Non-magnetic multi-pin temperature-resistant pressure-bearing electric connector

A connector and temperature-resistant technology, which is used in the field of non-magnetic multi-pin temperature-resistant electrical connectors, which can solve problems such as failure to meet accurate signal transmission requirements and data deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The value of each component of the present invention and the preparation method are described in further detail by the following examples:

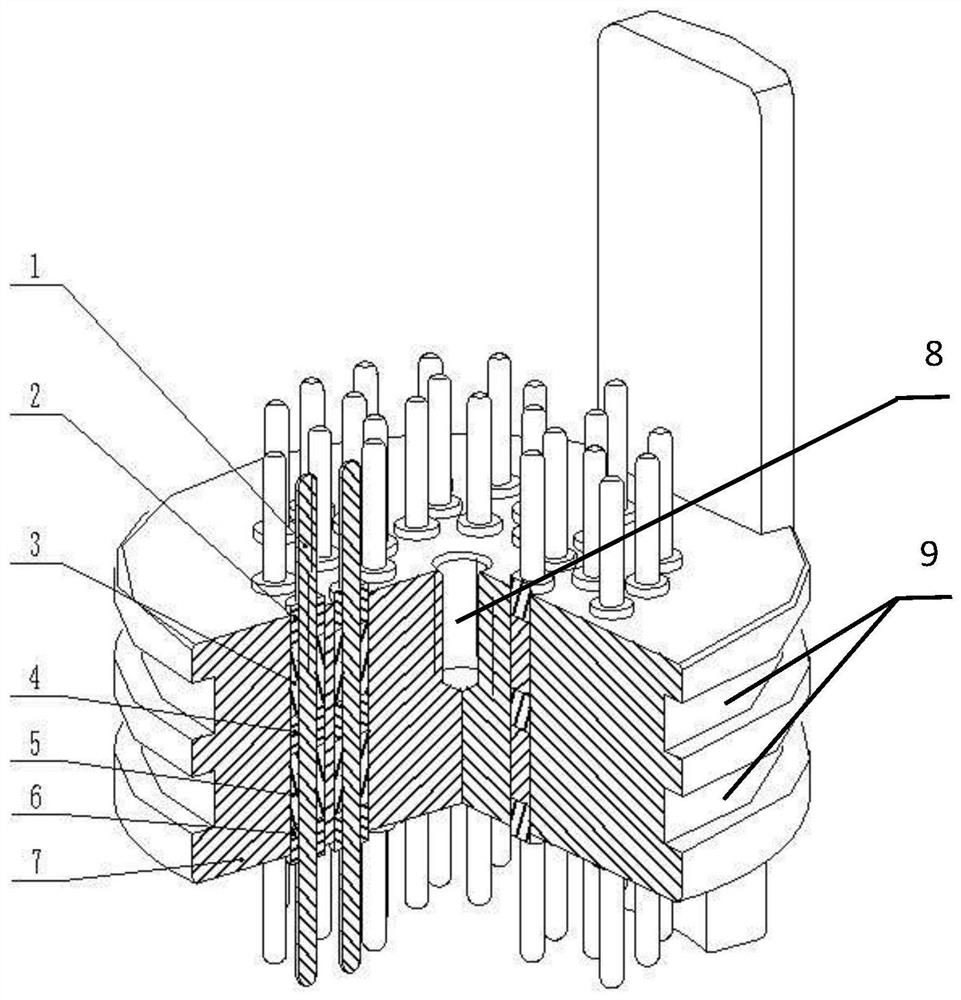

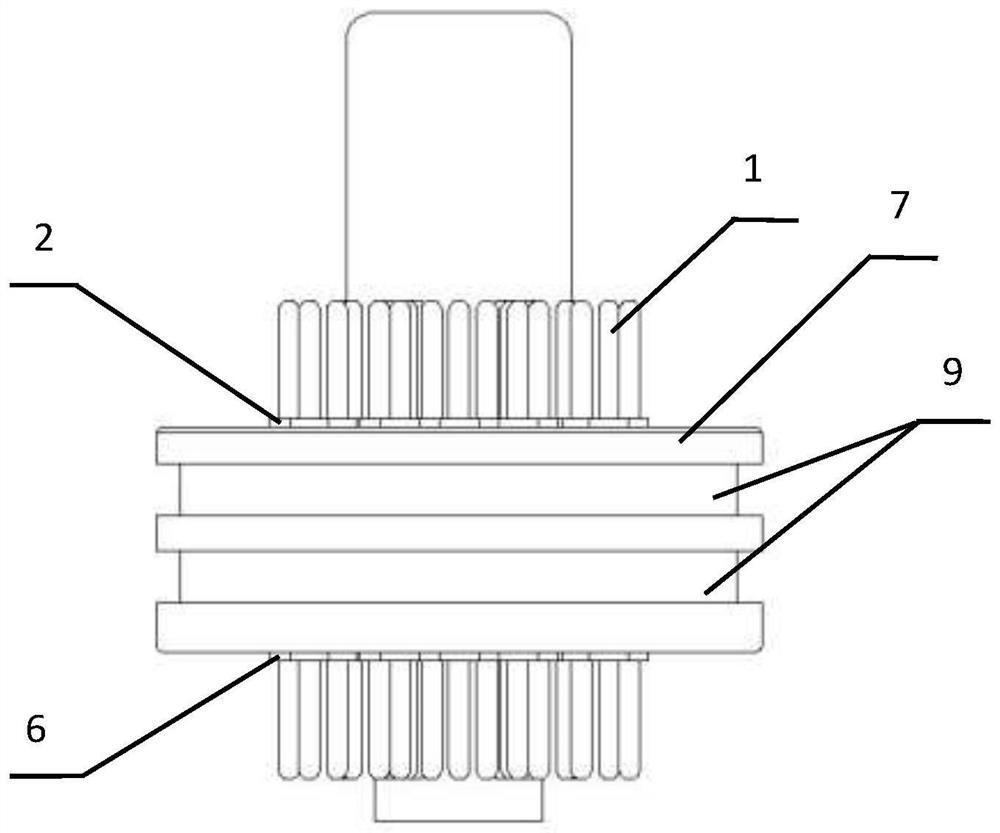

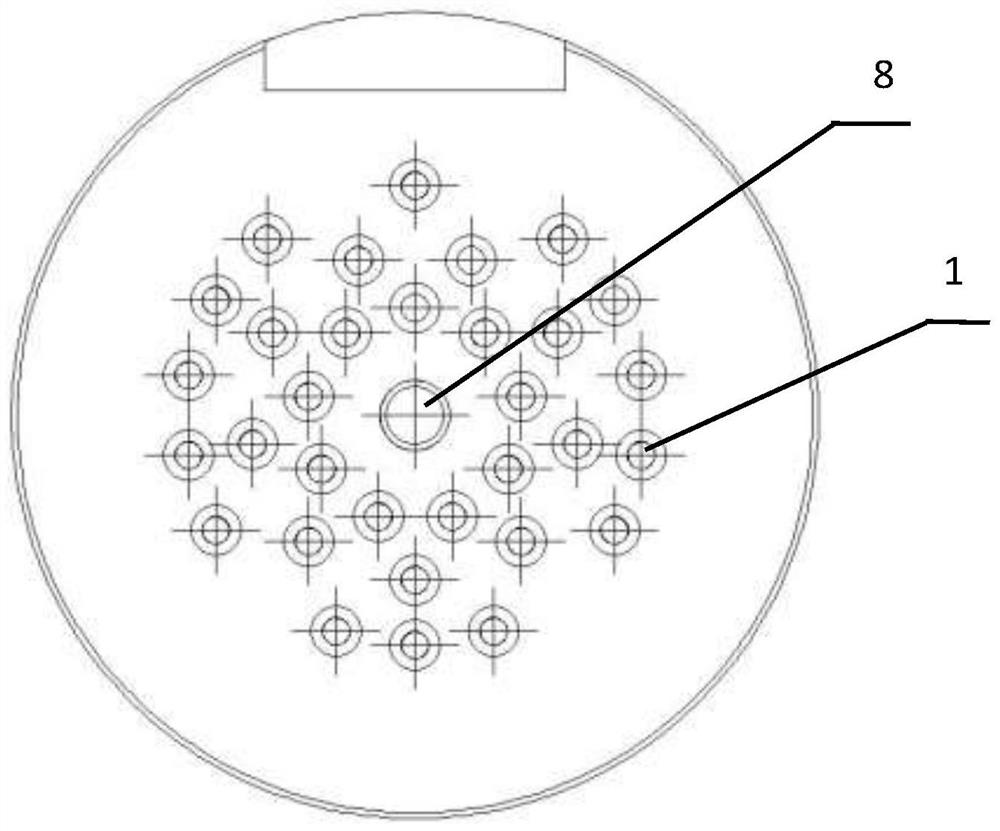

[0026] Such as Figure 1 to Figure 4 As shown, a non-magnetic multi-pin temperature-resistant and pressure-bearing electrical connector includes a shell 7, a number of pins 1 and a plurality of insulators, and a threaded blind hole 8 and a plurality of through holes are provided on the shell 7. The pin 1 is a columnar structure, and each through hole inserts a pin 1. The insulators include the first insulator 2, the second insulator 3, the third insulator 4, the fourth insulator 5 and the fifth insulator 6, and the insulators are all ring structures. It is sleeved between the pin 1 and the inner wall of the through hole, and the pin 1 is insulated from the shell 7 .

[0027] In this embodiment, two concave sealing grooves 9 are provided on the outer surface of the housing 7 .

[0028] In this embodiment, neither the pin 1 nor the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com