A copper-clad laminate clamping system and clamping and flipping method

A technology of copper-clad laminates and steering wheels, which is applied in hoisting devices, hoisting devices, etc., can solve the problems of easy deformation of copper-clad laminates, low application range, and high requirements on the shape of copper-clad laminates, so as to improve the convenience of disassembly and assembly and improve the use Convenience and the effect of low angular velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

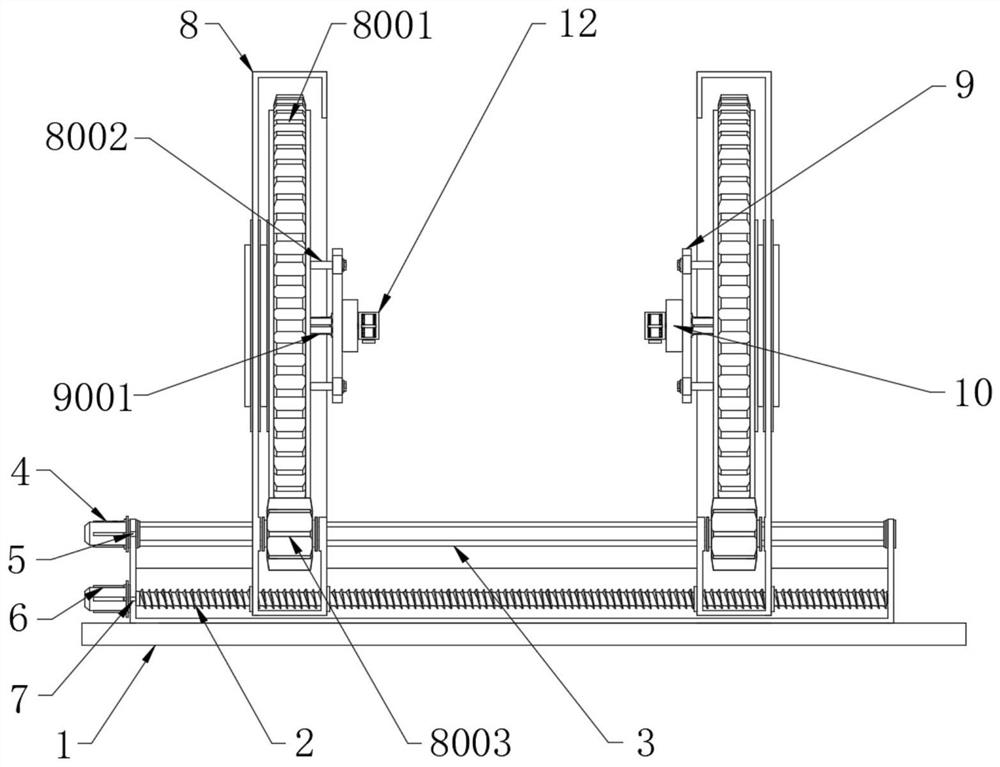

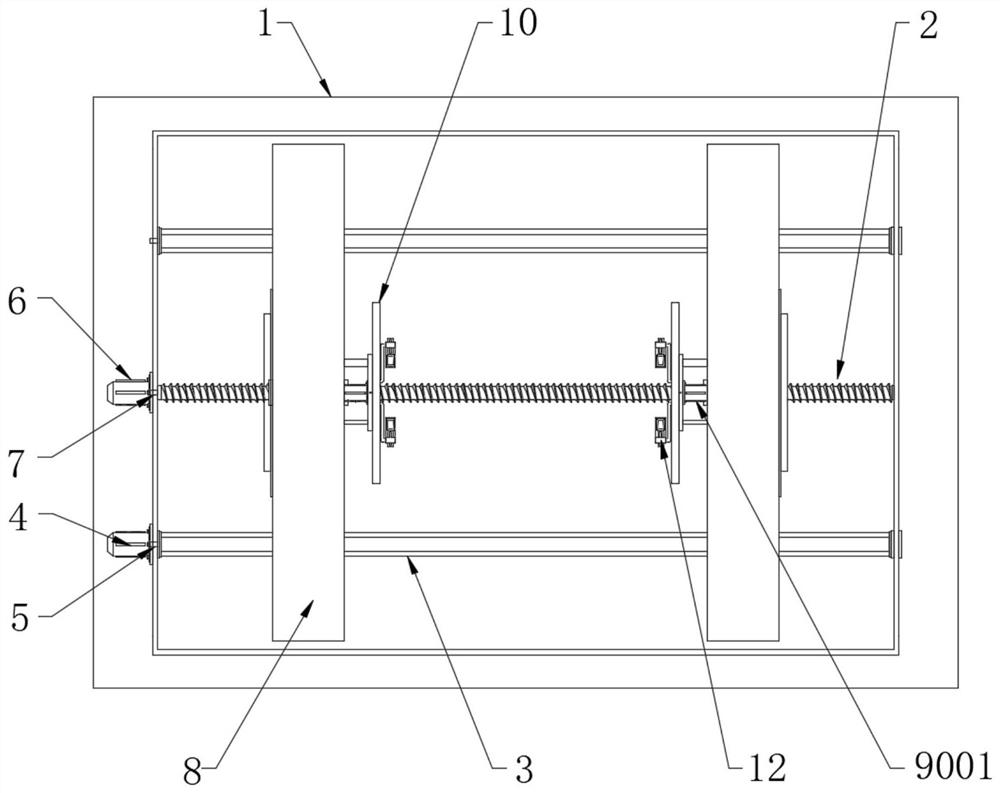

[0035] Please refer to FIG. 1 to FIG. 11, which show the specific structure of the preferred embodiment of the present invention, a kind of air conditioner

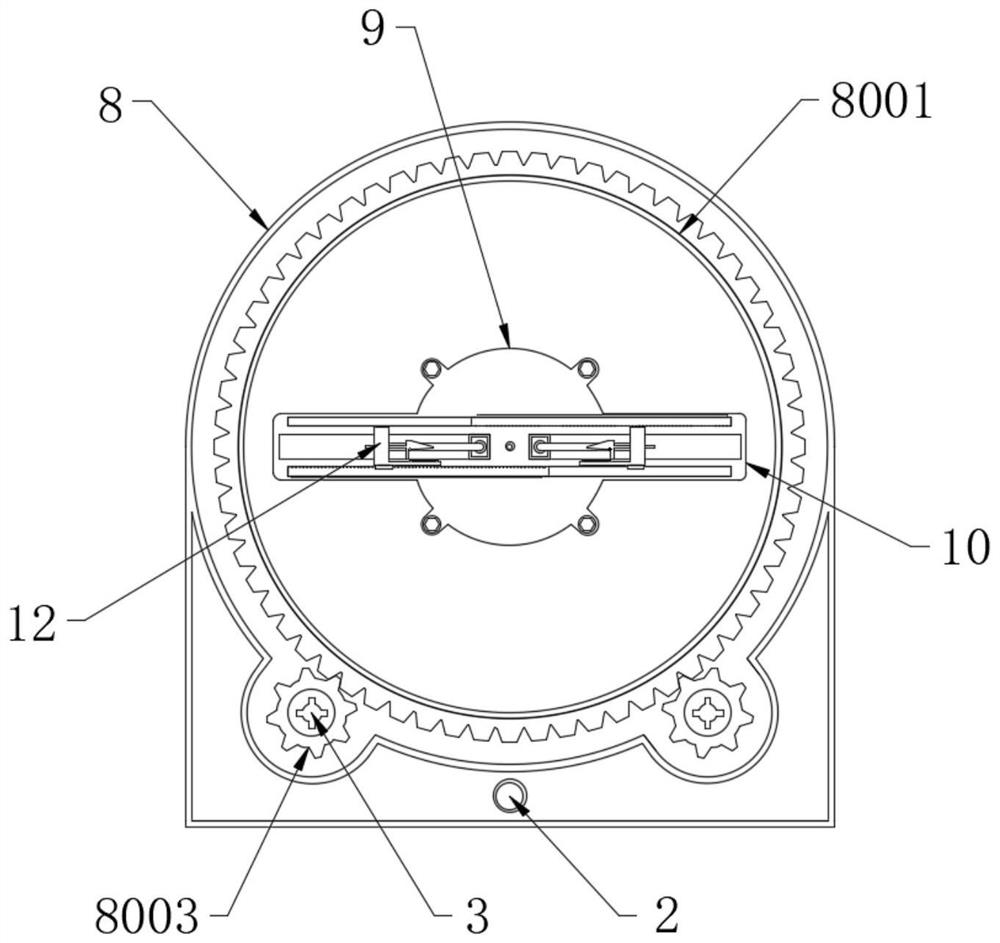

[0037] In this embodiment, the housing 8 includes a steering wheel 8001, a fixed rod 8002, a transmission wheel 8003 and a fixed plate 9, so

[0039] In this embodiment, the fixing plate 9 includes a third motor 9001 and a fixing frame 10, and the third motor 9001 is installed

[0041] In this embodiment, the fixing frame 10 includes a first chute 1001, a second chute 1002, a transmission bar 1003, and a slider

[0043] In the present embodiment, the adjusting disc 11 includes a tooth 1101, a first elastic piece 1102, an inner ring 1103 and a second elastic piece

[0046] Specifically, the driven shaft 1202 cooperates with the spring shaft 1205 to generate a reset rotation after the rotation, thereby driving the movement.

[0049] In this embodiment, the movable plate 13 includes an engaging block 1301, a first inner groove 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com