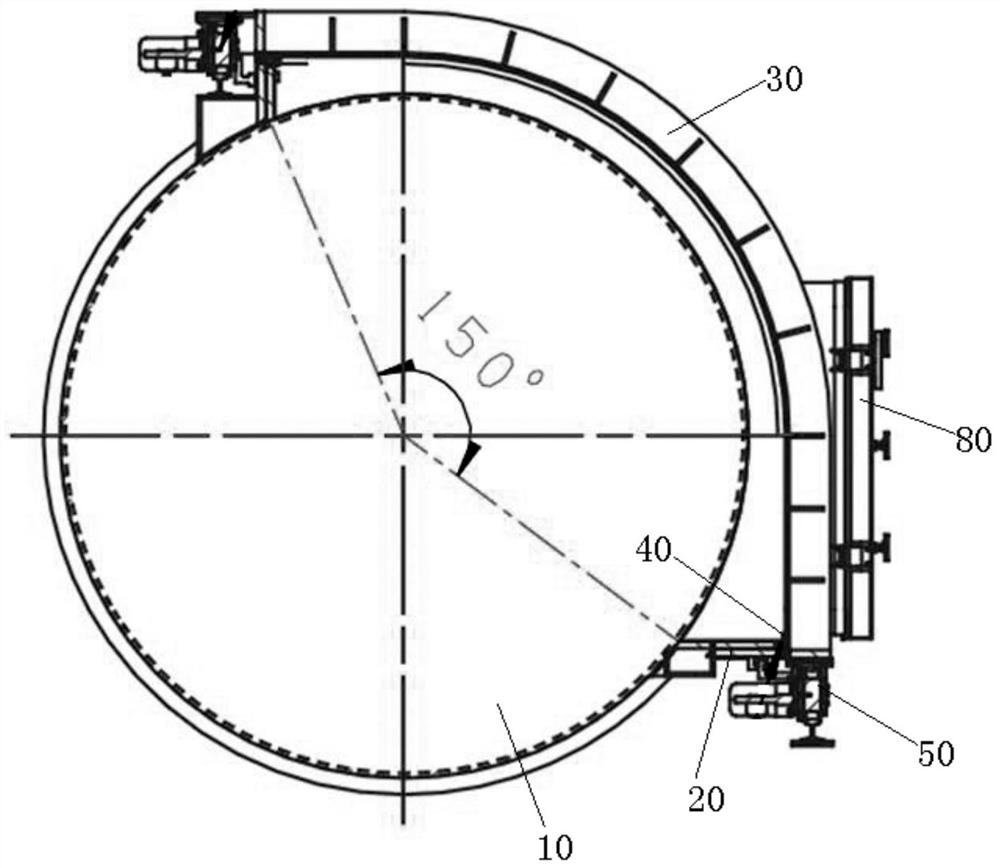

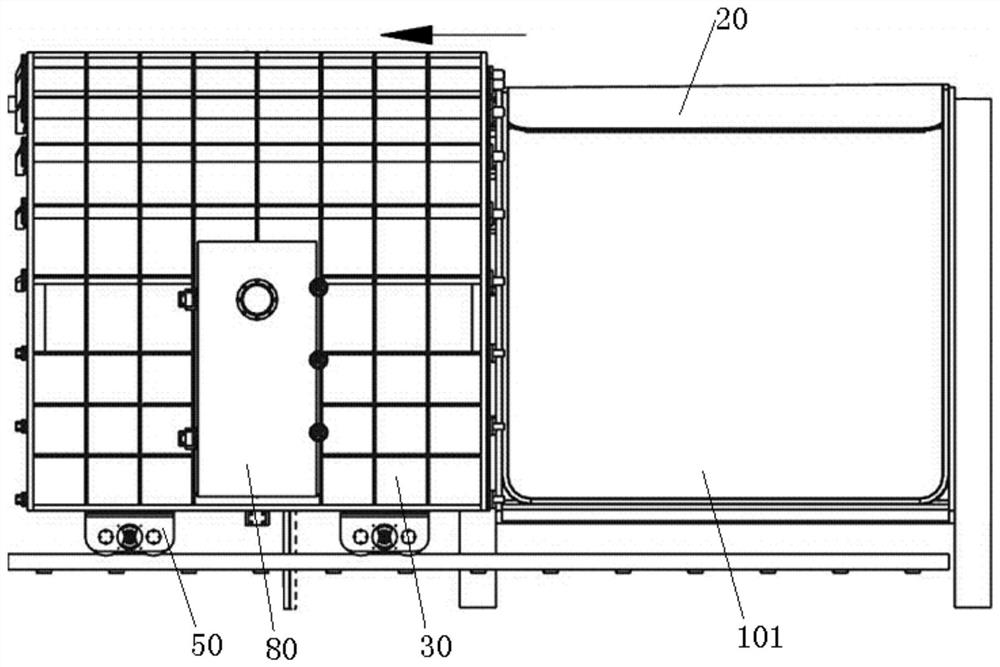

[0032] refer to figure 1 with figure 2 , the preferred embodiment of the present invention provides an environmental test chamber, comprising: a hollow cylindrical test chamber body 10, the test chamber body 10 is arranged on the installation foundation along the horizontal direction, and the wall surface of the test chamber body 10 is provided with a Exit 101, for the machine to be tested and the test equipment to be tested to enter and exit the test cabin body 10. The entrance and exit 101 is provided with a sliding hatch for sealing the entrance and exit 101, the sliding hatch is connected to the test cabin 10, and is arranged to slide horizontally along the axial direction of the test cabin 10 to open or close the test cabin 10 .

[0033]In the environment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com