Copper-clad plate clamping system and clamping turnover method

A technology of copper clad laminate and steering wheel, applied in the direction of lifting device, hoisting device, etc., can solve the problems of easy deformation of copper clad laminate, high requirements on the shape of copper clad laminate, and low scope of application, so as to improve the convenience of disassembly and assembly, improve the Ease of use, low angular velocity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

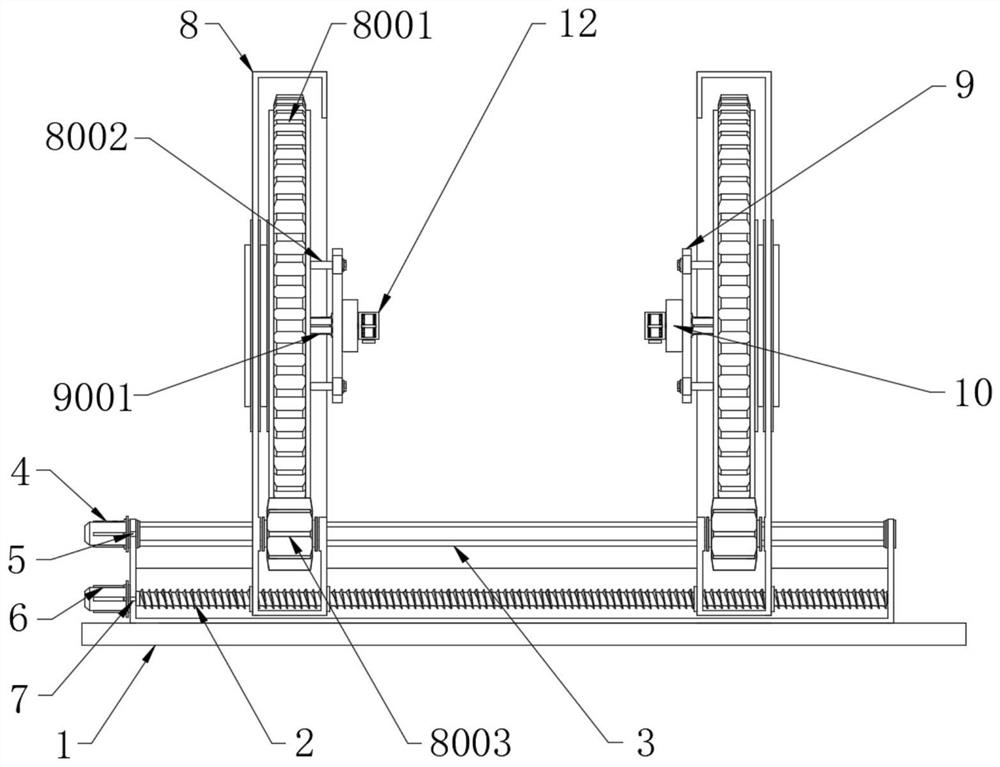

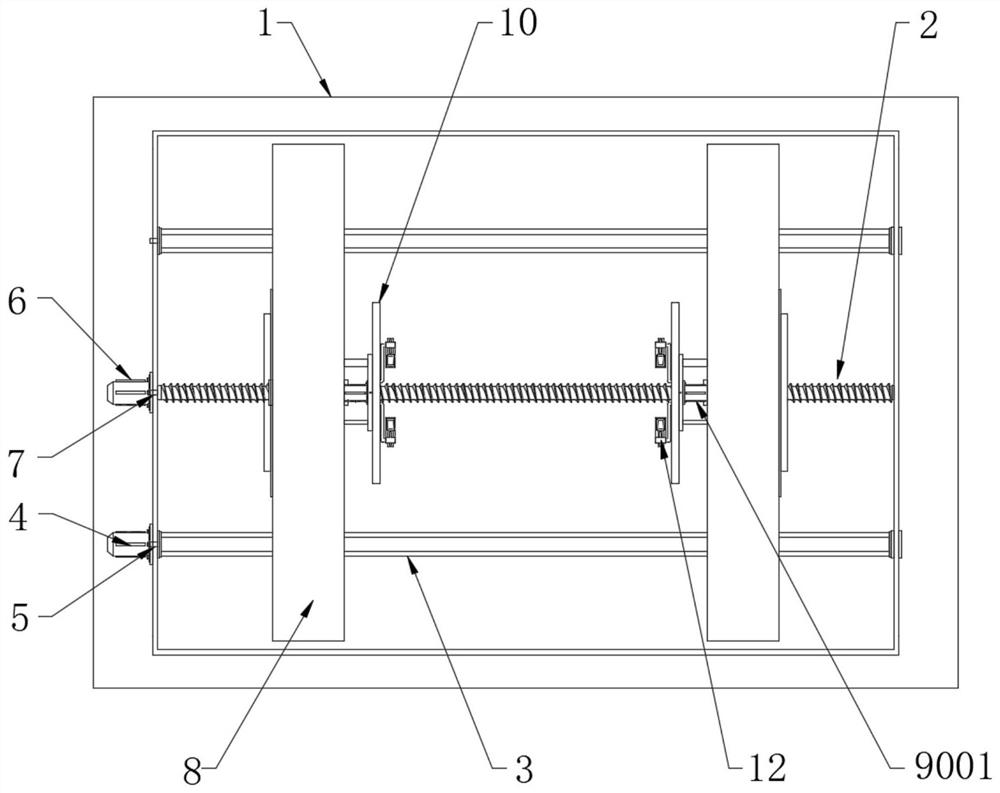

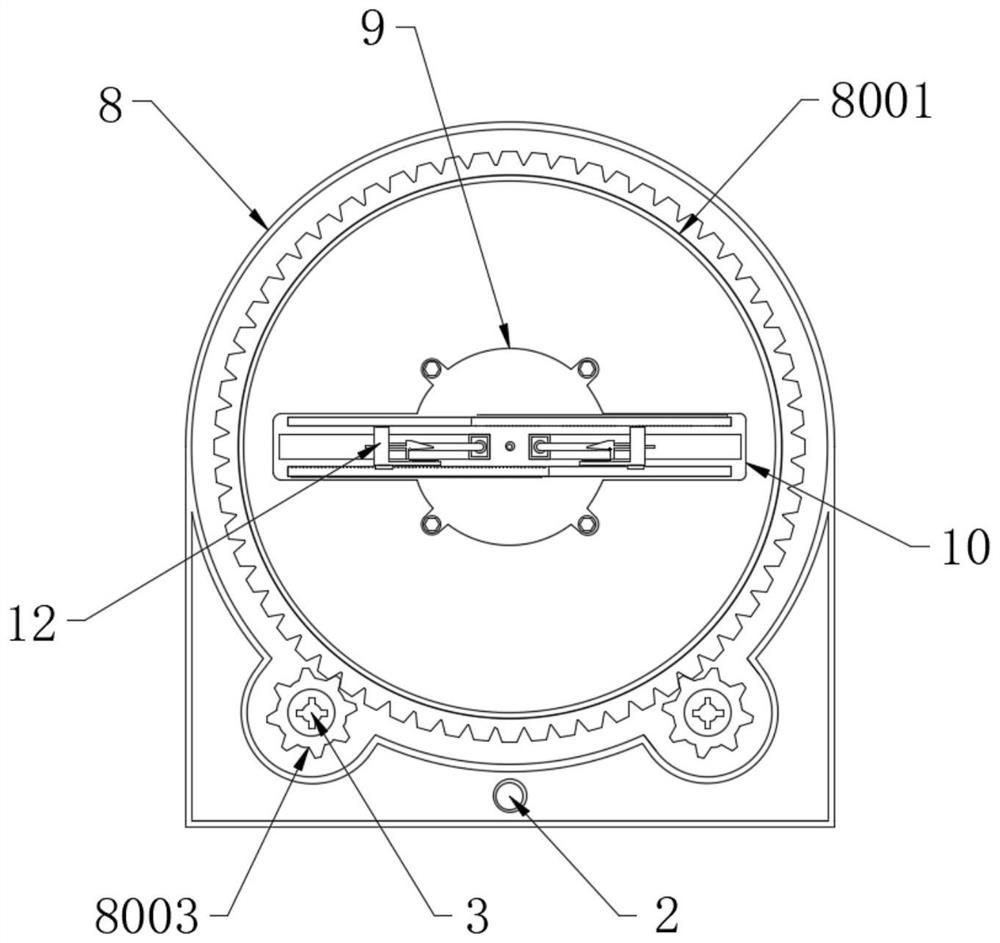

[0035] Please refer to Figure 1 to Figure 11 As shown, it shows the specific structure of a preferred embodiment of the present invention, a heat dissipation structure of an air-conditioning unit, including a base 1, a transmission shaft 3 and a housing 8, the top of the base 1 is a groove structure, and the base The inner lower end of 1 is equipped with a threaded mandrel 2, wherein the threaded mandrel 2 forms a rotating structure with the second motor 6 through the second motor shaft 7, and the second motor 6 is installed on one side of the outer wall of the base 1; the transmission shaft 3 is about The central axis of the base 1 is symmetrically arranged with two, and the two transmission shafts 3 are respectively installed on the inner two ends of the base 1, and the two transmission shafts 3 are parallel to the screw rod 2, and one of the transmission shafts 3 passes through the The first motor shaft 5 and the first motor 4 form a rotating structure, wherein the first m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com