Chip bonding pad structure of PCB

A chip pad, PCB board technology, applied in the direction of electrical connection of printed components, printed circuit components, electrical components, etc., can solve the problems of reducing the line width and the distance between the pads, etc., to ensure the yield and continuous wiring. The effect of impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

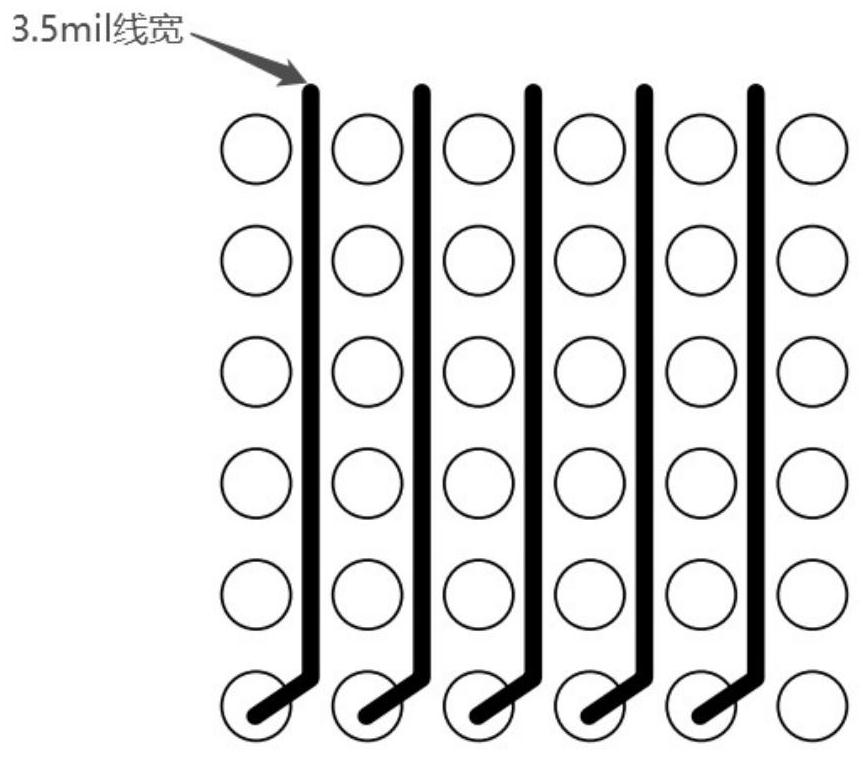

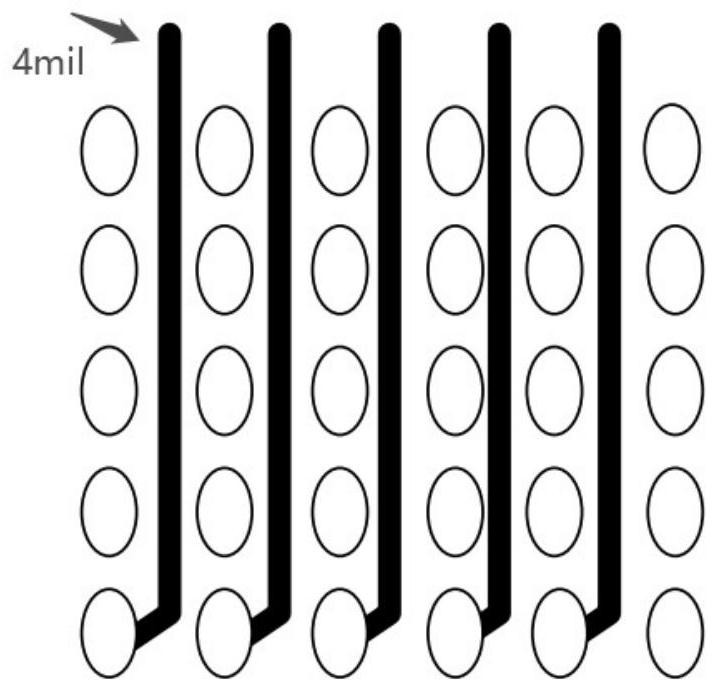

[0015] The chip pad structure of the PCB board of the present embodiment, as figure 2 As shown, several chip pads are included, and several chip pads are arranged in m rows and n columns. Each chip pad is elliptical, and the elliptical chip pads are arranged in rows and columns, and all the elliptical chip pads have the same long axis direction and the same short axis direction. The position between the minor axis and the minor axis is used for routing.

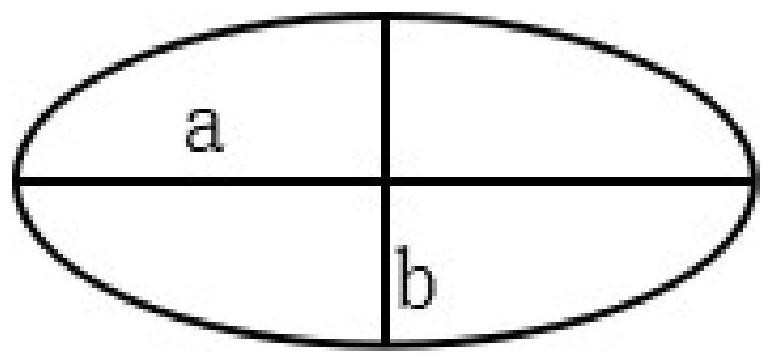

[0016] Such as image 3 As shown, a is defined as the major axis of the ellipse, and b is defined as the minor axis of the ellipse.

[0017] The consistent interpretation of the direction of the major axes of the ellipses means that the major axes of each ellipse are in the direction of the X axis, or they are all in the direction of the Y axis. The same is true for the direction of the minor axis.

[0018] In the chip pad of the present invention, by changing the circular pad into an ellipse with an equal area, the area...

Embodiment 2

[0020] The chip pad structure of the PCB board of the present embodiment, as Figure 4 As shown, several chip pads are included, and several chip pads are arranged in m rows and n columns. Each chip pad is rectangular, and the rectangular chip pads are arranged in rows and columns, and all rectangular chip pads have the same length direction and the same width direction. The position between width and width is used for wiring.

[0021] The direction of the length of the rectangles is consistently interpreted as: the length of each rectangle is in the direction of the X-axis, or in the direction of the Y-axis. Same goes for the width direction.

[0022] For the chip pad of this embodiment, by changing the circular pad into a rectangle with the same area, the area of the pad does not change, but the shape changes. The area does not change to ensure that the same area of the PCB board can accommodate the same number of BGA (BallGrid Array, ball grid array package) balls, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com