Method and device for controlling closing and opening overvoltage suppression of doubly-fed motor stator

A doubly-fed motor and control method technology, which is applied in the direction of AC motor control, emergency protection circuit device, control system, etc., can solve the problems of increasing system maintenance cost and difficulty, unable to achieve real-time detection, etc., so as to avoid impact and enhance function, the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to make the objectives, technical solutions and advantages of the present invention clearer, the technical solutions in the embodiments of the present invention will be described in more detail below in conjunction with the drawings in the embodiments of the present invention.

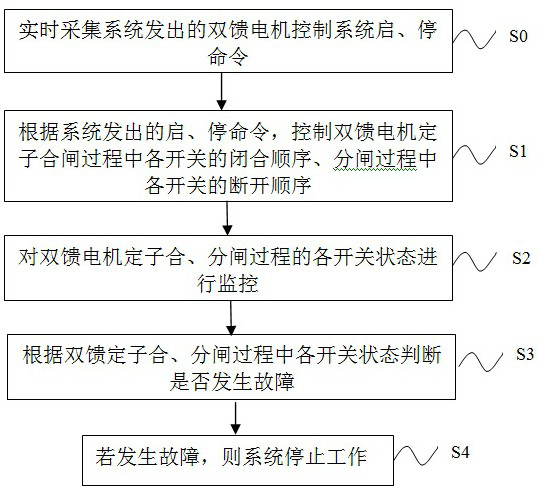

[0059] Aiming at the rotor overvoltage problem caused by the asynchronous closing of the stator of the doubly-fed motor, the embodiment of the present invention provides a control method for suppressing the overvoltage of the stator closing and opening of the doubly-fed motor. The flow chart is as follows figure 1 As shown, the method includes,

[0060] Step S0: start and stop commands of the doubly-fed motor control system issued by the real-time acquisition system.

[0061] Step S1: According to the start and stop commands issued by the system, control the closing sequence of the switches during the closing process of the double-fed motor stator, and the opening sequence of the switch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com